Organic polymer synthetic membrane based on antimony tailings and preparation method and application thereof

A technology of antimony tailings and polymers, which is applied in the direction of chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of complex production process and technology, weak anti-fouling ability, and difficult cleaning, and achieves the reduction of preparation cost and anti-corrosion Strong staining ability and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

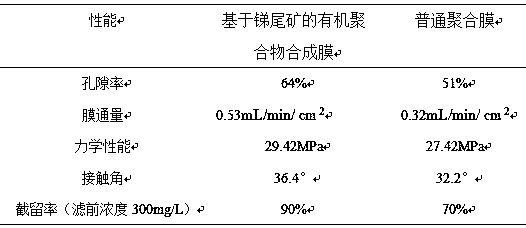

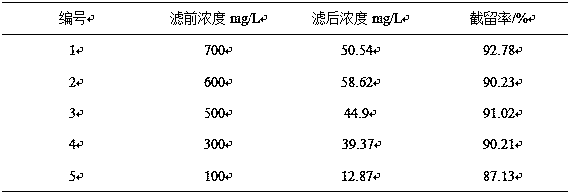

Examples

Embodiment 1

[0027] Example 1: The organic polymer synthetic film based on antimony tailings is made of the following components: N-methylpyrrolidone 76%, polyvinylidene fluoride 13%, glycerol 4.5%, polyethylene 4.5%, leaching 1% of antimony tailings after leaching agent and 1% of anhydrous lithium chloride; the antimony tailings after leaching agent leaching are the tailings produced after smelting the antimony ore in a sulfuric acid solution with a volume concentration of 10%. ℃, electric field strength 1V / m, stirring and leaching for 60 minutes, filtering, washing the filter residue with water until the pH of the washing liquid is 6, then drying and pulverizing to a particle size of less than 25μm. The solid-liquid ratio of antimony tailings and sulfuric acid is g:mL 1:10;

[0028] The preparation method of the above-mentioned antimony tailing-based organic polymer synthetic film is as follows:

[0029] (1) Mix N-methylpyrrolidone, polyvinylidene fluoride, polyethylene, glycerol, antimony t...

Embodiment 2

[0036] Example 2: The organic polymer synthetic film based on antimony tailings is made of the following composition: methyl acetate 72%, polystyrene 14%, ethylene glycol 4%, polyoxyethylene 4%, after leaching the leaching agent 5% of antimony tailings and 1% of anhydrous lithium chloride; the antimony tailings after leaching of the leaching agent are the tailings produced after smelting the antimony ore in a sulfuric acid solution with a volume concentration of 15%, at 40℃, electric field Stirring and leaching for 45 minutes at an intensity of 0.5V / m, filtering, washing the filter residue with water until the pH of the washing solution reaches 7, and then drying and pulverizing to a particle size of less than 25μm. The solid-to-liquid ratio of antimony tailings and sulfuric acid, g:mL, is 1: 12;

[0037] The preparation method of the above-mentioned antimony tailing-based organic polymer synthetic film is as follows:

[0038] (1) Mix methyl acetate, polystyrene, ethylene glycol, ...

Embodiment 3

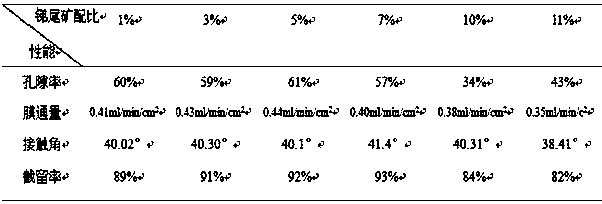

[0045] Example 3: The organic polymer synthetic film based on antimony tailings is made of the following composition:

[0046] 1. 76% of N-methylpyrrolidone, 13% of polyvinylidene fluoride, 4.5% of polyethylene, 4.5% of glycerol, 1% of antimony tailings after leaching with leaching agent, 1% of anhydrous lithium chloride;

[0047] 2. 75% methyl isobutyl ketone, 13% polyurethane, 4.5% polyethylene, 4.5% ethylene glycol, 3% antimony tailings after leaching agent, and 1% sodium bicarbonate;

[0048] 3. Acetonitrile 71%, polystyrene 14%, polyoxyethylene-polyoxypropylene copolymer 4.5%, acid phosphate amine salt 4.5%, antimony tailings 5% after leaching agent, PVA 1%;

[0049] 4. Methyl acetate 70%, polyacrylate 13%, polyethylene 4.5%, glycerol 4.5%, antimony tailings 7% after leaching agent, PEG 1%;

[0050] 5. Ethyl acetate 70%, polyvinylidene fluoride 11%, polyoxyethylene 4%, alkyl succinimide 4%, antimony tailings 10% after leaching agent, and urea 1%;

[0051] 6. Propyl acetate 70%, ethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com