Method for preparing boron-doped carbon nanospheres from lignin, and product

A technology of carbon nanospheres and lignin, which is applied in the direction of nano-carbon, can solve the problems of large water consumption, easy blockage of feeding devices, and low coke utilization value, so as to achieve effective utilization, inhibit agglomeration, and avoid low drying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

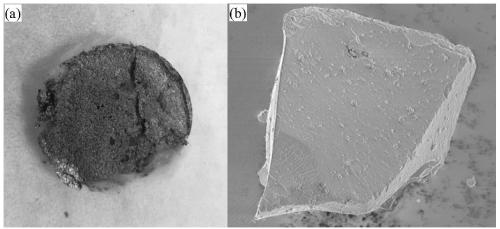

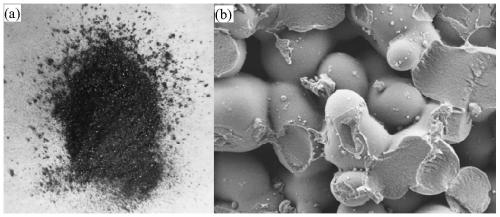

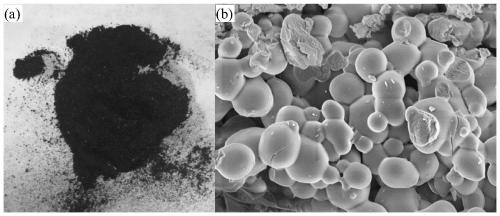

Image

Examples

Embodiment 1

[0043] S1 mix and dissolve boric acid and lignin in water in a preset ratio to obtain a mixed solution, wherein the mass ratio of boric acid to lignin is 1:50, and the mass of lignin added per milliliter of water is 0.1g;

[0044] S2 performs ultrasonic treatment on the mixed solution to hydrolyze the boric acid to generate tetrahydroxyborate ions, and to uniformly disperse the tetrahydroxyborate ions on the surface of the lignin. A crosslinking reaction occurs to obtain a pretreated lignin solution, wherein the power of the ultrasonic treatment is 60W, the frequency is 60 Hz, and the ultrasonic treatment time is 10 minutes;

[0045] S3 performs drying and grinding treatment on the pretreated lignin solution, the drying temperature is 65°C, the drying time is 48 hours, and the particle size is 120 mesh, and the pretreated lignin powder with anti-caking function is obtained;

[0046] S4 The treated lignin powder was calcined at 400°C for 20 minutes in an inert atmosphere, and t...

Embodiment 2

[0051] S1 Mix and dissolve potassium tetraborate and lignin in water in a set ratio to obtain a mixed solution, wherein the mass ratio of potassium tetraborate to lignin is 1:20, and the quality of lignin added per milliliter of water is 0.05g;

[0052] S2 performs ultrasonic treatment on the mixed solution, so that potassium tetraborate is hydrolyzed to generate tetrahydroxy borate ions, and the tetrahydroxy borate ions are evenly dispersed on the surface of lignin, and the tetrahydroxy borate ions are combined with the lignin surface. Hydroxyl functional groups undergo a crosslinking reaction to obtain a pretreated lignin solution, wherein the power of the ultrasonic treatment is 80W, the frequency is 50 Hz, and the ultrasonic treatment time is 20 minutes;

[0053] S3 performs drying and grinding treatment on the pretreated lignin solution, the drying temperature is 105°C, the drying time is 24 hours, and the particle size is 100 mesh, and the pretreated lignin powder with an...

Embodiment 3

[0060] S1 Mix and dissolve sodium tetraborate and lignin in water in a certain proportion to obtain a mixed solution, wherein the mass ratio of sodium tetraborate to lignin is 1:10, and the quality of lignin added per milliliter of water is 0.01g;

[0061] S2 performs ultrasonic treatment on the mixed solution, so that sodium tetraborate is hydrolyzed to generate tetrahydroxy borate ions, and the tetrahydroxy borate ions are evenly dispersed on the surface of lignin, and the tetrahydroxy borate ions are combined with the lignin surface. Hydroxyl functional groups undergo a crosslinking reaction to obtain a pretreated lignin solution, wherein the power of the ultrasonic treatment is 100W, the frequency is 40 Hz, and the ultrasonic treatment time is 30 minutes;

[0062] S3 performs drying and grinding treatment on the pretreated lignin solution, the drying temperature is 90°C, the drying time is 30 hours, and the particle size is 80 mesh, and the pretreated lignin powder with ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com