Saccharomyces cerevisiae highly producing C6-C10 ethyl esters and construction method and purpose of saccharomyces cerevisiae

A C6-C10, Saccharomyces cerevisiae technology, applied in the breeding of industrial microorganisms, C6-C10 ethyl ester-producing Saccharomyces cerevisiae and its construction, can solve the problems of affecting the yield of raw materials, low efficiency, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

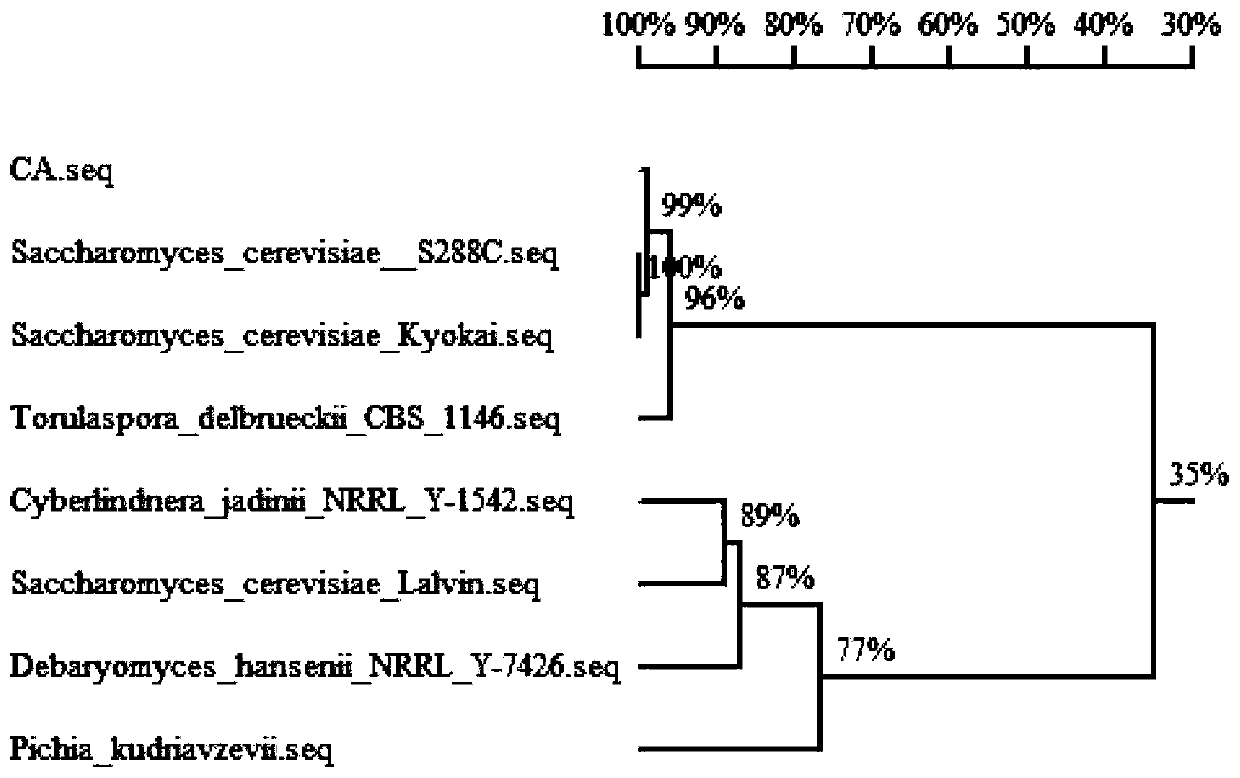

[0102] Example 1: Construction of high-yield C6-C10 ethyl ester Saccharomyces cerevisiae strain

[0103]The starting strain used in this example is Saccharomyces cerevisiae CA in Angelia yeast, and the strain preservation number is CGMCCNo.18670. The Escherichia coli DH5a was purchased from Takara Company. The YPD medium is a general complete medium, and the solid medium contains 2% imported agar powder.

[0104] The main construction process of the strain is as follows:

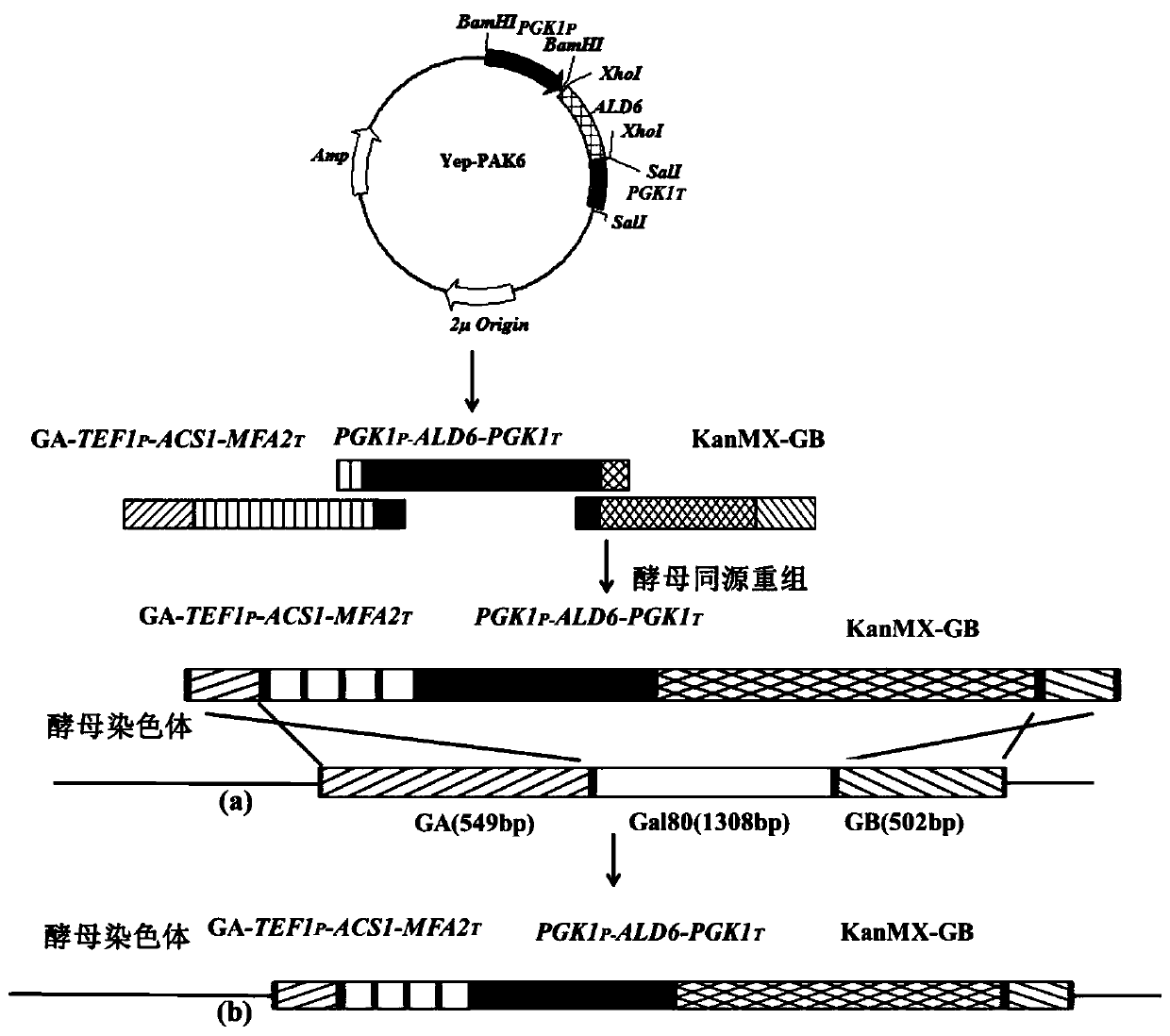

[0105] (1) Enhancing the synthesis of acetyl-CoA to produce C6-C10 ethyl ester Saccharomyces cerevisiae strain

[0106] Using the genome of yeast strain CA as a template and Gal80 as an integration site, PCR amplification with a primer pair of GA-U (SEQ ID NO:9) and GA-D (SEQ ID NO:10) yielded a 549bp TEF1 with a promoter P The upper homology arm GA segment of the homology region; use the primer pair GB-U (SEQ ID NO: 11) and GB-D (SEQ ID NO: 12) PCR amplification to obtain a size of 502bp with the screeni...

Embodiment 2

[0148] Embodiment 2: Corn mash fermentation experiment of producing C6-C10 ethyl ester Saccharomyces cerevisiae strain

[0149] 1) The specific fermentation process is: corn flour→soaking→liquefaction→saccharification→cooling→inoculation→fermentation→steaming wine→determining indicators;

[0150] 2) Process conditions

[0151] Soaking conditions: 60-70°C, soaking for 20 minutes; liquefaction conditions: 85-90°C, adding high-temperature-resistant α-amylase, liquefying for 90 minutes; saccharification conditions: 55-60°C, adding glucoamylase, saccharifying for 20 hours;

[0152] 3) Ingredients: 1500g corn flour, 4500mL water, let stand for 20min, high temperature resistant α-amylase 2×10 4 U / mL, 0.9ml, glucoamylase 1×10 5 U / mL, 3mL.

[0153] 4) Culture medium configuration

[0154] Primary seed medium: 8°Brix corn hydrolyzate, add 0.5% yeast extract powder, aliquot 5mL into test tubes, boil for 10min to sterilize.

[0155] Secondary seed medium: 12°Brix corn hydrolyzate, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com