High-performance all-solid-state polymer electrochromic device and preparation method thereof

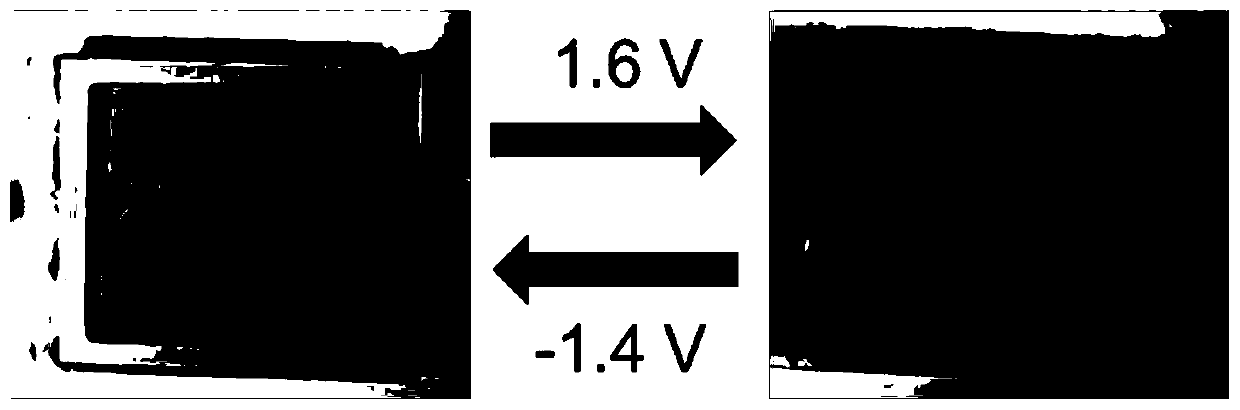

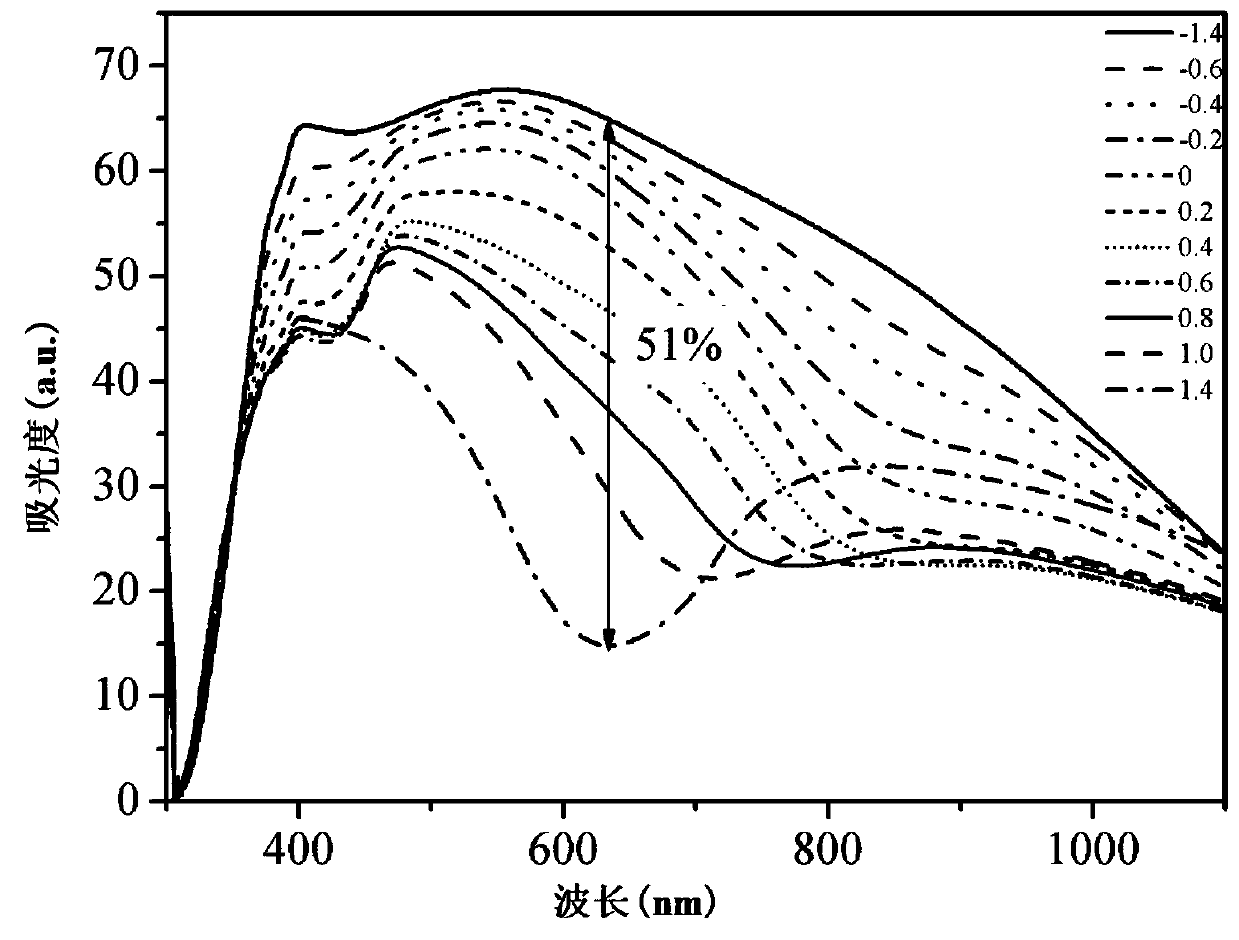

An all-solid polymer and electrochromic device technology, which is applied in the fields of instruments, nonlinear optics, optics, etc., can solve the problems of poor electrochemical stability and easy leakage of liquid device structure, and achieve low raw material cost and safe and non-toxic preparation process. Effects of pollution, high optical contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

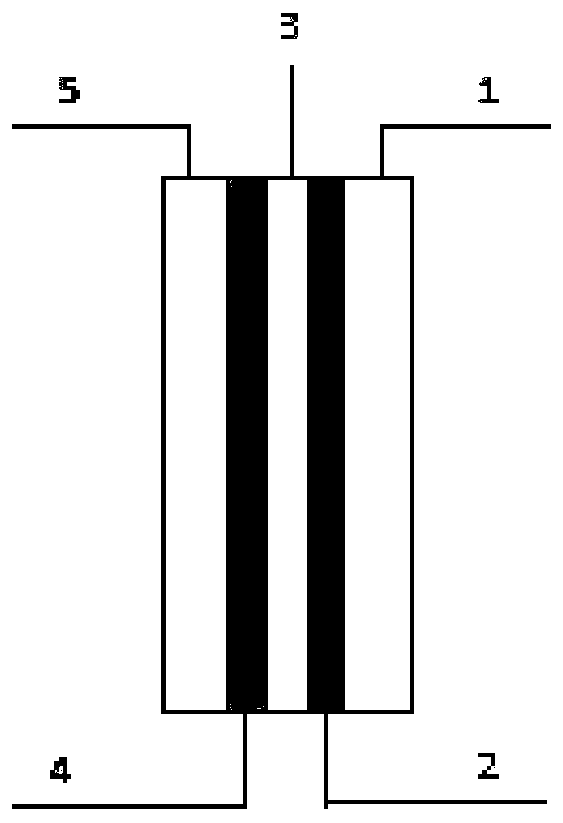

[0030] Embodiment 1: Preparation of electrochromic layer

[0031] In the three-electrode electrolysis system, use aniline (4.657g, 0.05mol) as a monomer, and sulfuric acid solution (98% concentrated sulfuric acid 10g, 0.1mol) as a supporting electrolyte to prepare 100mL blank electrolyte solution with a concentration of 1mol / L. 100 mL of monomer solution with a concentration of 0.5 mol / L was prepared, and the indium tin oxide (ITO) conductive glass was used as the working electrode, the platinum electrode was used as the auxiliary electrode, and the silver / silver chloride electrode was used as the reference electrode. Potential polymerization method for electrochemical polymerization, the constant potential used in the constant potential polymerization method is 0.8V, the polymerization power is 0.04C, and then dedoped at a negative potential of -0.4V for 60s to obtain a layer deposited on the ITO conductive substrate The transparent polymer film was washed with acetonitrile t...

