Micro-nano organic fertilizer

An organic fertilizer, micro-nano technology, applied in the direction of organic fertilizer, organic fertilizer preparation, fertilizer form, etc., can solve the problems of chemical residues, low absorption rate, poor fertilizer efficiency, etc., to reduce the incidence of insect pests, improve soil environment, soil The effect of reducing disease transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

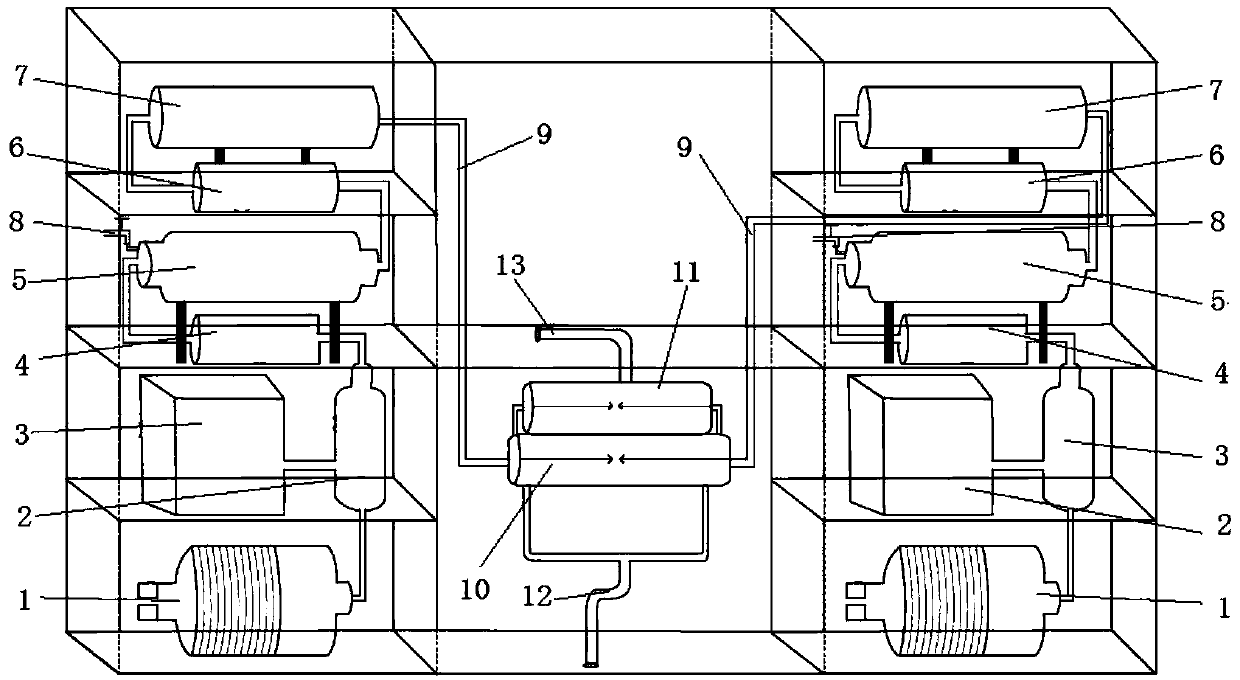

Method used

Image

Examples

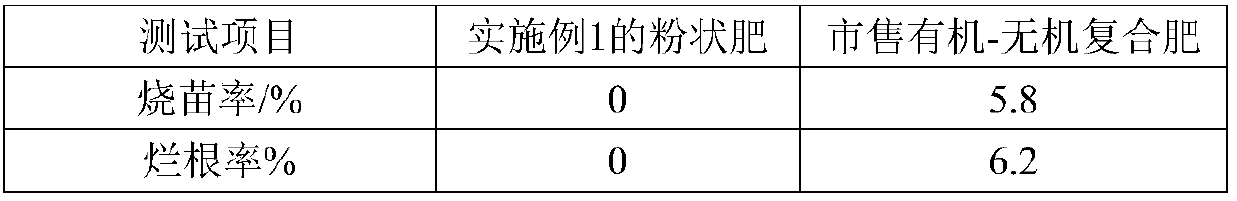

Embodiment 1

[0044] Organic fertilizer, its specific preparation process is:

[0045] A. Pretreatment: On March 20, 2017, the livestock and poultry manure produced by the farm was stirred after removing impurities such as stones, branches, and metals in the livestock and poultry manure. The mass was 0.7 tons, and its water content was tested to be 55.8% (weigh about 5g of the sample, then place it in a 105°C oven and dry it to constant weight, then follow the formula Calculate water content, test in parallel three times, take its average value as the final result), then add 0.3 tons of organic waste (straw and mushroom dregs are formed according to the mass ratio of 3:1) and microbial fermentation agent (consumption is every 7m 3 Add 50g of microbial starter to feces and organic matter. The microbial starter is composed of yeast, spore, lactic acid bacteria, faecal streptococcus, xylanase and cellulase in a mass ratio of 1:1:1:1; 1:1 ), and mix well;

[0046] B. Fermentation: Transport ...

