A kind of catalyst carrier, precious metal catalyst and its preparation method and application

A precious metal catalyst, catalyst carrier technology, applied in catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve electrochemical corrosion, electrochemical corrosion of carbon materials and other problems, achieve strong electrochemical corrosion resistance, High conductivity and improved electrocatalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

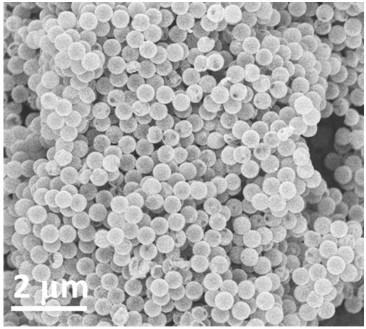

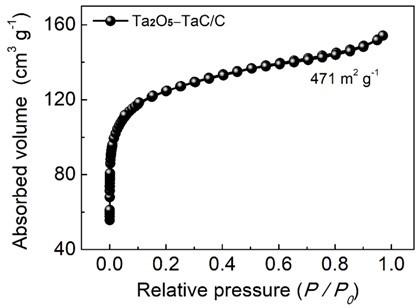

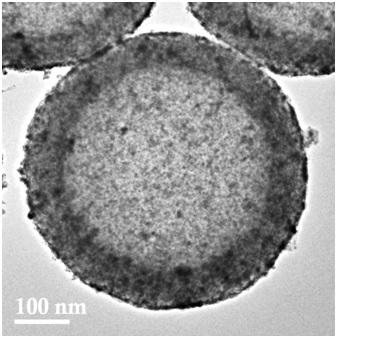

[0040]Preparation of tantalum pentoxide / tantalum carbide composite coated hollow carbon microsphere carrier supported platinum nanoparticle catalyst (Pt / Ta2O5-TaC / C), add a mixture of 12 mL of styrene monomer and 0.7 g of divinylbenzene crosslinker into a three-necked flask, add 130 mL of deionized water, and heat in an oil bath at 70°C and 350 rpm Stir while blowing in argon for 1 h to remove dissolved oxygen. Then, add 10 mL with a mass fraction of 0.005 g mL-1Potassium persulfate aqueous solution, and the mixture was heated at 70 ºC for 10 h under argon. After the solution is cooled, saturated sodium chloride is added to demulsify, the obtained monodisperse crosslinked polystyrene microspheres are collected by filtration, washed with deionized water, and then dried at 60°C. Disperse 3 g of cross-linked polystyrene microspheres in 100 mL of concentrated sulfuric acid solution and stir at 350 rpm at 40 ºC for 6 h. After cooling, the product was washed with deionized water until the...

Embodiment 2

[0045]The operating conditions were the same as in Example 1, except that the carbonization process was carried out. The temperature in the second heating process was 800 °C, and the tantalum pentoxide coated hollow carbon microsphere carrier supported platinum nanoparticle catalyst was prepared. The specific surface area of the hollow carbon microsphere carrier coated with tantalum pentoxide is 249.1 m2 g-1. The oxygen reduction polarization curve can be calculated, and the kinetic current density of the platinum catalyst based on this support under the condition of 0.9 V vs. RHE (Jk) 1.85 mA cm respectively-2,Platinum loading on the electrode surface (mpt ) Respectively 15 ug cm-2. Therefore, it can be calculated that the platinum catalyst based on this support has a mass activity of 0.123 A mg for oxygen reduction reaction at 0.9 V.–1Pt, Better than commercial platinum carbon catalyst. The sample was subjected to a potential cycle acceleration stability test, and the test condi...

Embodiment 3

[0047]The operating conditions are the same as those in Example 1, except for the carbonization process. The temperature in the second heating process is 1100 °C, and the tantalum carbide coated hollow carbon microsphere carrier is prepared to support the platinum nanoparticle catalyst. The specific surface area of the tantalum carbide coated hollow carbon microsphere carrier is 442.5 m2 g-1. The oxygen reduction polarization curve can be calculated, and the kinetic current density of the platinum catalyst based on the support under the condition of 0.9V vs. RHE (Jk) Respectively 2.31 mA cm-2,Platinum loading on the electrode surface (mpt ) Respectively 15 ug cm-2. Therefore, it can be calculated that the platinum catalyst based on this support has a mass activity of 0.154 A mg for oxygen reduction reaction at 0.9 V.–1Pt, Better than commercial platinum carbon catalyst. The sample was subjected to a potential cycle accelerated stability test under the same test conditions as in Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com