Alkaline cyanide-free electroplating zinc-nickel alloy additive and electroplating liquid

A technology of electro-galvanized nickel and additives, applied in the field of electro-galvanized nickel alloy, can solve the problems of poor coating gloss, poor corrosion resistance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

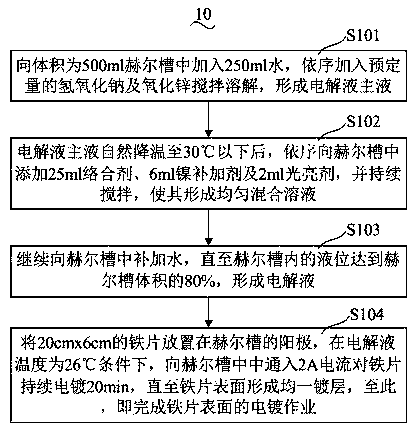

Embodiment 1

[0022] The invention provides an alkaline cyanide-free electroplating zinc-nickel alloy additive. The alkaline cyanide-free electroplating zinc-nickel alloy additive includes the following components in parts by mass: 50 parts of complexing agent, the complexing agent includes hydroxycarboxylic acid, amine and polyamine compounds, specifically, the complexing agent includes 12 parts of α-aminobutyric acid of 20g / L, 16 parts of diethanolamine of 120g / L, and N,N,N',N' of 160 / L - 15 parts of tetrahydroxyethylethylenediamine and 17 parts of derivatives of triethylenetetramine of 160 / L; 4 parts of brightening agent, brightening agent includes brightening main agent, nonionic surfactant and whitening agent, specifically, The brightener includes 1 part of diethoxybutynediol ether of 10g / L, 1 part of the reactant of triethylenetetramine and epichlorohydrin of 100g / L, 0.3 part of aromatic aldehyde of 50g / L, 20g / L 0.9 part of nicotinic acid derivative of L and 0.8 part of coumarin of 10...

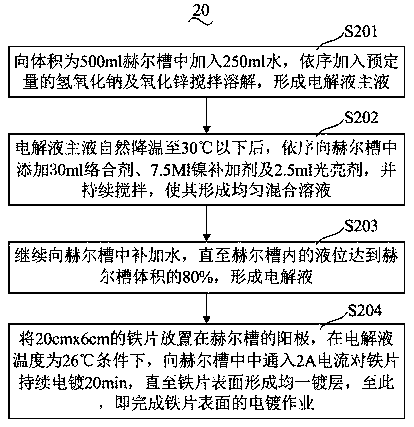

Embodiment 2

[0040] The invention provides an alkaline cyanide-free electroplating zinc-nickel alloy additive. The alkaline cyanide-free electroplating zinc-nickel alloy additive comprises the following components in parts by mass: 60 parts of complexing agent, the complexing agent includes hydroxycarboxylic acid, amine and polyamine compounds, specifically, the complexing agent includes 14 parts of tartaric acid of 30g / L, 18 parts of triethanolamine of 150g / L, 17 parts of polybutenylamine of 220g / L and 170g / L of ethylene glycol 21 parts of amine; 5 parts of brightening agent, brightening agent comprises bright main agent, nonionic surfactant and whitening agent, concrete, this brightening agent comprises 1.5 parts of propanesulfonic acid pyridinium salts of 20g / L, 110g / L 1.2 parts of reactants of diethylenetriamine and epichlorohydrin, 0.3 parts of 65g / L aromatic aldehyde, 1.2 parts of 30g / L nicotinic acid derivatives and 0.8 parts of 15g / L triethanolamine; 15 parts of nickel supplement ,...

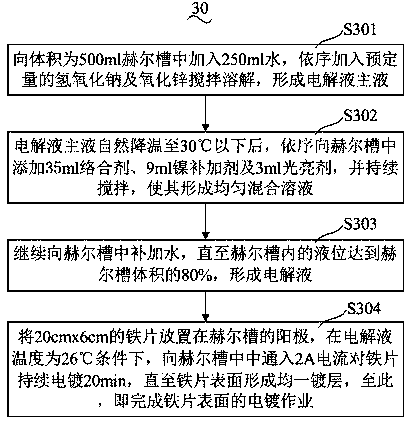

Embodiment 3

[0051] The invention provides an alkaline cyanide-free electroplating zinc-nickel alloy additive. The alkaline cyanide-free electroplating zinc-nickel alloy additive comprises the following components in parts by mass: 70 parts of complexing agent, the complexing agent includes hydroxycarboxylic acid, amine Classes and polyamine compounds, specifically, the complexing agent includes 16 parts of citric acid of 40g / L, 20 parts of tetraethylenepentamine of 220g / L, 20 parts of polypropyleneamine of 260g / L and 20 parts of polyacrylamine of 260g / L 24 parts of hexamethylenetetramine; 6 parts of brightening agent, brightening agent includes brightening main agent, nonionic surfactant and whitening agent, specifically, this brightening agent comprises the N-phenyl-3-carboxylate of 30g / L 2 parts of pyridine chloride, 1.5 parts of the reaction product of 120g / L sodium propargyl sulfonate and epichlorohydrin, 0.5 parts of 80g / L aromatic aldehyde, 1.2 parts of 40g / L nicotinic acid derivativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com