Embodiment 2-4

[0072] Except for the following parameters, other parameter settings are the same as in Example 1

[0073] Example 2-4

[0074]

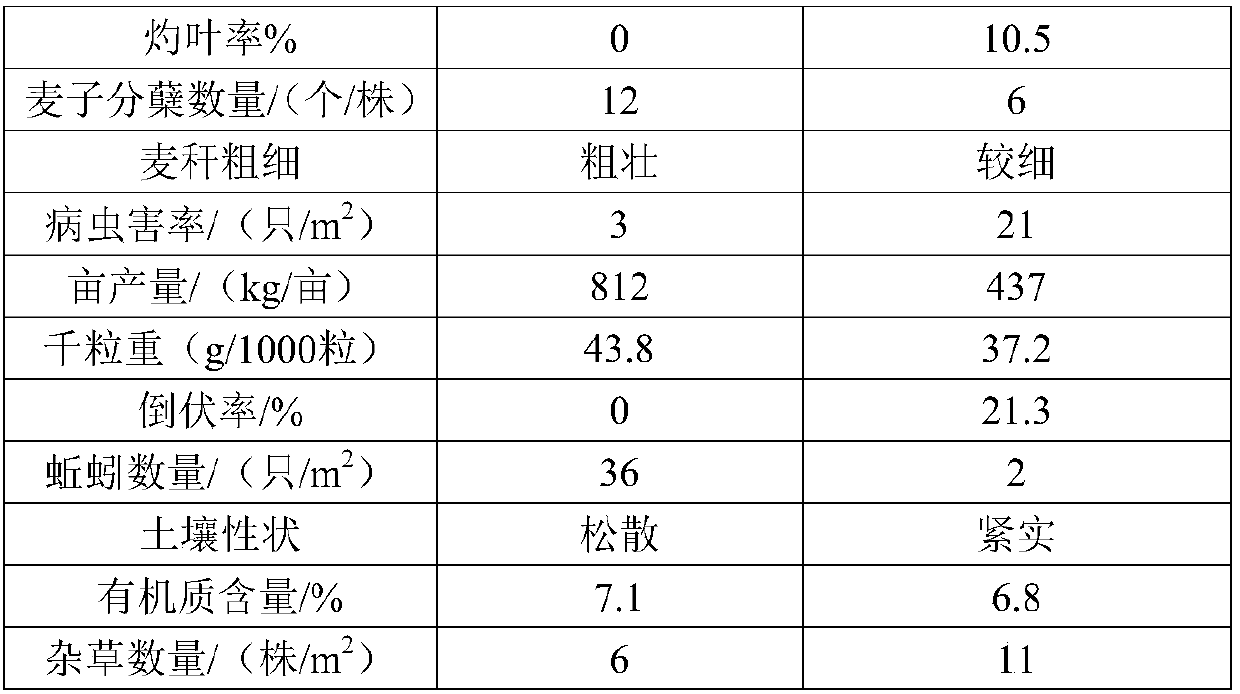

[0075] soybean planting test

[0076] Will be planted with the same kind, the soybean field that the area of same batch is 11.2 mus is divided into two on average, and one of them fertilizes with the powdery fertilizer that embodiment 2 makes, and another piece uses commercially available organic-inorganic compound fertilizer (purchased from Beijing Shuanglong Arms Technology Co., Ltd.) fertilized, and the two plots were fertilized three times: a basal manure (amount of 150kg / mu) was applied before sowing, and a fertilizer was applied once at the seedling stage and before flowering (amount of 50kg / mu was applied each time). , diluted 10 times), the fertilization method is spraying, except that the fertilizer is different, the other management methods of the two plots are the same. Detect the burning seedling rate, rotten root rate, and burnin...

Embodiment 5

[0110] Organic fertilizer, its specific preparation process is:

[0111] A. Pretreatment: On March 26, 2017, the livestock and poultry manure produced by the farm was stirred after removing impurities such as stones, branches, and metals in the livestock and poultry manure. The mass was 0.7 tons, and the water content was tested to be 61.3% (the detection method is the same as the water content detection method in Example 4), dehydrated to 58.4% (weighing about 5g of the sample, then placing it in a 105°C oven and drying it to constant weight, then according to the formula Calculate water content, test in parallel three times, take its average value as final result), then add 0.3 tons of organic matter (straw and mushroom dregs are formed according to the mass ratio of 3:1) and microbial fermentation agent (consumption is every 7m 3 Add 50g of microbial starter to feces and organic matter. The microbial starter is composed of yeast, spore, lactic acid bacteria, faecalis, xyla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com