Preparation method of graphene modified polyether-ether-ketone composite material

A graphene modification, polyetheretherketone technology, applied in the field of composite materials, can solve the problems of large loss, high energy consumption, low preparation efficiency, etc., and achieve the effects of reducing loss, saving energy, and improving thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the graphene modified polyether ether ketone composite material of this embodiment includes the following steps:

[0027] Step 1: Weigh each component, weigh in parts by weight and control the properties of each component to meet:

[0028] 100 parts of polyether ether ketone, polyether ether ketone is injection molding grade polyether ether ketone, melt index is 10g / 10min, injection molding grade polyether ether ketone has more excellent mechanical properties and friction and wear resistance;

[0029] 1 part of single-walled carbon nanotubes, carbon nanotubes have good mechanical strength and can effectively increase the mechanical strength of materials;

[0030] Carbon fiber is 5 parts and the aspect ratio is 5:1. Compared with conventional graphite fiber, carbon fiber has better high temperature resistance, friction resistance, electrical conductivity, heat conduction and corrosion resistance, which further increases the high temperature resistance an...

Embodiment 2

[0043] This embodiment is basically the same as embodiment 1, but the difference is that the components in step one are weighed in parts by weight as follows:

[0044] 100 parts of polyether ether ketone, polyether ether ketone is injection molding grade polyether ether ketone, melt index is 50g / 10min;

[0045] 5 parts of multi-walled carbon nanotubes;

[0046] 5 parts of carbon fiber, length to diameter ratio of 10:1;

[0047] 10 parts of graphene, the oxygen content of the graphene is 10%, and the thickness of the graphene sheet is 0.5-5nm;

[0048] 5 parts of cubic boron nitride;

[0049] The coupling agent is 3 parts, and the coupling agent is KH570.

