Copolymer with polyphenyl polyether branched chain structure and preparation and application of copolymer

A technology of polyphenyl polyether and branched chain structure, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of increased viscosity of crude oil, poor emulsion stability, and reduced effect of emulsification and viscosity reduction, and achieve enhanced application performance, achieving viscosity and pour point reduction, and improving the fluidity of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

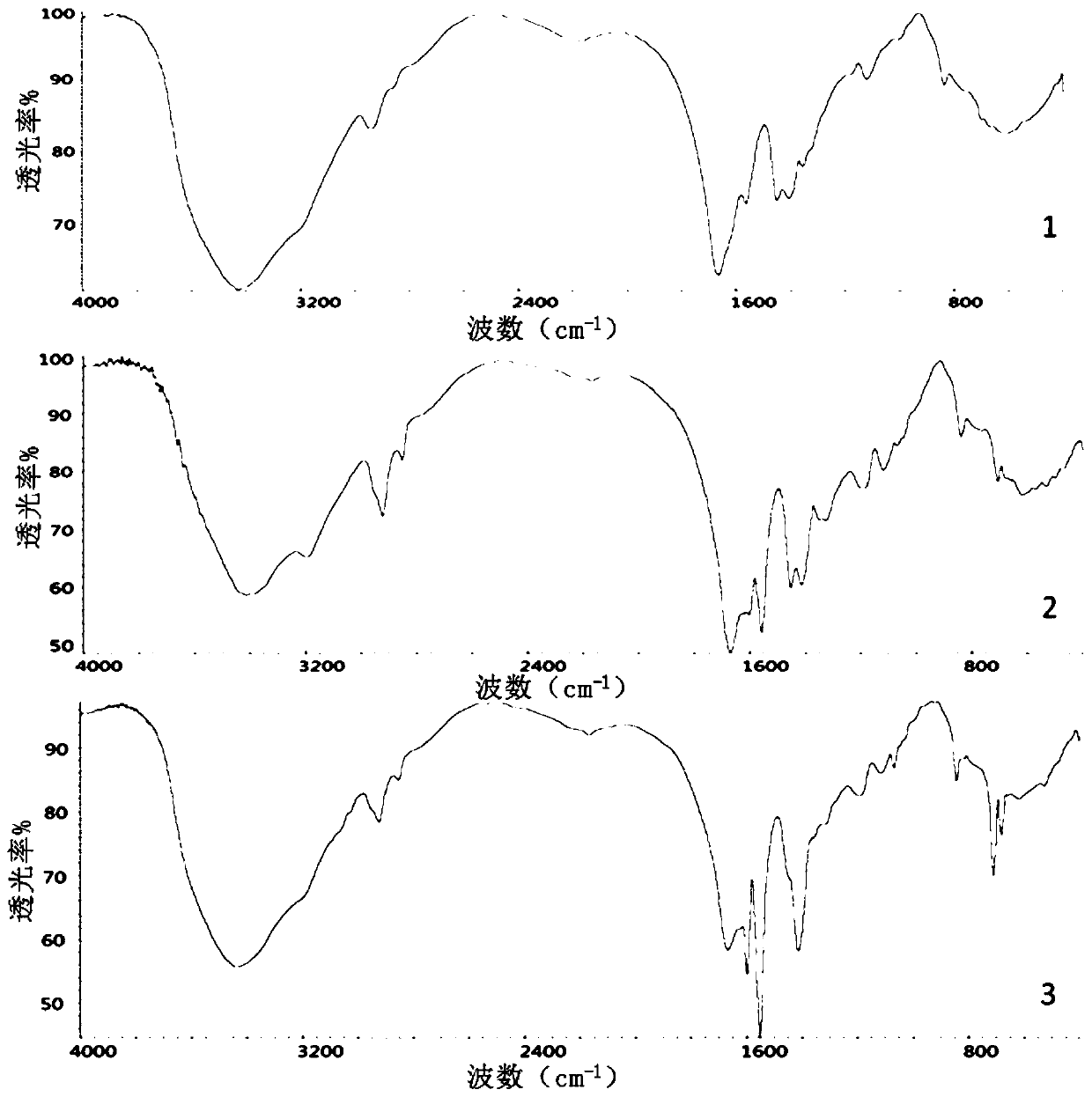

Embodiment 1

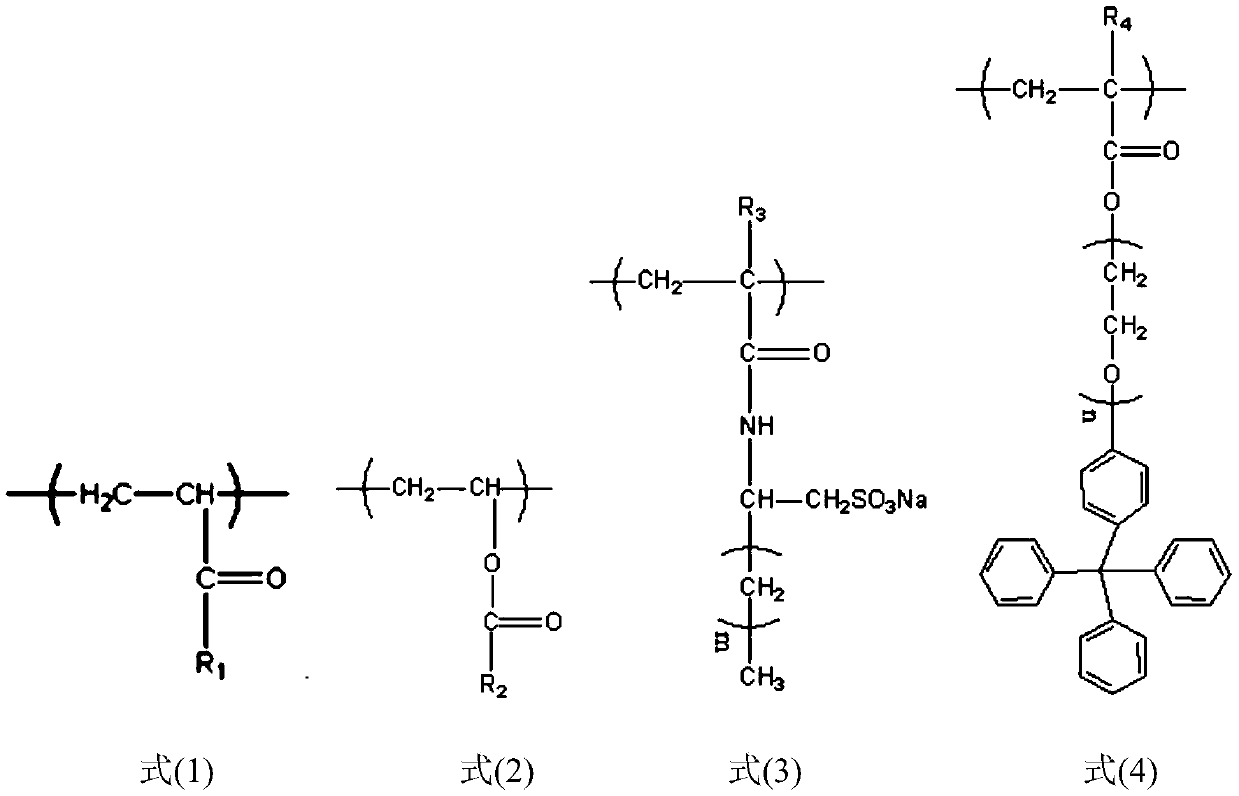

[0042] This embodiment provides a kind of copolymer containing polyphenyl polyether branched chain structure, and its preparation steps and raw material ratio are as follows:

[0043] Weigh 30.36g monomer E (R 1 for NH 2 , ie acrylamide), 0.86g lower unsaturated ester monomer F (R 2 for CH 3 ), 5.58g monomer G (R 3 H, m=9), 0.96g polyphenyl end-capped polyether monomer H (R 4 is H, n is 52) in the dissolver, add 104.60g deionized water, then add 4.08g sodium carbonate and stir to dissolve, adjust the temperature to 15°C, transfer the solution to the reactor, add 2.88g 3.0% ethylenediamine Disodium tetraacetate, 2.4g of 1.5% sodium bisulfite, 1.28g of 6% sodium formate and other polymerization aids, after nitrogen gas was passed for 30 minutes, 4.8g of 0.7% potassium persulfate, 3.2g of 0.25% 2,2- Nitrogen diisobutylamidine dihydrochloride, continue to pass nitrogen for 10 minutes, and then seal the reactor. After 4 hours, the reaction is completed, and the rubber block is...

Embodiment 2

[0047] This embodiment provides a copolymer containing polyphenyl polyether branched chain structure, the preparation steps and raw material ratio are:

[0048] Weigh 27.13g monomer E (R 1 for NH 2 , namely acrylamide), 1.68g lower unsaturated ester monomer F (R 2 for CH 3 ), 6.56g monomer G (R 3 H, m=9), 1.61g polyphenyl end-capped polyether monomer H (R 4 is H, n is 52) into the dissolver, add 103.2g deionized water, then add 4.18g sodium carbonate, 0.6g sodium lauryl sulfate and stir to dissolve, adjust the temperature to 13°C, and transfer the solution to the reactor , add 3.18g of 3.0% disodium ethylenediaminetetraacetic acid, 3.53g of 1.5% sodium bisulfite, 1.38g of 6% sodium hypophosphite and other polymerization aids, after passing through nitrogen for 30min, add 5.81g of 0.7% super Ammonium sulfate, 4.74g of 0.25% azobisisobutylimidium hydrochloride, continue to pass nitrogen for 10 minutes and then seal the reactor. After 4 hours, the reaction is completed, and ...

Embodiment 3

[0051] This example provides a copolymer containing polyphenyl polyether branched chain structure. The preparation steps are the same as in Example 1 (without adding alkali for neutralization). The ratio of raw materials is shown in Example 3. The molecular weight of the obtained polymer is 4.158 million.

[0052] This implementation provides a kind of copolymer containing polyphenyl polyether branched chain structure, preparation steps and raw material proportioning are:

[0053] Weigh 25.20g monomer E (R 1 is ONa, namely acrylic acid), 2.10g lower unsaturated ester monomer F (R 2 for CH 3 ), 7.11g monomer G (R 3 is H, m=9), 2.8g polyphenyl end-capped polyether monomer H (R 4 is H, n is 32) in the dissolver, add 109.34g of deionized water, then add 1.2g of sodium lauryl sulfate and stir to dissolve, adjust the temperature to 13°C, transfer the solution to the reactor, add 2.88g of 3.0% disodium ethylenediaminetetraacetic acid, 4.3g of 1.5% sodium formaldehyde sulfoxylate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com