Waste cutting emulsion wastewater treatment system and waste cutting emulsion wastewater treatment method

A waste water treatment system and waste water technology, applied in the direction of metallurgical waste water treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of large impact load of water volume, limited biochemical improvement, poor system operation stability, etc. Effect of water and load, improvement of biodegradability, and reduction of transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

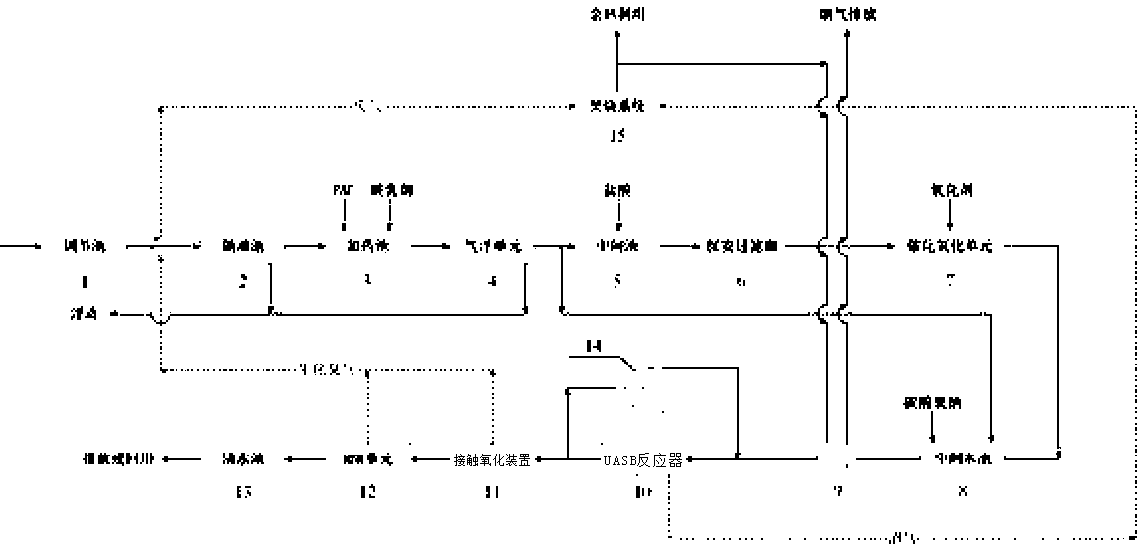

Image

Examples

Embodiment 1

[0051] 1) The wastewater enters the regulating tank for homogenization and equalization, and then enters the grease trap to initially remove the suspended mineral oil, animal and vegetable oil in the wastewater. The scum produced in the grease trap enters the sewage together with the remaining activated sludge generated by the biochemical system The sludge disposal system realizes harmless disposal; the effluent from the oil separation tank enters the dosing tank, where PAC (polyaluminum chloride) and demulsifier are added to the dosing tank, and then enters the air flotation unit to remove the oily substances and suspended oil in the wastewater. The flocculant used in the dosing pool is polyaluminium chloride, the concentration is 4~8wt%, and the dosage is 10~200ppm; the demulsifier used in the dosing pool is inorganic demulsifier, the concentration is 2~6wt% , the dosage is 0.5~20ppm;

[0052] 2) The effluent of the air flotation unit enters the intermediate pool, and the su...

Embodiment 2

[0061] 1) The wastewater enters the regulating tank for homogenization and equalization, and then enters the grease trap to initially remove the suspended mineral oil, animal and vegetable oil in the wastewater. The scum produced in the grease trap enters the sewage together with the remaining activated sludge generated by the biochemical system The sludge disposal system realizes harmless disposal; the effluent from the oil separation tank enters the dosing tank, where PAC (polyaluminum chloride) and demulsifier are added to the dosing tank, and then enters the air flotation unit to remove the oily substances and suspended oil in the wastewater. The flocculant used in the dosing pool is polyaluminium chloride, the concentration is 4~8wt%, and the dosage is 10~200ppm; the demulsifier used in the dosing pool is inorganic demulsifier, the concentration is 2~6wt% , the dosage is 0.5~20ppm;

[0062] 2) The effluent of the air flotation unit enters the intermediate pool, and the su...

Embodiment 3

[0071] 1) The wastewater enters the regulating tank for homogenization and equalization, and then enters the grease trap to initially remove the suspended mineral oil, animal and vegetable oil in the wastewater. The scum produced in the grease trap enters the sewage together with the remaining activated sludge generated by the biochemical system The sludge disposal system realizes harmless disposal; the effluent from the oil separation tank enters the dosing tank, where PAC (polyaluminum chloride) and demulsifier are added to the dosing tank, and then enters the air flotation unit to remove the oily substances and suspended oil in the wastewater. The flocculant used in the dosing pool is polyaluminium chloride, the concentration is 4~8wt%, and the dosage is 10~200ppm; the demulsifier used in the dosing pool is inorganic demulsifier, the concentration is 2~6wt% , the dosage is 0.5~20ppm;

[0072] 2) The effluent of the air flotation unit enters the intermediate pool, and the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com