A kind of method for continuously synthesizing white carbon black and sodium fluoride

A technology of silica and sodium fluoride, which is applied in the chemical industry, can solve problems such as wide particle size distribution, reduced heat transfer efficiency, poor quality and performance of silica, and achieve narrow particle size distribution, stable silicon content, and reduced energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

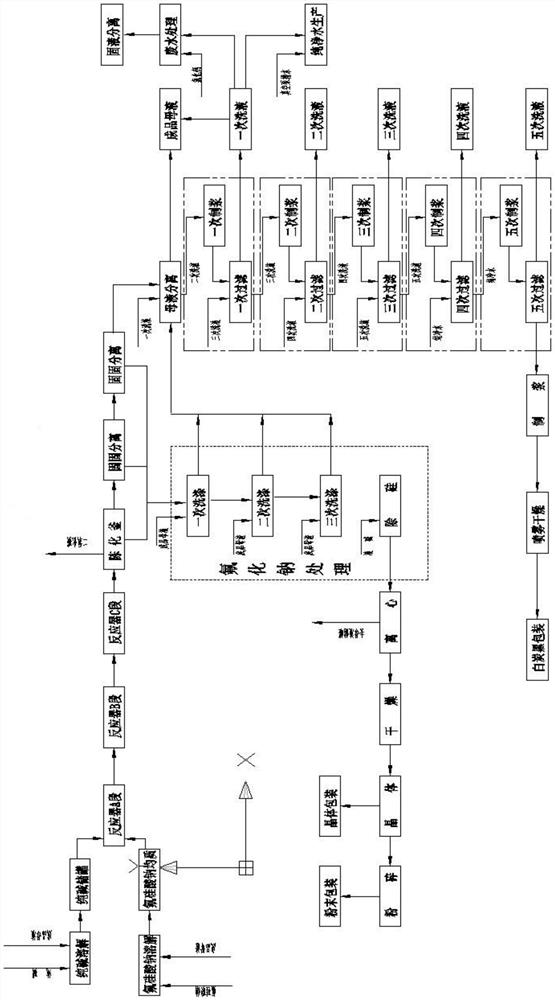

Image

Examples

Embodiment 1

[0056] The preparation concentration is 0.48 mol / L Soda ash solution, and a concentration of 0.83 mol / L The sodium fluorosilicate solution is synchronously pumped into the feed port of the tubular reactor to form a mixed solution; when pumping, the molar ratio of soda ash and sodium fluorosilicate is controlled to be 2.3, and the mixed solution flows first After passing through the reaction tube A with a temperature of 79 °C; then through the reaction tube B with a temperature of 83 °C; min, reaching the discharge port of the tubular reactor to obtain the post-reaction liquid, and the content of silica in the post-reaction liquid is: 1g / 100ml. That It flows out from the discharge port to the aging kettle; the post-reaction liquid enters the aging kettle from the tubular reactor, and the carbon dioxide is discharged from the upper part of the aging kettle for exhausting; the after-reaction liquid after exhausting passes through two The solid-solid separation device connec...

Embodiment 2

[0060] Prepare a soda ash solution with a concentration of 0.43mol / L and a sodium fluorosilicate solution with a concentration of 0.8mol / L, and pump the soda ash solution and the sodium fluorosilicate solution synchronously into the feed port of the tubular reactor to form a mixed solution; When pumping, the molar ratio of soda ash and sodium fluorosilicate is controlled to be 2.15, and the mixture first flows through reaction tube A with a temperature of 79 °C; then flows through reaction tube B with a temperature of 83 °C; and then flows through reaction tube C with a temperature of 87 °C, The flow rate of the mixed solution in the tubular reactor was 1.7m / s, which lasted 7.15min, and reached the outlet of the tubular reactor to obtain the post-reaction solution. At this time, the content of silica in the post-reaction solution was 0.96g / 100ml. . It flows out from the discharge port to the aging kettle; the post-reaction liquid enters the aging kettle from the tubular reacto...

Embodiment 3

[0064] Prepare a soda ash solution with a concentration of 0.46mol / L and a sodium fluorosilicate solution with a concentration of 0.81mol / L, and pump the soda ash solution and the sodium fluorosilicate solution synchronously into the feed port of the tubular reactor to form a mixed solution; When pumping, the molar ratio of soda ash and sodium fluorosilicate is controlled to be 2.27, and the mixture first flows through reaction tube A with a temperature of 79 °C; then flows through reaction tube B with a temperature of 83 °C; and then flows through reaction tube C with a temperature of 87 °C, The flow rate of the mixed solution in the tubular reactor was 1.9m / s, which lasted 6.4min, and reached the outlet of the tubular reactor to obtain the post-reaction solution. At this time, the content of silica in the post-reaction solution was 0.97g / 100ml. . It flows out from the discharge port to the aging kettle; the post-reaction liquid enters the aging kettle from the tubular reactor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com