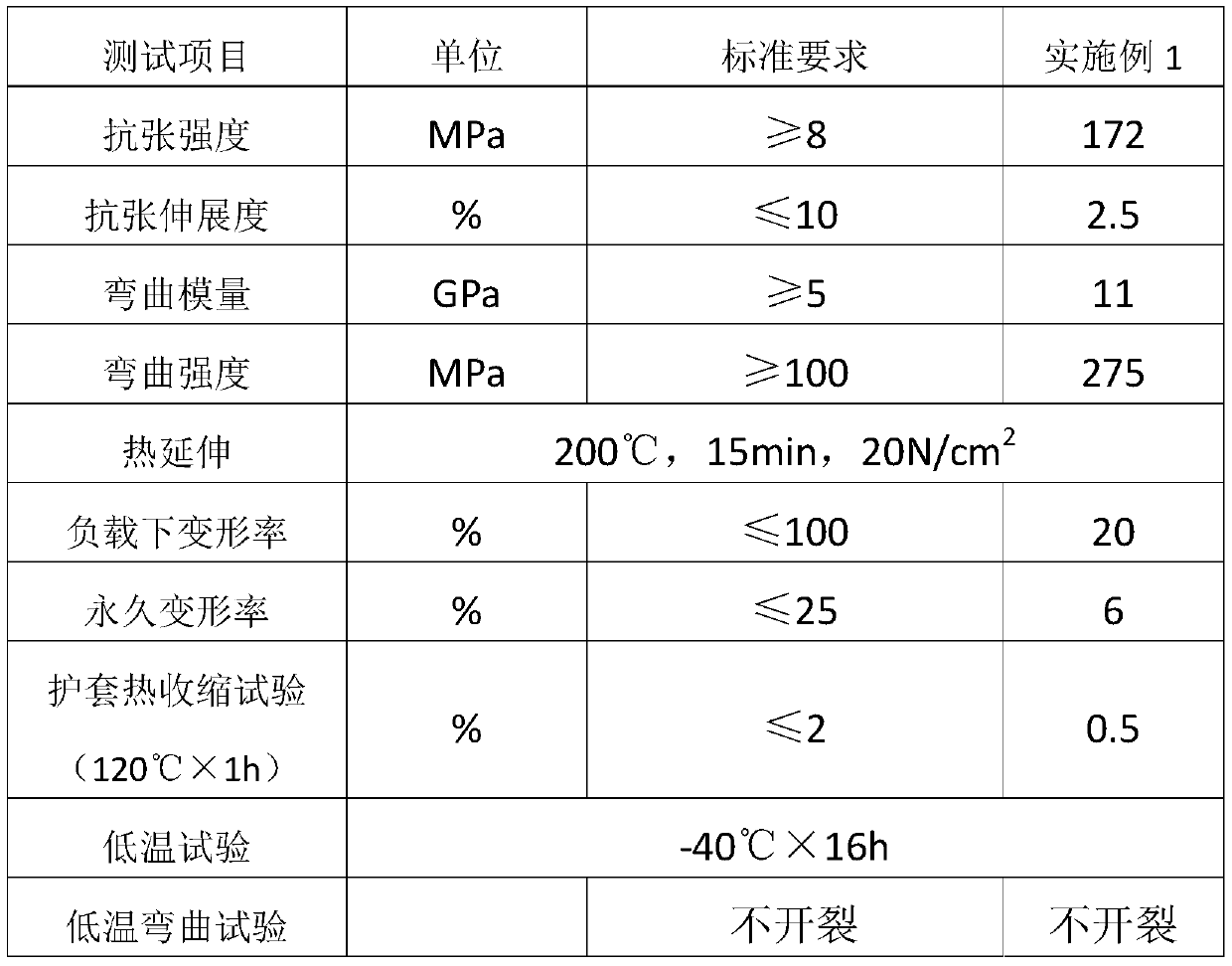

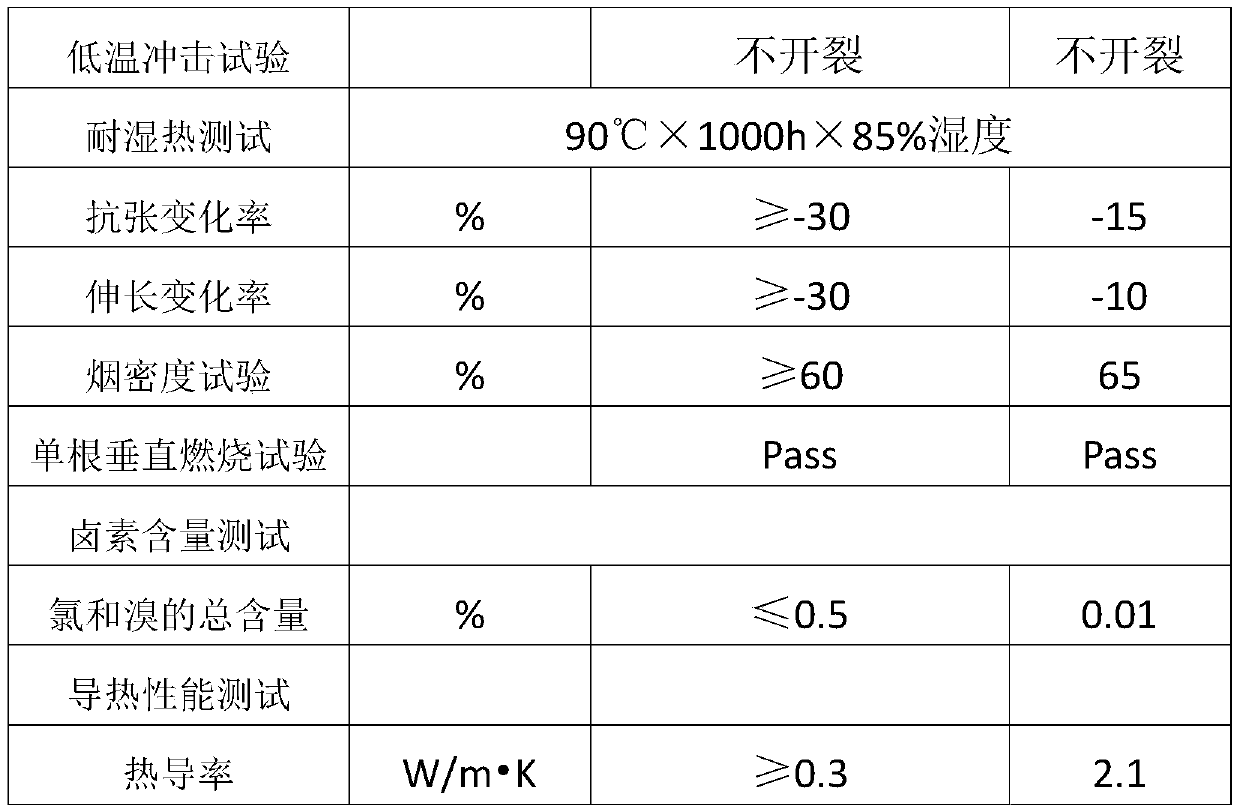

[0050] The graphene modified polyether ether ketone composite material prepared by the method of this embodiment was tested for performance, and the results are shown in Table 2:

[0051]

[0052]

[0053] Table 2

Embodiment 3

[0055] This embodiment is basically the same as embodiment 1, but the difference is that the components in step one are weighed in parts by weight:

[0056] 100 parts of polyether ether ketone, polyether ether ketone is injection molding grade polyether ether ketone, melt index is 30g / 10min;

[0057] 3 copies of multi-walled carbon nanotubes;

[0058] 2 parts of carbon fiber, the aspect ratio of carbon fiber is 7:1;

[0059] 7 parts of graphene, the oxygen content of the graphene is 1-10wt%, and the thickness of the graphene sheet is 0.5-5nm;

[0060] 2 parts of hexagonal boron nitride;

[0061] The coupling agent is 2 parts, and the coupling agent is isopropyl triisostearoyl titanate.

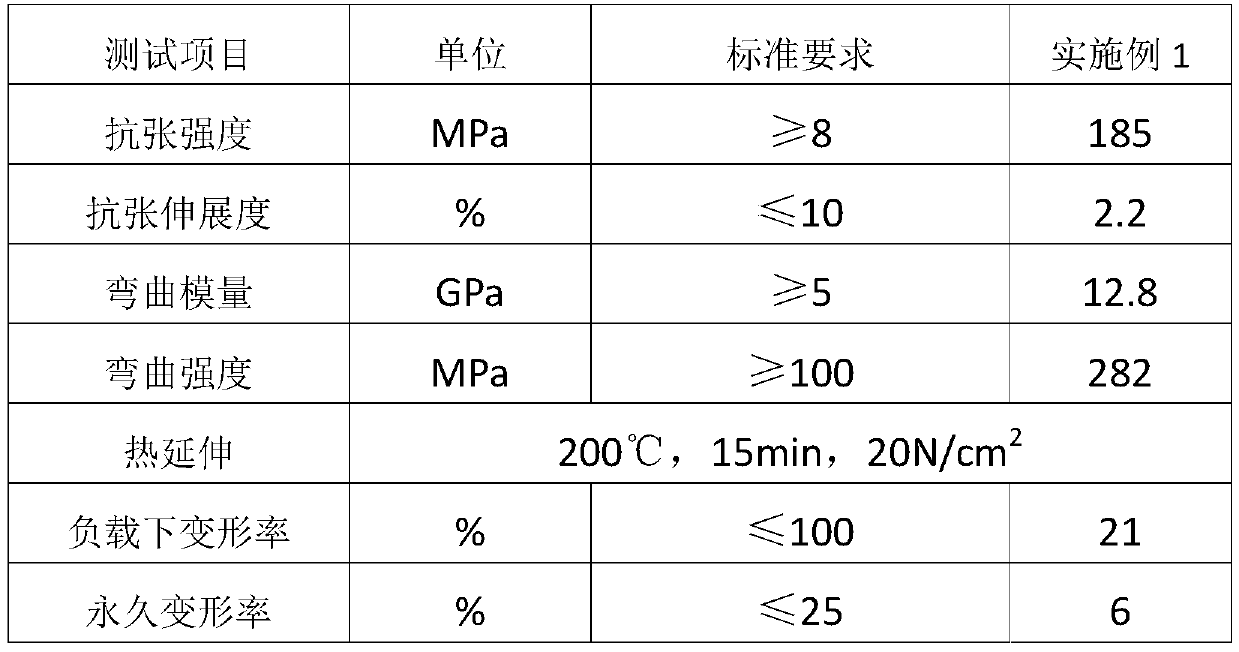

[0062] The graphene modified polyether ether ketone composite material prepared by the method of this embodiment was tested for performance, and the results are shown in Table 3:

[0063]

[0064]

[0065] table 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com