Asphalt paint for ship anchor chains and preparation method of asphalt paint

A kind of asphalt paint and anchor chain technology, which is applied in the direction of asphalt paint, coating, anti-corrosion paint, etc., can solve the problems of easy peeling, poor wear resistance, and asphalt paint does not have wear resistance and corrosion resistance, and achieve stable chemical properties , strong wear resistance, perfect corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

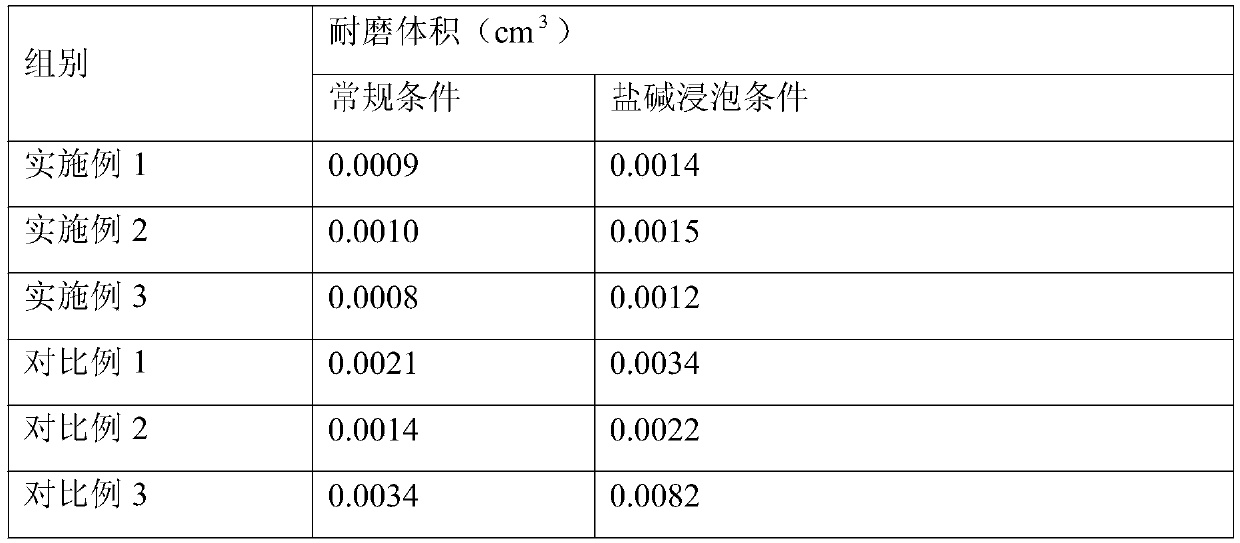

Examples

Embodiment 1

[0024] A kind of asphalt paint for ship anchor chains of the present embodiment comprises the following raw materials in parts by weight:

[0025] 40 parts of modified asphalt, 18 parts of polysebacyl-p-xylylenediamine resin, 10 parts of vinyl ester resin, 6 parts of N-β-hydroxyethyl-1,2-diaminoethane modified potassium titanate whiskers 3 parts, 3 parts cetyl bromide, 4 parts zinc phosphate, 3 parts aluminum silicate, 2 parts plagioclase powder, 20 parts ethylene glycol.

[0026] The modification method of the modified asphalt in this example is to first heat the asphalt to 120°C until the asphalt becomes fluid, then add graphite-loaded halloysite nanotubes to it, and then stir at a speed of 200-300r / min for 25min , followed by adding 3,4-ethylenedioxythiophene and full ether melamine polymer derivatives in turn, then lowering the temperature to room temperature at a rate of 2°C / min, and finally keeping the temperature and stirring for 30min at a stirring speed of 120r / min, s...

Embodiment 2

[0034] A kind of asphalt paint for ship anchor chains of the present embodiment comprises the following raw materials in parts by weight:

[0035] 45 parts of modified asphalt, 22 parts of polysebacyl-p-xylylenediamine resin, 14 parts of vinyl ester resin, 10 parts of N-β-hydroxyethyl-1,2-diaminoethane modified potassium titanate whiskers 7 parts, 7 parts cetyl bromide, 10 parts zinc phosphate, 6 parts aluminum silicate, 6 parts plagioclase powder, 30 parts ethylene glycol.

[0036] The modification method of the modified asphalt in this embodiment is to first heat the asphalt to 180°C until the asphalt becomes fluid, then add graphite-loaded halloysite nanotubes to it, then stir at a speed of 300r / min for 35min, and then Add 3,4-ethylenedioxythiophene and all-ether melamine polymer derivatives in turn, then lower the temperature to room temperature at a rate of 5°C / min, and finally keep stirring for 40min at a stirring speed of 160r / min, and the stirring is over. Modified as...

Embodiment 3

[0044] A kind of asphalt paint for ship anchor chains of the present embodiment comprises the following raw materials in parts by weight:

[0045] 42.5 parts of modified asphalt, 20 parts of polysebacyl-p-xylylenediamine resin, 12 parts of vinyl ester resin, 8 parts of N-β-hydroxyethyl-1,2-diaminoethane modified potassium titanate whiskers 5 parts, 5 parts of cetylpyridine bromide, 7 parts of zinc phosphate, 4.5 parts of aluminum silicate, 4 parts of plagioclase powder, and 25 parts of ethylene glycol.

[0046] The modification method of the modified asphalt in this embodiment is to heat the asphalt to 150°C until the asphalt becomes fluid, then add graphite-loaded halloysite nanotubes to it, and then stir at a speed of 250r / min for 30min, then Then add 3,4-ethylenedioxythiophene and all-ether melamine polymer derivatives in sequence, then lower the temperature to room temperature at a rate of 3.5°C / min, and finally keep stirring for 35min at a stirring speed of 140r / min, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com