Metallic nickel modified sulfur-indium-zinc photocatalyst and preparation method and application thereof

A technology of photocatalyst, sulfur indium zinc, which is applied in the preparation of photocatalytic materials and photocatalysis, can solve the problems of low sunlight utilization rate and low quantum efficiency, and achieve simple preparation method, simple production process, superior catalytic performance and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

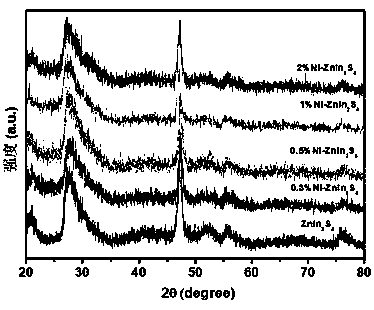

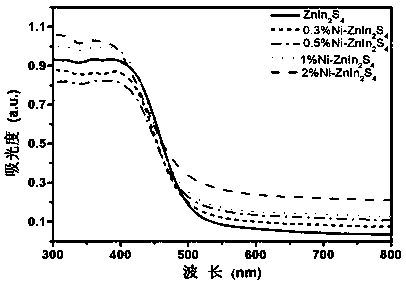

[0025] A Ni-ZnIn 2 S 4 The preparation method of composite photocatalyst comprises the following steps:

[0026] (1) Preparation of sulfur indium zinc ZnIn by hydrothermal method 2 S 4 nanomaterials:

[0027] Dissolve zinc nitrate hexahydrate, indium chloride tetrahydrate, and cetyltrimethylammonium bromide in deionized water, and stir magnetically at room temperature for 30 minutes; then add thioacetamide to the above solution; stir again After 30 min, the mixture was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and the autoclave was kept at 160 °C for 16 h; then, it was naturally cooled to room temperature to obtain a yellow solid; washed with absolute ethanol and deionized water to Residues were removed, and the final product was dried in a vacuum oven for 12 hours;

[0028] (2) Photodeposition method to prepare metal nickel-modified sulfur indium zinc Ni-ZnIn 2 S 4 Composite photocatalyst:

[0029] Ultrasonically disperse the sulfur ind...

Embodiment 1

[0039] Ni-ZnIn 2 S 4 Preparation of composite photocatalyst:

[0040] (1) ZnIn 2 S 4 The preparation is the same as Comparative Example 1;

[0041] (2) ZnIn 2 S 4 Ultrasonic dispersion into ethanol, adding nickel chloride solution, flowing nitrogen for 30 minutes, and irradiating with visible light with a wavelength greater than 420nm for 60 minutes. After washing with ethanol and drying in a vacuum oven, nickel-modified sulfur indium zinc (Ni-ZnIn 2 S 4 ) composite photocatalyst. (Ni and ZnIn 2 S 4 The mass ratio is 0.3%).

[0042] Photocatalytic hydrogen production coupling benzyl alcohol selective oxidation experiment:

[0043] Take 10.4 μL benzyl alcohol and 10 mL deionized water in the reactor, add 5 mg 0.3%Ni-ZnIn 2 S 4 Photocatalyst, placed under visible light (λ > 420 nm) for 5 hours under inert gas conditions, produced 21.8 μmol of hydrogen, 71.5 μmol of benzaldehyde, 89.6% conversion of benzyl alcohol, and 89.6% conversion of benzaldehyde The selectivi...

Embodiment 2

[0045] Ni-ZnIn 2 S 4 Preparation of composite photocatalyst:

[0046] (1) ZnIn 2 S 4 The preparation is the same as Comparative Example 1;

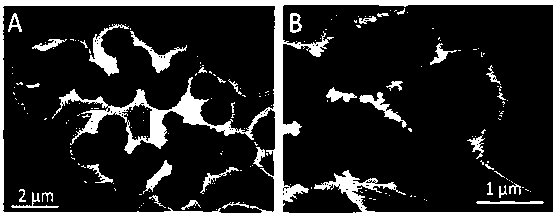

[0047] (2) ZnIn 2 S 4 Ultrasonic dispersion into ethanol, adding nickel chloride solution, flowing nitrogen for 30 minutes, and irradiating with visible light with a wavelength greater than 420nm for 60 minutes. After washing with ethanol and drying in a vacuum oven, nickel-modified sulfur indium zinc (Ni-ZnIn 2 S 4 ) composite photocatalyst. (Ni and ZnIn 2 S 4 The mass ratio is 0.5%). Its TEM picture is as follows figure 1 (B) shown.

[0048] Photocatalytic hydrogen production coupling benzyl alcohol selective oxidation experiment:

[0049] Take 10.4 μL benzyl alcohol and 10 mL deionized water in the reactor, add 5 mg 0.5%Ni-ZnIn 2 S 4 The photocatalyst was exposed to visible light (λ > 420 nm) for 5 hours under inert gas conditions, and the amount of hydrogen produced was 36.5 μmol, and the amount of benzaldehyde produce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com