High-porosity foamed ceramic insulation board and preparation method thereof

A foamed ceramic and porosity technology, applied in the field of thermal insulation materials, can solve the problems of preparation technology, equipment, product quality gap, etc., and achieve the effects of excellent thermal insulation performance, easy dispersion, and reduced orderliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

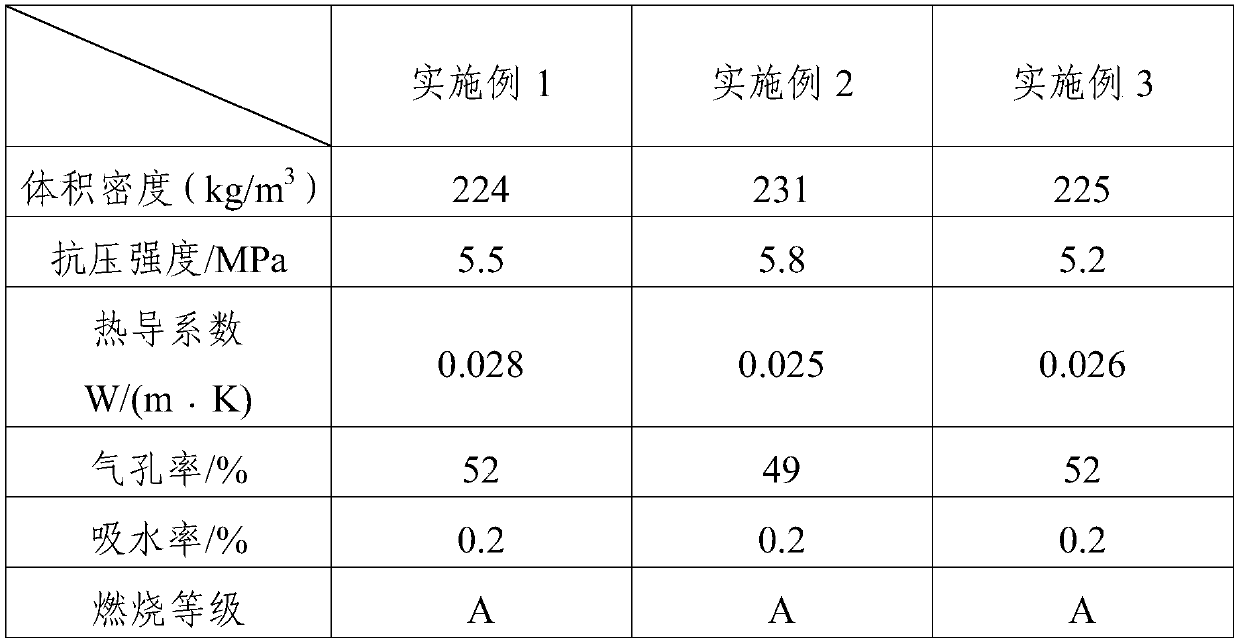

Examples

Embodiment 1

[0032] A high-porosity foamed ceramic insulation board is prepared from the following raw materials in parts by weight:

[0033] 120 parts of electrolytic manganese slag, 60 parts of red mud, 12 parts of basalt fiber, 14 parts of graphene, 25 parts of potassium albite feldspar, 8 parts of dolomite, 13 parts of chlorite, 20 parts of serpentine, 16 parts of coal gangue, 4 parts of alumina, 1 part of terbium oxide, 2 parts of antimony oxide, 3 parts of boric acid, 14 parts of bentonite, 5 parts of silicon carbide, 4 parts of fluorite, 40 parts of modified sodium bicarbonate, 3 parts of chitosan, hexametaphosphoric acid 10 parts of sodium, 15 parts of carboxymethyl cellulose, 6 parts of stabilizer composed of polyvinyl alcohol, polyacrylamide, and lauryl alcohol in a weight ratio of 5:1:1, and 350 parts of water.

[0034] The preparation method of modified sodium bicarbonate is as follows:

[0035] Dissolve citric acid in absolute ethanol, in a water bath at 35°C, under 300r / min ...

Embodiment 2

[0039] A high-porosity foamed ceramic insulation board is prepared from the following raw materials in parts by weight:

[0040] 100 parts of electrolytic manganese slag, 65 parts of red mud, 14 parts of basalt fiber, 15 parts of graphene, 20 parts of potassium albite feldspar, 8 parts of dolomite, 12 parts of chlorite, 20 parts of serpentine, 12 parts of coal gangue, 4 parts of alumina, 3 parts of terbium oxide, 2 parts of antimony oxide, 1 part of boric acid, 15 parts of bentonite, 2 parts of silicon carbide, 5 parts of fluorite, 40 parts of modified sodium bicarbonate, 3 parts of chitosan, hexametaphosphoric acid 10 parts of sodium, 18 parts of carboxymethyl cellulose, 10 parts of stabilizer composed of polyvinyl alcohol, polyacrylamide, and lauryl alcohol in a weight ratio of 4:2:1, and 400 parts of water.

[0041] The preparation method of modified sodium bicarbonate is as follows:

[0042] Dissolve citric acid in absolute ethanol, add sodium bicarbonate slowly under 40°...

Embodiment 3

[0046] A high-porosity foamed ceramic insulation board is prepared from the following raw materials in parts by weight:

[0047] 100 parts of electrolytic manganese slag, 70 parts of red mud, 12 parts of basalt fiber, 20 parts of graphene, 20 parts of potassium albite feldspar, 6 parts of dolomite, 10 parts of chlorite, 12 parts of serpentine, 12 parts of coal gangue, 5 parts of alumina, 1 part of terbium oxide, 3 parts of antimony oxide, 2 parts of boric acid, 12 parts of bentonite, 3 parts of silicon carbide, 5 parts of fluorite, 30 parts of modified sodium bicarbonate, 4 parts of chitosan, hexametaphosphoric acid 8 parts of sodium, 15 parts of carboxymethyl cellulose, 10 parts of a stabilizer composed of polyvinyl alcohol, polyacrylamide, and lauryl alcohol in a weight ratio of 4:1:1, and 350 parts of water.

[0048] The preparation method of modified sodium bicarbonate is as follows:

[0049] Dissolve citric acid in absolute ethanol, in a water bath at 35°C, under 300r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com