Method of degrading printing and dyeing wastewater by activating persulfate with graphite-phase carbon nitride under dark reaction conditions

A technology of graphite phase carbon nitride and activated persulfate, which is applied in the direction of chemical instruments and methods, chemical/physical processes, nitrogen and non-metallic compounds, etc., can solve the problem of secondary pollution of metal activation, and achieve a stable removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Weigh 5 g of melamine and grind finely in a mortar to obtain powder A.

[0024] 2) Pour powder A into an alumina crucible, cover it and place it in a muffle furnace for 4h, heating rate 5℃ / min, calcination temperature 550℃, take out after the muffle furnace temperature drops to 80℃, get sample B.

[0025] 3) Transfer sample B into a mortar and grind to obtain a light yellow powder as graphite phase carbon nitride.

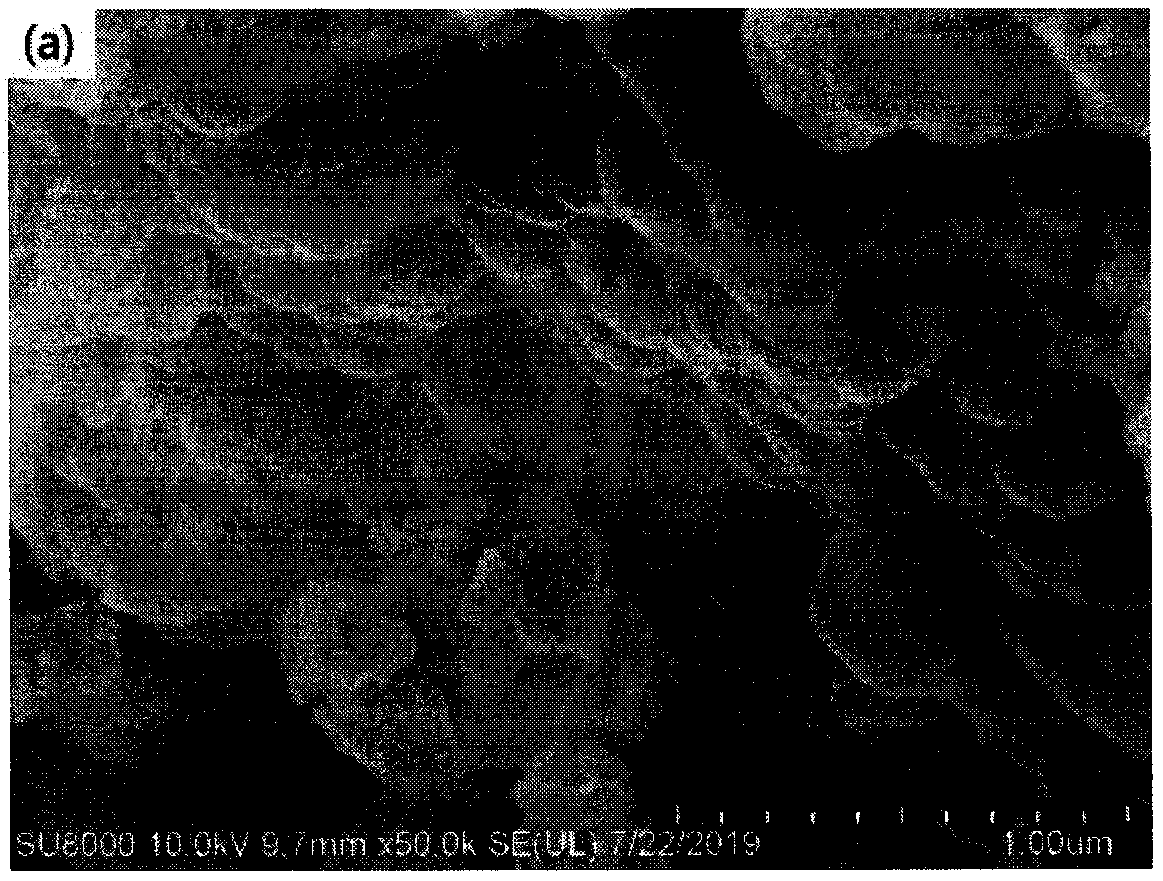

[0026] The scanning electron microscope image of the graphite phase carbon nitride material prepared above is as follows figure 1 As shown in the figure, it can be seen that the material has an irregular lamellar stacked structure, with uneven size distribution and a relatively smooth surface.

