A kind of amino functionalized magnetic ferric iron tetroxide nanoparticles and preparation method thereof

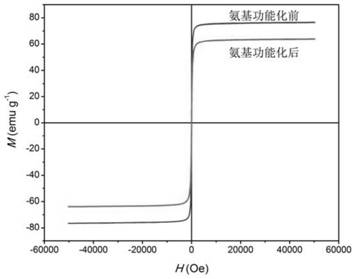

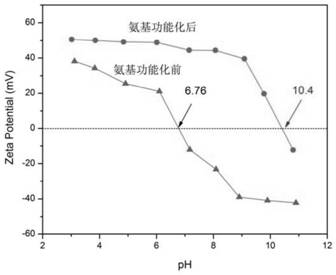

A technology of ferric tetroxide and amino functionalization, applied in chemical instruments and methods, iron oxide/iron hydroxide, nanotechnology, etc., can solve the problems of adsorption of unfavorable pollutants, secondary agglomeration, small specific surface area, etc. The effect of abundant surface active sites, high saturation magnetization, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

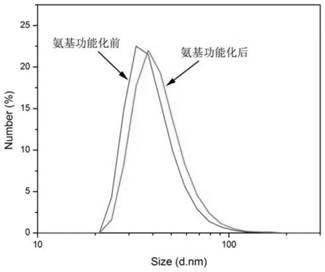

[0024] (1) Mix 15mmol anhydrous ferric chloride, 5mmol sodium hydroxide, 50mL ethylene glycol and 3.6ml deionized water and transfer to a three-necked flask, mix well, heat up to boiling, then keep boiling and reflux for 8h, stop react, cool to room temperature, separate and wash to obtain ferric oxide nanoparticles. figure 1 Shown is the transmission electron microscope (TEM) photo of the obtained iron ferric oxide nanoparticles. It can be seen from the figure that the average size of the obtained nanoparticles is between 20-40nm, with uniform particle diameter, moderate size, good dispersion and no agglomeration.

[0025] (2) Disperse 0.5 g of the ferric oxide nanoparticles obtained above in 100 ml of water, add 3 ml of APTES, and heat to 65 ° C under mechanical stirring; after 12 hours of reaction, stop stirring, cool to room temperature, separate and wash APTES modified ferric oxide nanoparticles were obtained. figure 2 Shown is a transmission electron microscope (TEM) p...

Embodiment 2

[0028] (1) Mix 30mmol anhydrous ferric chloride, 9.5mmol sodium hydroxide, 100mL ethylene glycol and 5ml deionized water and transfer to a three-necked flask, mix well, heat up to boiling, then keep boiling and reflux for 12h, stop react, cool to room temperature, separate and wash to obtain ferric oxide nanoparticles.

[0029] (2) Disperse 0.5 g of the ferric oxide nanoparticles obtained above in 100 ml of water, add 1 ml of APTES, and heat to 60 ° C under mechanical stirring; after 24 hours of reaction, stop stirring, cool to room temperature, separate and wash APTES modified ferric oxide nanoparticles were obtained.

Embodiment 3

[0031] (1) Mix 30mmol anhydrous ferric chloride, 10.5mmol sodium hydroxide, 100mL ethylene glycol and 6ml deionized water and transfer to a three-necked flask, mix well, heat up to boiling, then keep boiling and reflux for 6h, stop react, cool to room temperature, separate and wash to obtain ferric oxide nanoparticles.

[0032] (2) Disperse 0.5g of the ferric oxide nanoparticles obtained above in 100ml of water, add 5ml of APTES, and heat to 70°C under mechanical stirring; after 24 hours of reaction, stop stirring, cool to room temperature, separate and wash APTES modified ferric oxide nanoparticles were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com