A kind of monodisperse and superparamagnetic gold-magnetic composite microsphere and preparation method thereof

A superparamagnetic, composite microsphere technology, applied in diamagnetic/paramagnetic materials, magnetic objects, magnetic materials, etc., can solve the problems of poor dispersion, complex process and weakening of composite materials, and achieve good stability and repeatability. Good, avoid the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

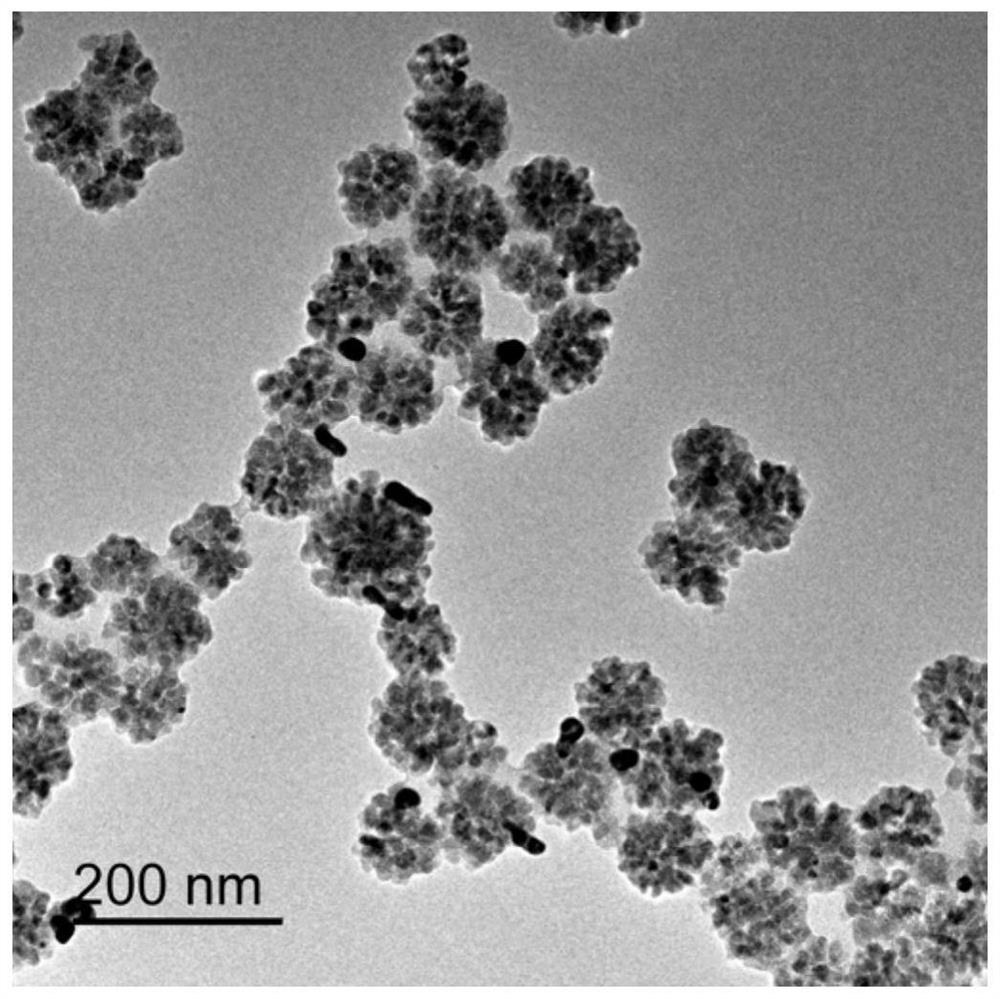

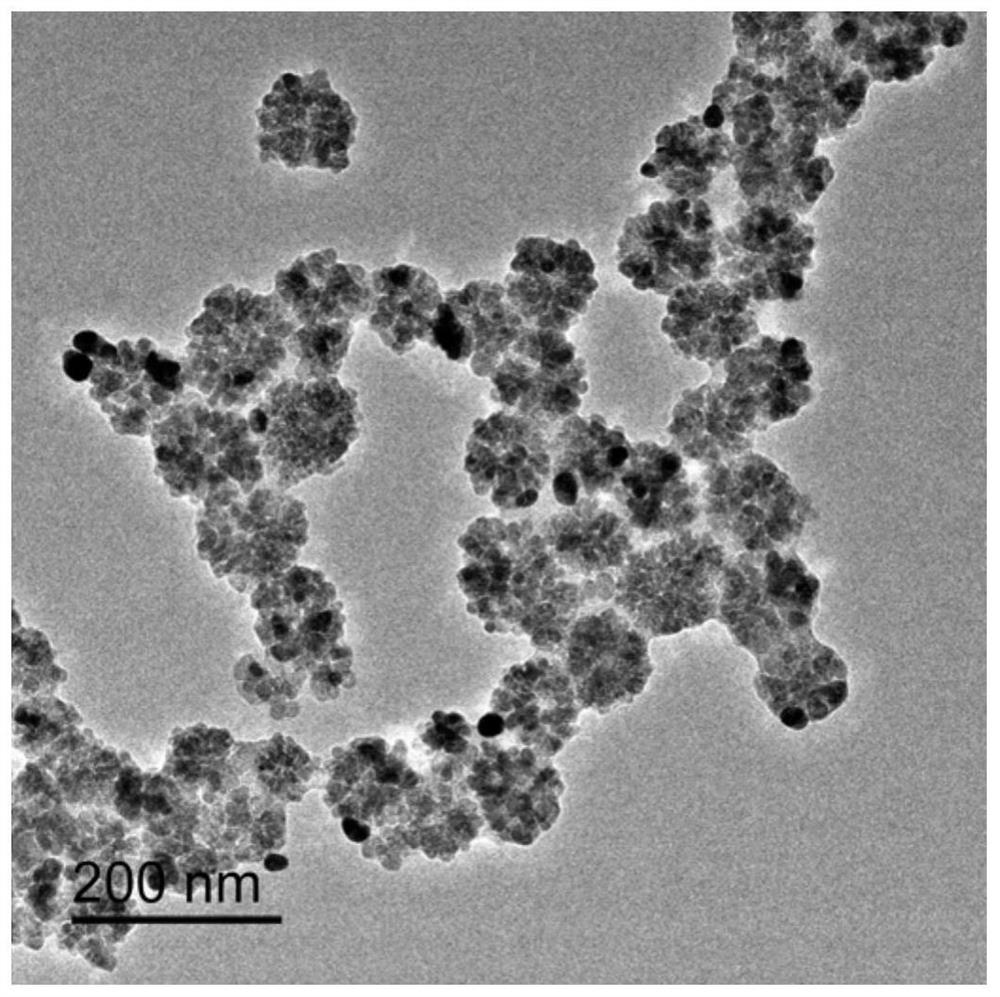

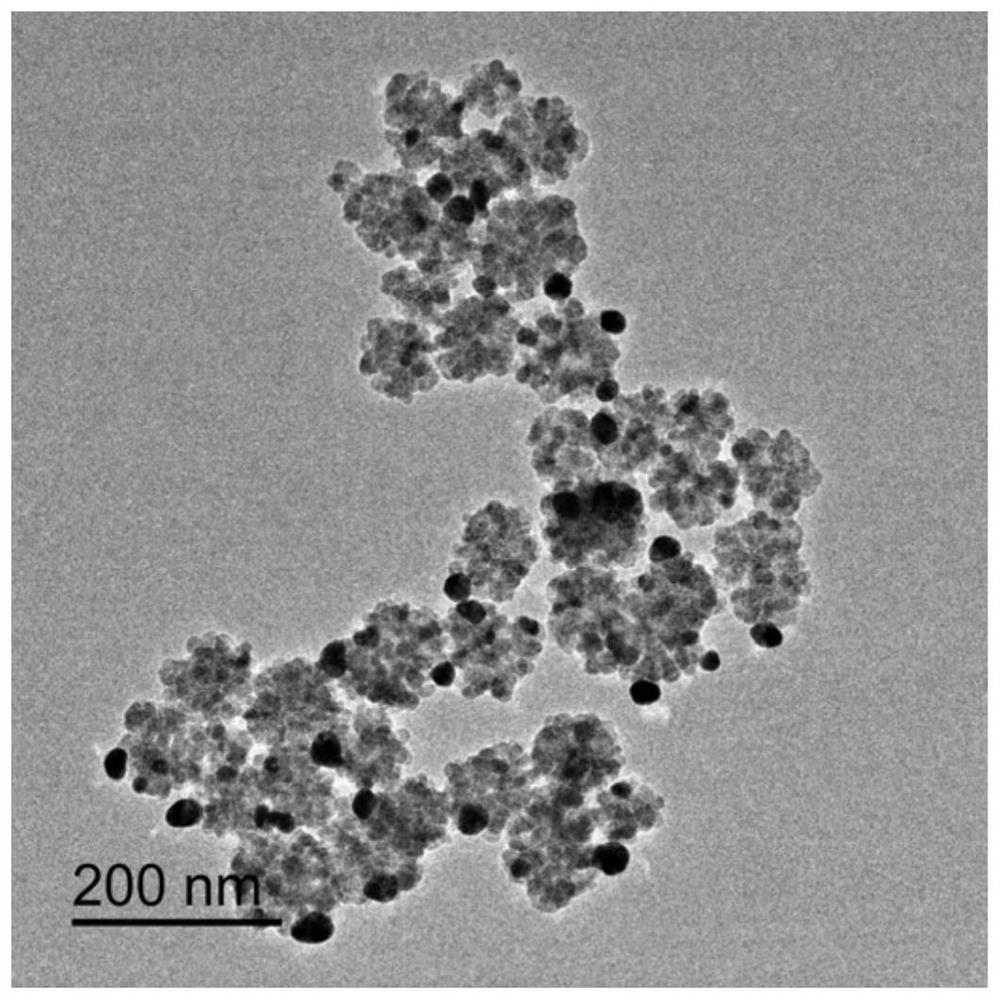

Image

Examples

preparation example Construction

[0036] The preparation method of the gold magnetic composite microsphere with monodisperse and superparamagnetic of the present invention comprises the steps:

[0037] (1) Preparation of mesoporous Fe by solvothermal method 3 o 4

[0038] FeCl 3 ·6H 2 O and sodium acetate are placed in a round-bottomed flask, and 1,2-propylene glycol solution is used as a solvent, stirred and ultrasonically dissolved to make it uniform, and then, the stirred mixture is heated to 90-110°C, and transferred to polytetrafluoroethylene for reaction In the kettle, react at 160-200°C for 8-10 