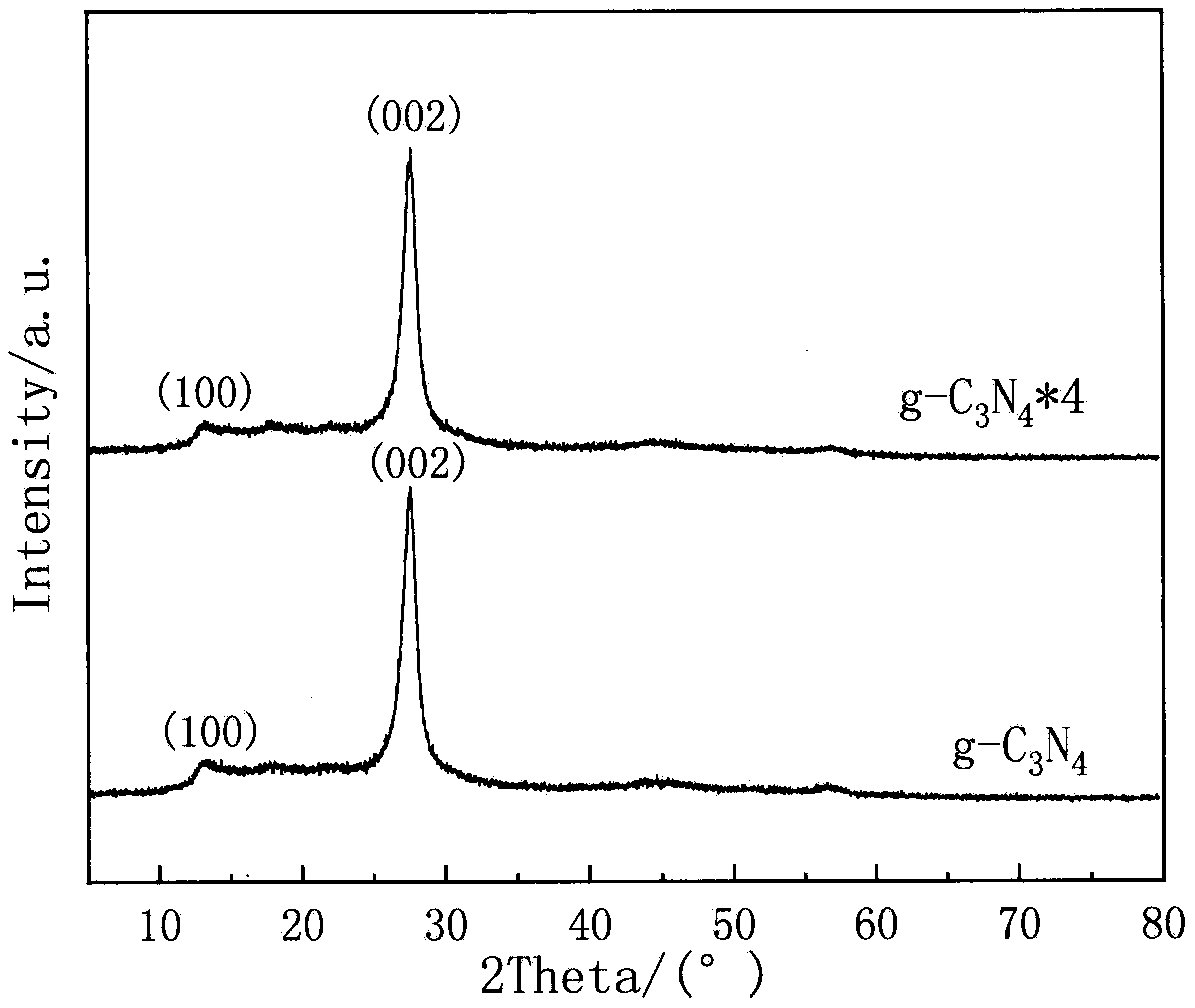

[0027] The X-ray diffractometer diagram of the graphite phase carbon nitride material prepared above is as follows figure 2 As shown, diffraction peaks appear at 2θ of 13.1° and 27.4°, corresponding to g-C 3 N 4 The (100) and (002) crystal planes indicate that the synthe...

