A kind of preparation method and application of cobalt phosphate modified carbon fiber composite electrode material

A composite electrode and electrode material technology, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., can solve the problems of restricting the production and application of oxygen evolution electrocatalysts, increasing the difficulty of electrode preparation, and the content of impurities that are easy to agglomerate, so as to improve electrocatalysis. Controllable oxygen performance, growth rate and particle size, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

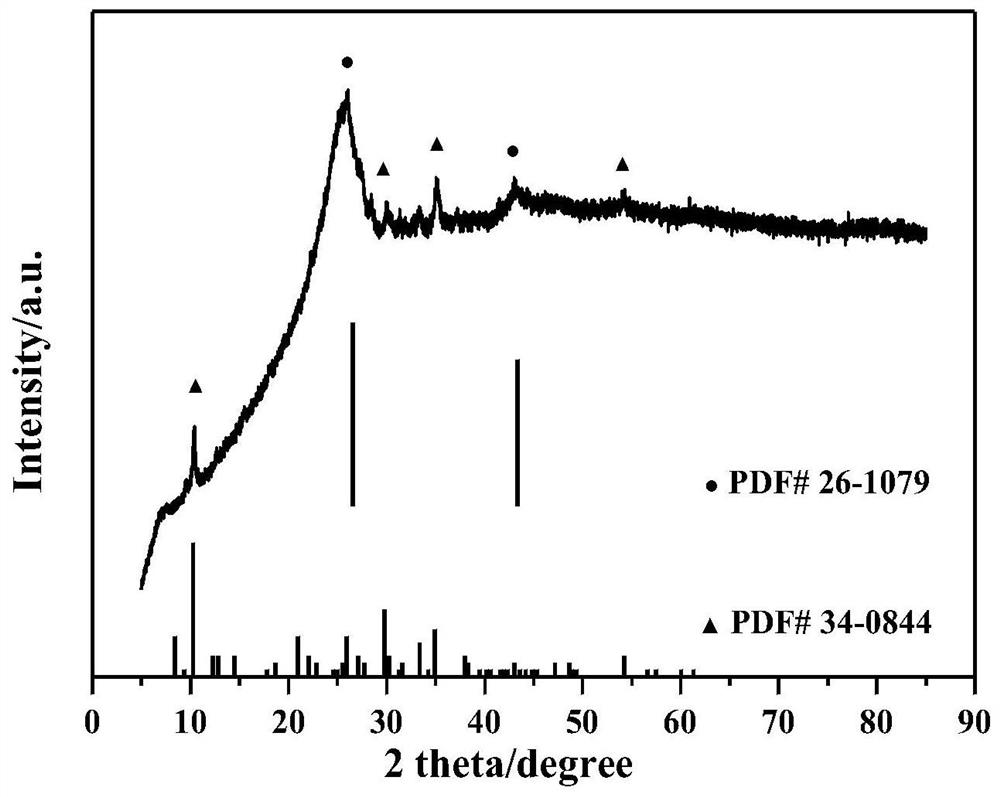

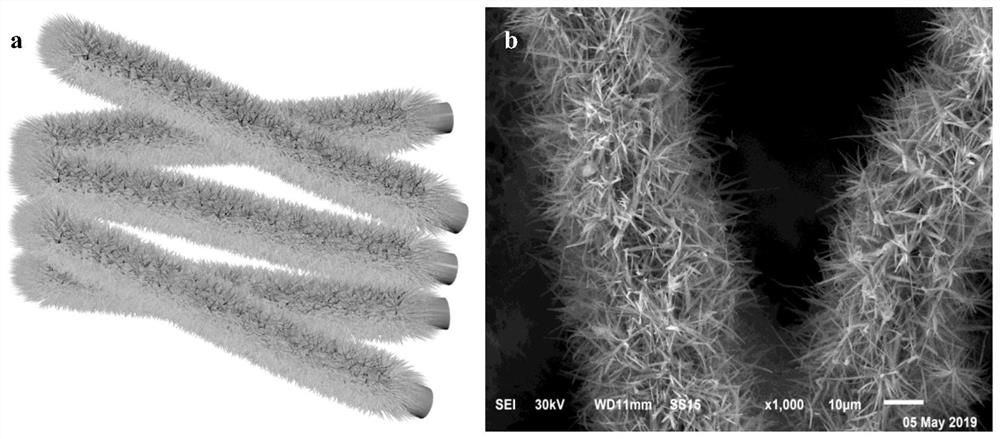

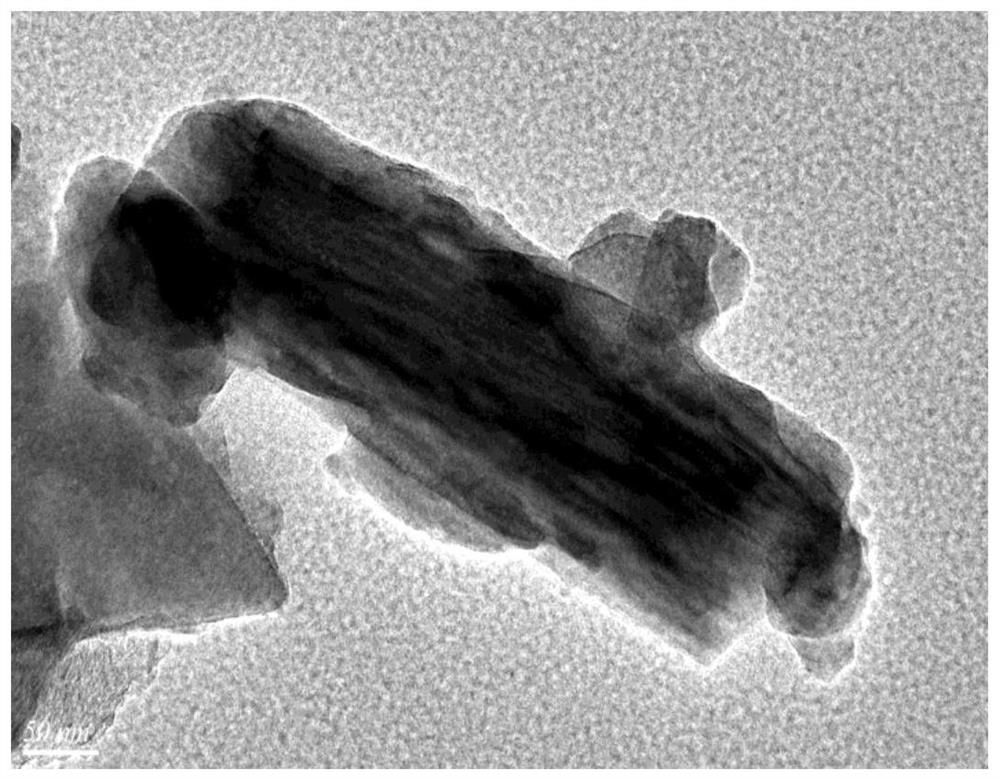

Method used

Image

Examples

Embodiment 1

[0035] Cut a polyacrylonitrile carbon felt with a length of 10 cm, a width of 10 cm, and a thickness of 0.5 cm, and then ultrasonically clean it in acetone, ethanol, and deionized water, and then dry it; immerse the polyacrylonitrile carbon felt in concentrated nitric acid, and conduct a hydrothermal reaction at 70°C for 24 hours. Acid treatment;

[0036] Take the polyacrylonitrile carbon felt (PAN) acidified by concentrated acid into the inner lining of the reactor; use deionized water as a solvent, dissolve 4mol / L urea as a hydrolysis agent, add 0.1mol / L ammonium fluoride as a growth-directing agent, and magnetically Add 2mol / L cobalt ion salt under stirring. After mixing evenly, transfer it to the lining of the reactor to immerse the carbon felt, and keep it at 70°C for hydrothermal reaction for 24 hours; after cooling, wash the polyacrylonitrile carbon felt with deionized water, and dry it at 70°C overnight to obtain a cobalt hydroxide-modified carbon fiber composite mater...

Embodiment 2