Embodiment 2

[0032] Embodiment 2: the preparation of ion storage layer

[0033] 0.2525g of PEDOT:PSS was added into a 50ml beaker as a solute, 25g of deionized water was used as a solvent, and a 1% PEDOT:PSS aqueous solution was obtained after magnetic stirring for 2 hours. The solution was filtered three times by suction to remove undissolved solid residues in the solution, and the filtered filtrate was stored in a centrifuge tube for later use, and then spin-coated on a clean and dry ITO glass to obtain a PEDOT:PSS film. The mass ratio of PEDOT:PSS to water is 1:99, the rotation speed of the spin coating method is 1000rpm, and the time is 60s. Then, the PEDOT:PSS obtained by spin coating on the substrate was dried in an oven at 140° C. for 10 min to obtain a PEDOT:PSS polymer film.

Embodiment 3

[0034] Embodiment 3: Preparation of electrolyte layer

[0035] Put 2g of polymer binder PMMA and 8g of plasticizer PC in a 30ml reagent bottle, seal the reagent bottle and heat and swell in an oven at 75°C for 20h, and record it as system A; take 4g of acetonitrile and 10g of dichloro The mixed solution of methane is placed in a 30ml reagent bottle, and then 4g of supporting electrolyte LiBF 4 Add it into the mixed solvent, sonicate for 30 minutes until the electrolyte is completely dissolved, and record it as system B; mix the above system A with system B, and sonicate the resulting mixed system for 30 minutes until it is uniform, and remove part of the solvent by rotary evaporation to obtain a polymer gel electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com