Embodiment 2

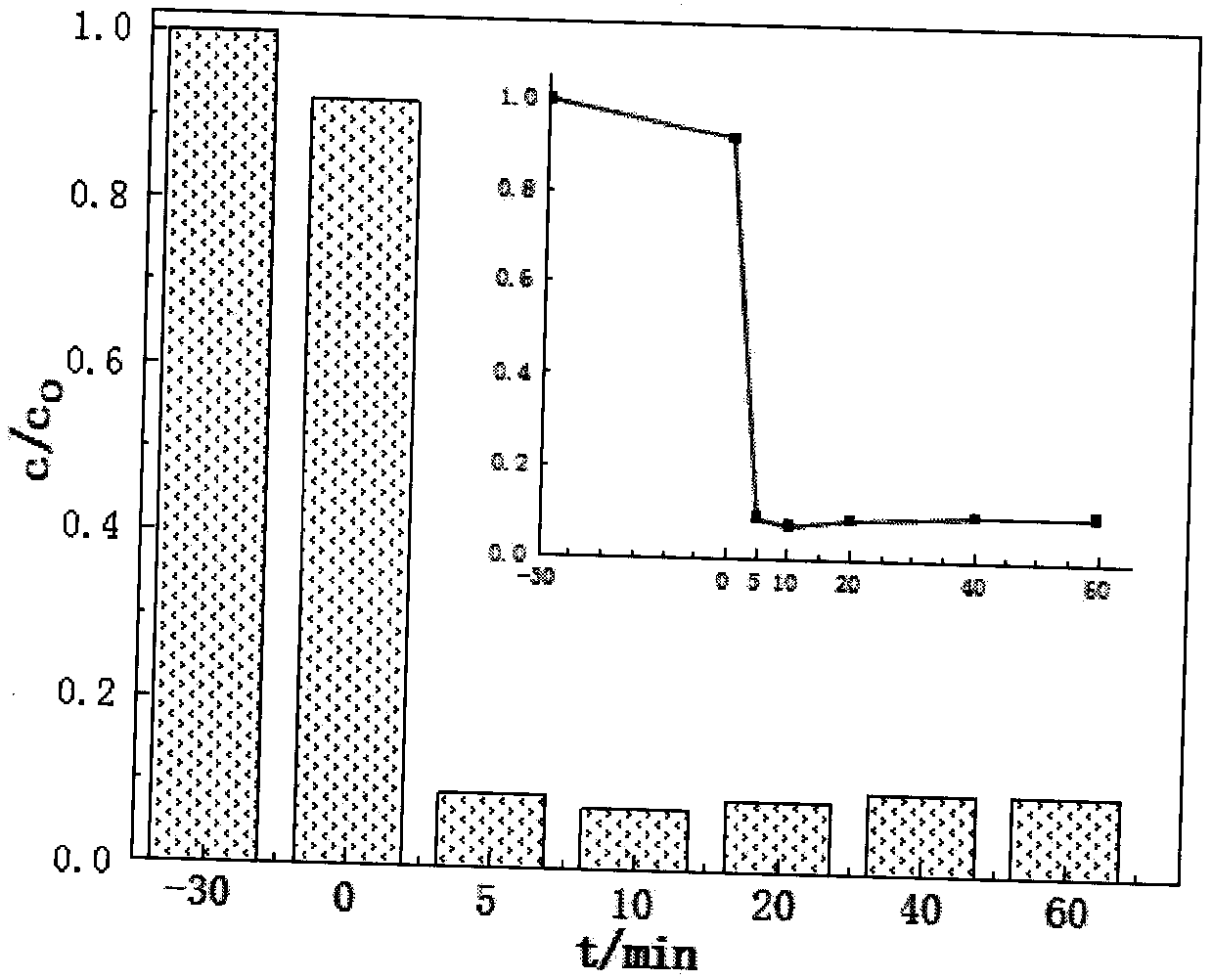

[0029] 1) Configure a 10 mg / L methylene blue solution as the target pollutant, measure 100 ml of the solution and a beaker, control the initial pH of the solution to 5, and the reaction temperature to 25°C, which is recorded as solution A.

[0030] 2) Under dark and shading conditions, add the graphite phase carbon nitride powder prepared in Example 1 to solution A, the dosage is 0.8g / L, and continue to stir for 30 minutes to achieve the adsorption-desorption of the catalyst and the target degradation product. With equilibrium, mixture B is obtained.

[0031] 3) Under dark and shading conditions, add sodium persulfate to the mixture B, the dosage is 5mg / L, start timing and continue to stir, and the reaction ends after 60 minutes.

[0032] The above experiment shows that the graphite phase carbon nitride activated sodium persulfate degrades the methylene blue of typical printing and dyeing wastewater under dark reaction conditions. image 3 .

[0033] The results show that the use of m...

Embodiment 3

[0035] Advantages of the present invention-stability and recycling test

[0036] Stability and recycling test

[0037] The present invention studies the stability and recycling properties of the catalyst in the experiment of degrading methylene blue by graphite phase carbon nitride activated persulfate under dark reaction conditions, and filters the graphite phase carbon nitride powder after participating in the reaction in specific implementation case 2. Collect, use ethanol and deionized water to alternately rinse and centrifuge to obtain clean powder, which is dried in an oven to obtain dry powder. Four cycles of experiments were carried out under the same experimental conditions, and the graphite phase carbon nitride powder (g-C 3 N 4 *4).

[0038] Graphite phase carbon nitride powder (g-C 3 N 4 *4) The scanning electron microscope picture is as follows Figure 4 As shown in the figure, it can be seen that the material is still in an irregular lamellar stacked structure, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com