[0039] Cut a polyacrylonitrile carbon felt with a length of 12cm, a width of 14cm, and a thickness of 0.8cm, and then ultrasonically clean it in acetone, ethanol, and deionized water, and then dry it; take concentrated nitric acid and immerse the polyacrylonitrile carbon felt, and conduct a hydrothermal reaction at 120°C for 7 hours. Acid treatment;

[0040] Take the polyacrylonitrile carbon felt (PAN) acidified by concentrated acid into the inner lining of the reactor; use deionized water as solvent, dissolve 6mol / L urea as hydrolyzing agent, add 0.5mol / L ammonium fluoride as growth directing agent, and magnetically Add 3mol / L cobalt ion salt under stirring. After mixing evenly, transfer it to the lining of the reactor to immerse the carbon felt, and keep it at 120°C for hydrothermal reaction for 7 hours; after cooling, wash the polyacrylonitrile carbon felt with deionized water, and dry it at 70°C overnight to obtain a cobalt hydroxide modified carbon fiber composite material;...

Embodiment 3

[0046] Cut an activated carbon felt with a length of 15 cm, a width of 15 cm, and a thickness of 1 cm, and then ultrasonically clean it in acetone, ethanol, and deionized water, and then dry it; take concentrated nitric acid and immerse the activated carbon felt, and conduct a hydrothermal reaction at 160°C for 4 hours to perform acidification;

[0047] Take the activated carbon felt acidified by concentrated acid into the lining of the reactor; use deionized water as solvent, dissolve 4mol / L urea as hydrolyzing agent, add 0.1mol / L ammonium fluoride as growth-directing agent, add 2mol / L under magnetic stirring Cobalt ion salt. After mixing evenly, transfer it to the lining of the reaction kettle to immerse the carbon felt, and keep it at 160°C for hydrothermal reaction for 4 hours; after cooling, wash the activated carbon felt with deionized water, and dry it at 70°C overnight to obtain a cobalt hydroxide-modified carbon fiber composite material;

[0048] Diammonium hydrogen p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com