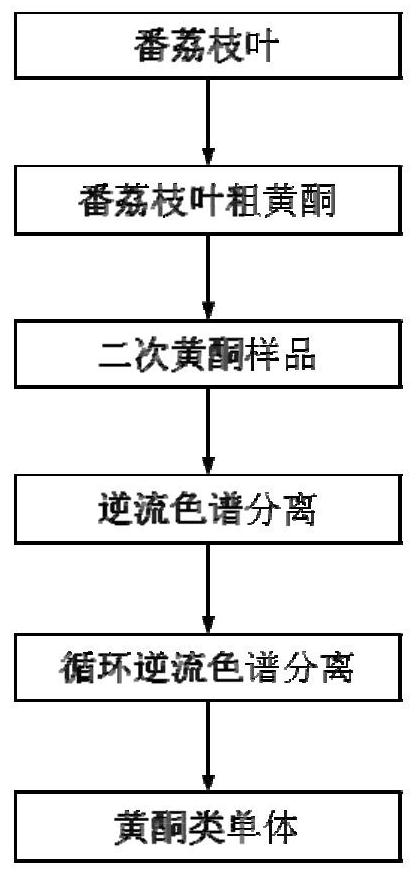

A method for separating flavonoids in custard apple leaves

A technology of custard apple leaves and flavonoids, which is applied in the field of high-purity flavonoid monomers, can solve the problems of low preparation efficiency of flavonoid compound monomers, low sample purity, difficult preparation volume, etc., and achieve good anti-oxidation and hypoglycemia in vitro Activity, simple production process, saving the effect of preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] 1.1 Sample extraction

[0068] The dried custard apple leaves (2kg) were completely crushed into powder, extracted twice with 5L of 95% ethanol under reflux, each time for 2h, and then the extract was filtered with a vacuum filter. Combine all extracts and concentrate until there is no alcohol smell, then use equal proportion of petroleum ether to extract, degrease, and then use equal proportion of n-butanol to extract the water phase twice, n-butanol extract is concentrated under reduced pressure, dried to obtain the concentrate 62g, that is, a sample of crude flavonoids. The primary crude flavonoid sample is subjected to secondary degreasing, the secondary degreasing solvent is petroleum ether / ethyl acetate / methanol / water (5:5:2:8, v / v), the lower phase is concentrated under reduced pressure, dried, and the total flavonoid sample is obtained 17.6g.

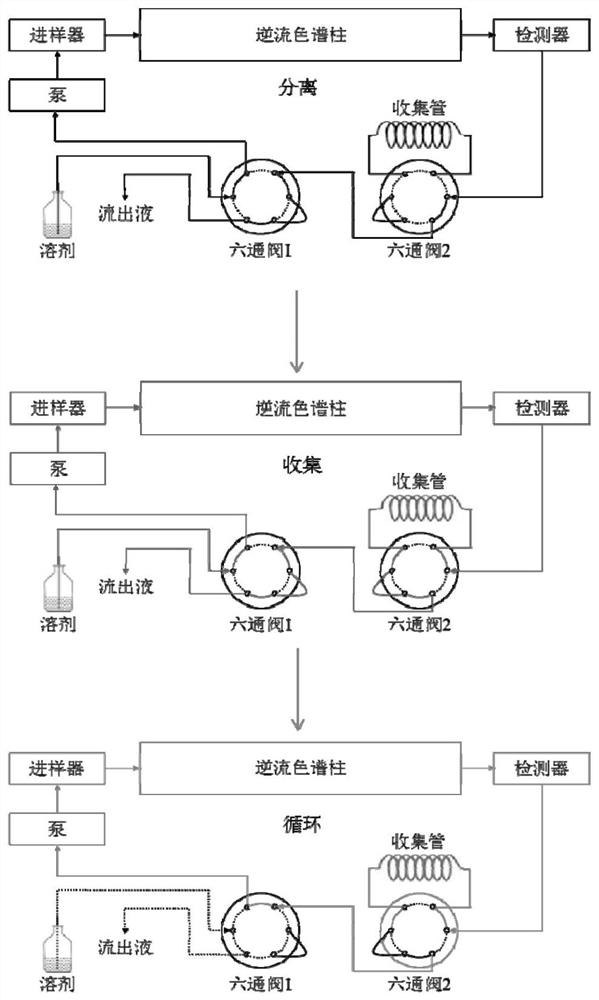

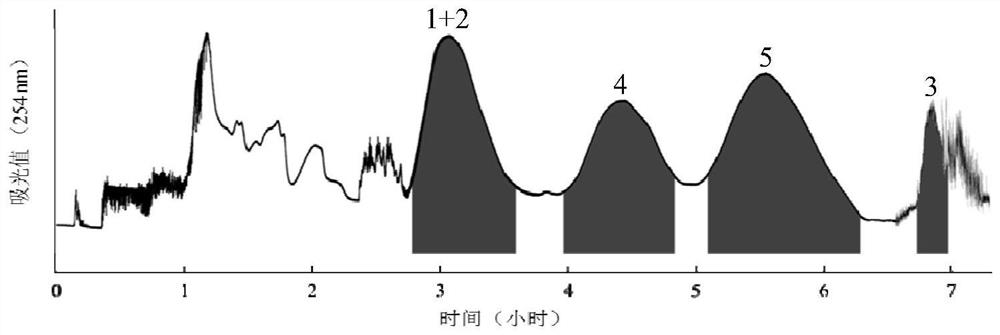

[0069] 1.2 Separation and purification of flavonoid monomers using on-line collection and circulating countercurrent ...

Embodiment 2

[0086] 1. Sample Extraction

[0087] The dried custard apple leaves (2kg) were completely crushed into powder, extracted twice with 5L of 95% ethanol under reflux, each time for 2h, and then the extract was filtered with a vacuum filter. Combine all extracts and concentrate until there is no alcohol smell, then use equal proportion of petroleum ether to extract, degrease, and then use equal proportion of n-butanol to extract the water phase twice, n-butanol extract is concentrated under reduced pressure, dried to obtain the concentrate And carry out secondary degreasing, the secondary degreasing solvent system is petroleum ether / ethyl acetate / methanol / water (5:5:2:8, v / v), the lower phase is concentrated under reduced pressure, dried, and obtains the total sample of flavonoids .

[0088] 2.1 Separation of total flavonoids from custard apple leaves by linear gradient high-speed countercurrent chromatography

[0089] The specific operation steps are: adopt a semi-preparative h...

Embodiment 3

[0102] 1. Method

[0103] 1. Evaluation method of antioxidant activity

[0104] DPPH (2.5 mg) was dissolved in 100 mL of ethanol to prepare a standard solution with a concentration of 25 μg / mL. Serial dilutions were used to provide ethanol standard solutions at concentrations of 0, 5, 10, 15, 20 and 25 μg / mL. The absorbance values of the six solutions were measured at 517 nm by UV spectrophotometry to prepare a standard curve. DPPH (2.0 mg) was dissolved in 100 mL of ethanol to prepare a standard solution with a concentration of 20 μg / mL. Solutions containing different concentrations of L-ascorbic acid (positive control), crude extracts and monomeric compounds were prepared as test samples. Add 3mL of the standard solution into a 10mL colorimetric tube together with 2mL of the solution from the sample set. For the control group, add 3mL of ethanol and 2mL of sample solution into a 10mL colorimetric tube, and use 3mL of standard solution containing 2mL of ethanol as a bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com