A kind of positive electrode material and its preparation method and application

A cathode material, composite carbon technology, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problems of poor conductivity, wide band gap, low discharge specific capacity, etc., to improve stability, reduce usage, increase The effect of discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

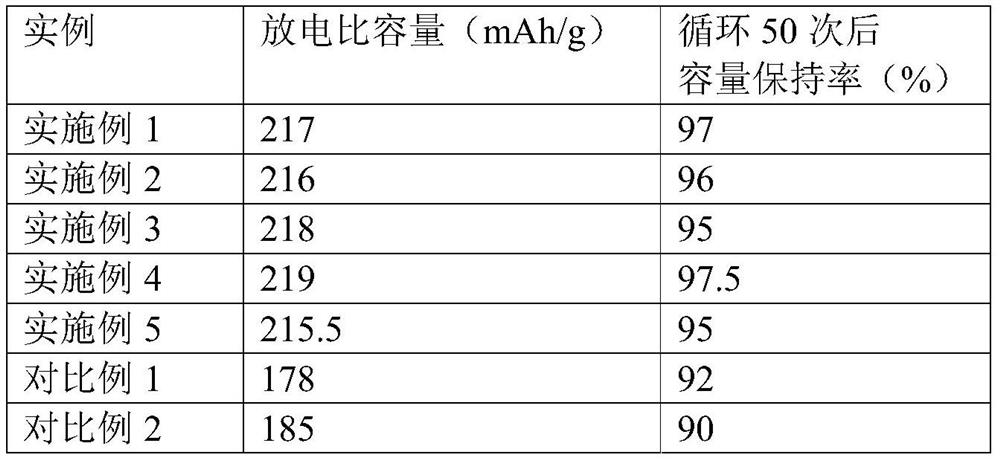

Examples

Embodiment 1

[0060] (1) Preparation of nitrogen, phosphorus, sulfur, chlorine in situ co-doped composite carbon materials

[0061] Weigh an appropriate amount of trimeric phosphazene chloride, pyrrole, thiourea, and hexachloro-1,3-butadiene so that the atomic ratio of nitrogen, phosphorus, sulfur, and chlorine is 1:1:3:0.1, and the above materials are mixed Finally, react at 180°C for 12h under high-pressure airtight conditions of 4MPa, cool the reacted product, wash with deionized water three times, and vacuum-dry at 90°C for 12h to obtain the first product. After high temperature treatment for 15 hours, nitrogen, phosphorus, sulfur and chlorine in-situ co-doped composite carbon materials were obtained.

[0062] (2) Preparation of nano titanium oxide sol

[0063] Add tetrabutyl titanate to absolute ethanol solution, and add diethanolamine dropwise while stirring. The molar ratio of tetrabutyl titanate to diethanolamine is 1:1. After fully stirring, add dropwise while stirring Adjust the...

Embodiment 2

[0067] (1) Preparation of nitrogen, phosphorus, sulfur, chlorine in situ co-doped composite carbon materials

[0068] Weigh an appropriate amount of trimeric phosphazene chloride, pyrrole, thiourea, and hexachloro-1,3-butadiene so that the atomic ratio of nitrogen, phosphorus, sulfur, and chlorine is 1:2:1:1, and the above materials are mixed Finally, react at 180°C for 12h under a high-pressure airtight condition of 4MPa, cool the reacted product, wash with deionized water three times, and vacuum-dry at 90°C for 12h to obtain the first product. After high temperature treatment for 4 hours, nitrogen, phosphorus, sulfur and chlorine in-situ co-doped composite carbon materials were obtained.

[0069] (2) Preparation of nano titanium oxide sol

[0070] Industrial grade titanium oxysulfate (TiOSO 4 ) dispersed in deionized water, configured into a titanyl sulfate aqueous solution with a mass concentration of 5%, adding an appropriate amount of concentrated sulfuric acid to adjus...

Embodiment 3

[0074] (1) Preparation of nitrogen, phosphorus, sulfur, chlorine in situ co-doped composite carbon materials

[0075] Weigh an appropriate amount of adenosine diphosphate, pyridine, mercaptan and hexachloro-1,3-butadiene so that the atomic ratio of nitrogen, phosphorus, sulfur and chlorine is 3:1:3:0.5, after the above materials are mixed, in React at 260°C for 2.5h under high-pressure airtight conditions of 3MPa, cool the reacted product, wash with deionized water 4 times, and vacuum-dry at 80°C for 16h to obtain the first product, which is treated at 1000°C in nitrogen After 1h, nitrogen, phosphorus, sulfur, and chlorine in-situ co-doped composite carbon materials were obtained.

[0076] (2) Preparation of nano titanium oxide sol

[0077] Industrial grade titanium oxysulfate (TiOSO 4 ) dispersed in deionized water, configured into an aqueous solution of titanyl sulfate with a mass concentration of 5%, adding an appropriate amount of concentrated sulfuric acid to adjust the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com