hours. After the reaction, the black precipitate was collected by magnetic separation with a magnet, and washed several times alternately with ultrapure water and absolute ethanol until the cleaned supernatant was clear, and finally freeze-dried, and the obtained powder was mesoporous Fe 3 o 4 . where FeCl 3 ·6H 2 The molar ratio of O to sodium acetate is (0.1-0.15):1.

[0039] (2) Reducing agent on me...

Embodiment 1

[0044] (1) Preparation of mesoporous Fe by hydrothermal method 3 o 4

[0045] 5mmolFeCl 3 ·6H 2 O and 50mmol sodium acetate were placed in a round-bottomed flask, and 40ml of 1,2-propanediol solution was taken as a solvent, stirred and ultrasonically dissolved to make it uniform, and then, the stirred mixture was heated to 90°C, and transferred to polytetrafluoroethylene In the reaction kettle, react at 160°C for 8h. After the reaction, the black precipitate was collected by magnetic separation with a magnet, and washed several times alternately with ultrapure water and absolute ethanol until the cleaned supernatant was clear, and finally freeze-dried, and the obtained powder was mesoporous Fe 3 o 4 .

[0046] (2) Reducing agent on mesoporous Fe 3 o 4 surface modification

[0047] Take 0.05g of anhydrous sodium citrate and dissolve it in 100ml of ultrapure water. After the dissolution is complete, add 100mg of mesoporous Fe prepared in (1). 3 o 4 , the mixture was m...

Embodiment 2

[0051] (1) Preparation of mesoporous Fe by hydrothermal method 3 o 4

[0052] 5mmolFeCl 3 ·6H 2 O and 50mmol sodium acetate were placed in a round-bottomed flask, and 40ml of 1,2-propanediol solution was taken as a solvent, stirred and ultrasonically dissolved to make it uniform, and then, the stirred mixture was heated to 95°C, and transferred to polytetrafluoroethylene React for 10 hours at 180°C in the reactor. After the reaction, the black precipitate was collected by magnetic separation with a magnet, and washed several times alternately with ultrapure water and absolute ethanol until the cleaned supernatant was clear, and finally freeze-dried, and the obtained powder was mesoporous Fe 3 o 4 .

[0053] (2) Reducing agent on mesoporous Fe 3 o 4 surface modification

[0054] Take 0.10g of anhydrous sodium citrate and dissolve it in 100ml of ultrapure water. After the dissolution is complete, add 100mg of mesoporous Fe prepared in (1). 3 o 4 , the mixture was mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com