Vanadium dioxide and two-dimensional semiconductor junction type photodetector and preparation method thereof

A two-dimensional semiconductor, vanadium dioxide technology, applied in the field of nanomaterials, can solve the problems of limited absorption, difficult to extend, difficult to suppress, etc., to achieve the effect of reducing self-resistance, changing current size, and high-sensitivity photodetection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

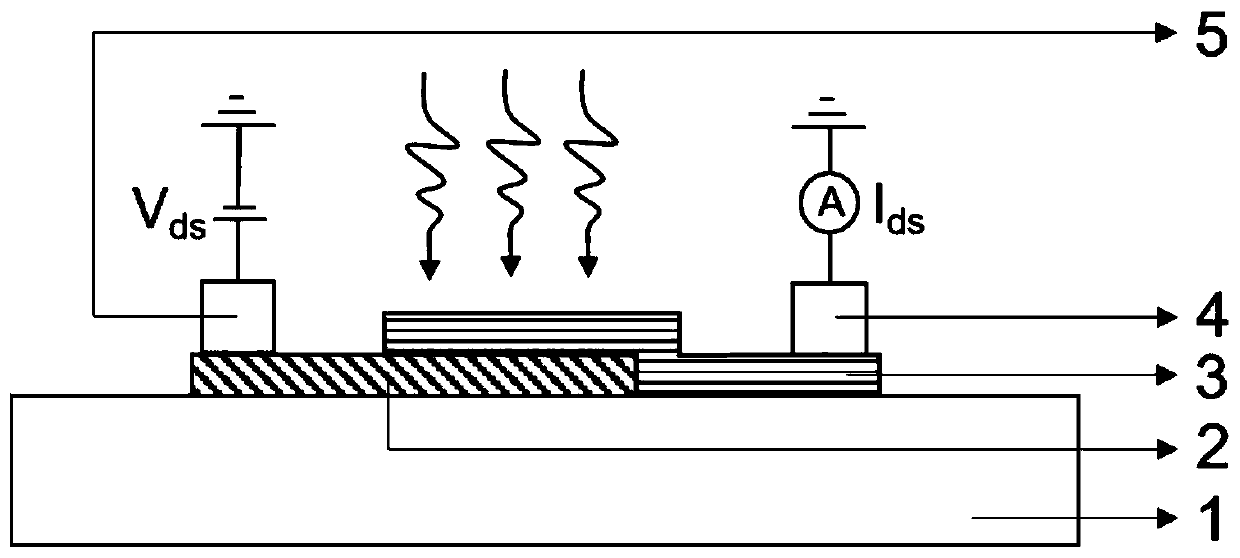

[0023] 1) A uniform vanadium metal film is sputtered on an alumina substrate by magnetron sputtering, and transformed into a vanadium dioxide film by thermal oxidation, with a film thickness of 22 nanometers and a surface roughness of 1 nanometer ;

[0024] 2) using ultraviolet lithography to make an array mask on the vanadium dioxide film in step 1, using argon plasma etching technology to etch away the exposure area, and forming a square array of vanadium dioxide after removing the mask;

[0025] 3) The two-dimensional semiconductor molybdenum ditelluride is peeled off on the silicon wafer by a mechanical peeling method, with a thickness of 20 nanometers. Use polydimethylsiloxane (PDMS) to transfer the exfoliated two-dimensional semiconductor to the surface of vanadium dioxide in step 2, and then remove PDMS to form a vertical heterojunction structure of two-dimensional semiconductor material and vanadium dioxide dislocation stacking .

[0026] 4) Using ultraviolet lithogr...

Embodiment 2

[0028] 1) A uniform vanadium metal film is sputtered on an alumina substrate by magnetron sputtering, and transformed into a vanadium dioxide film by thermal oxidation, with a film thickness of 22 nanometers and a surface roughness of 1 nanometer ;

[0029] 2) using ultraviolet lithography to make an array mask on the vanadium dioxide film in step 1, using argon plasma etching technology to etch away the exposure area, and forming a square array of vanadium dioxide after removing the mask;

[0030] 3) The two-dimensional semiconductor molybdenum ditelluride is peeled off on the silicon wafer by a mechanical peeling method, with a thickness of 30 nanometers. Use polydimethylsiloxane (PDMS) to transfer the exfoliated two-dimensional semiconductor to the surface of vanadium dioxide in step 2, and then remove PDMS to form a vertical heterojunction structure of two-dimensional semiconductor material and vanadium dioxide dislocation stacking .

[0031] 4) Using ultraviolet lithogr...

Embodiment 3

[0033] 1) A uniform vanadium metal film is sputtered on an alumina substrate by magnetron sputtering, and transformed into a vanadium dioxide film by thermal oxidation, with a film thickness of 22 nanometers and a surface roughness of 1 nanometer ;

[0034] 2) using ultraviolet lithography to make an array mask on the vanadium dioxide film in step 1, using argon plasma etching technology to etch away the exposure area, and forming a square array of vanadium dioxide after removing the mask;

[0035] 3) The two-dimensional semiconductor molybdenum ditelluride is peeled off on the silicon wafer by a mechanical peeling method, with a thickness of 40 nanometers. Use polydimethylsiloxane (PDMS) to transfer the exfoliated two-dimensional semiconductor to the surface of vanadium dioxide in step 2, and then remove PDMS to form a vertical heterojunction structure of two-dimensional semiconductor material and vanadium dioxide dislocation stacking .

[0036] 4) Using ultraviolet lithogr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com