Moisturizing antibacterial soap and preparation method thereof

An antibacterial soap and soap-based technology, applied in the field of daily chemical cleaning products, can solve the problems of soap allergy, soap dissolution loss, dry skin, etc., and achieve obvious synergistic gain effect, good antibacterial effect, and improved antibacterial effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

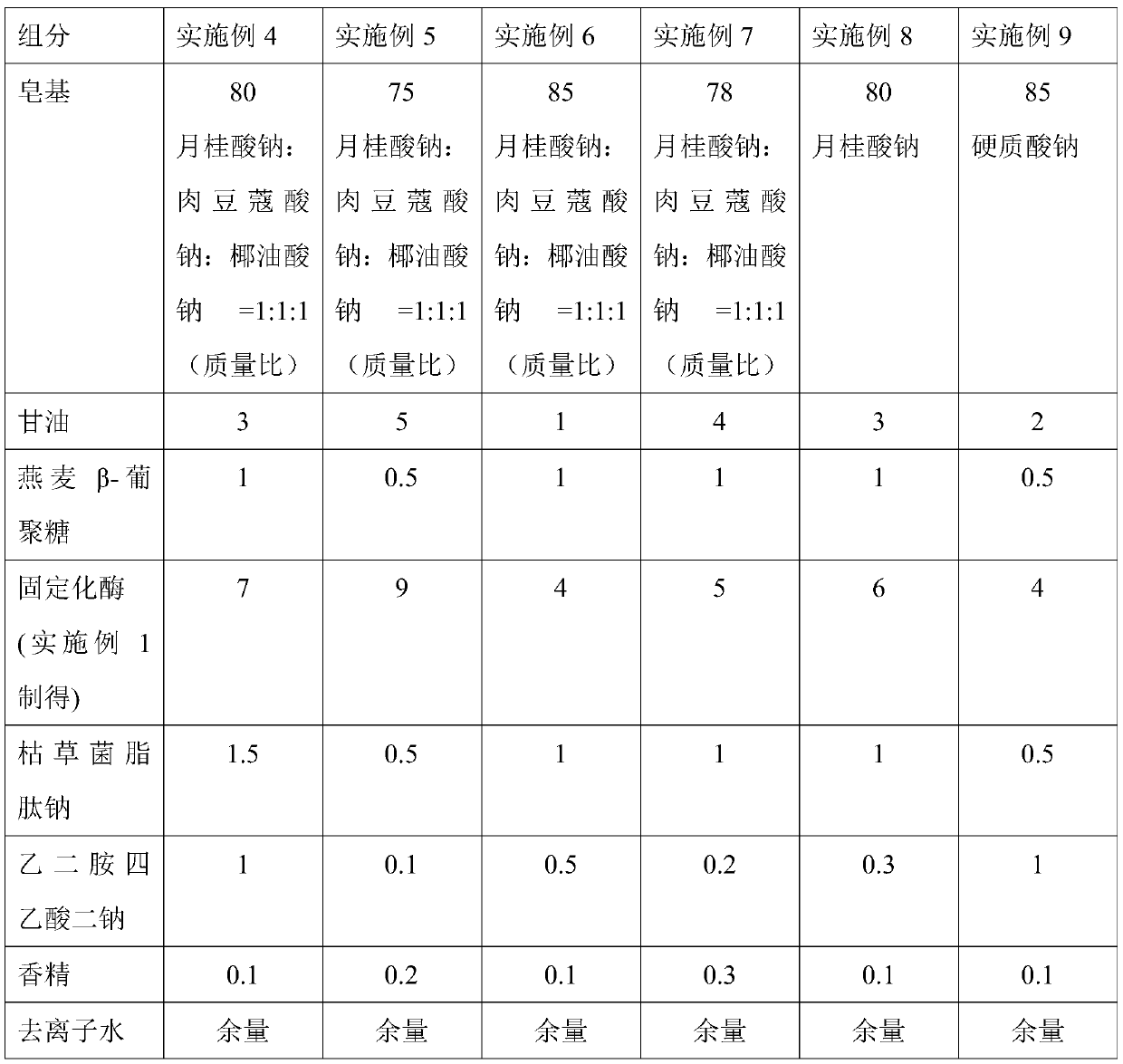

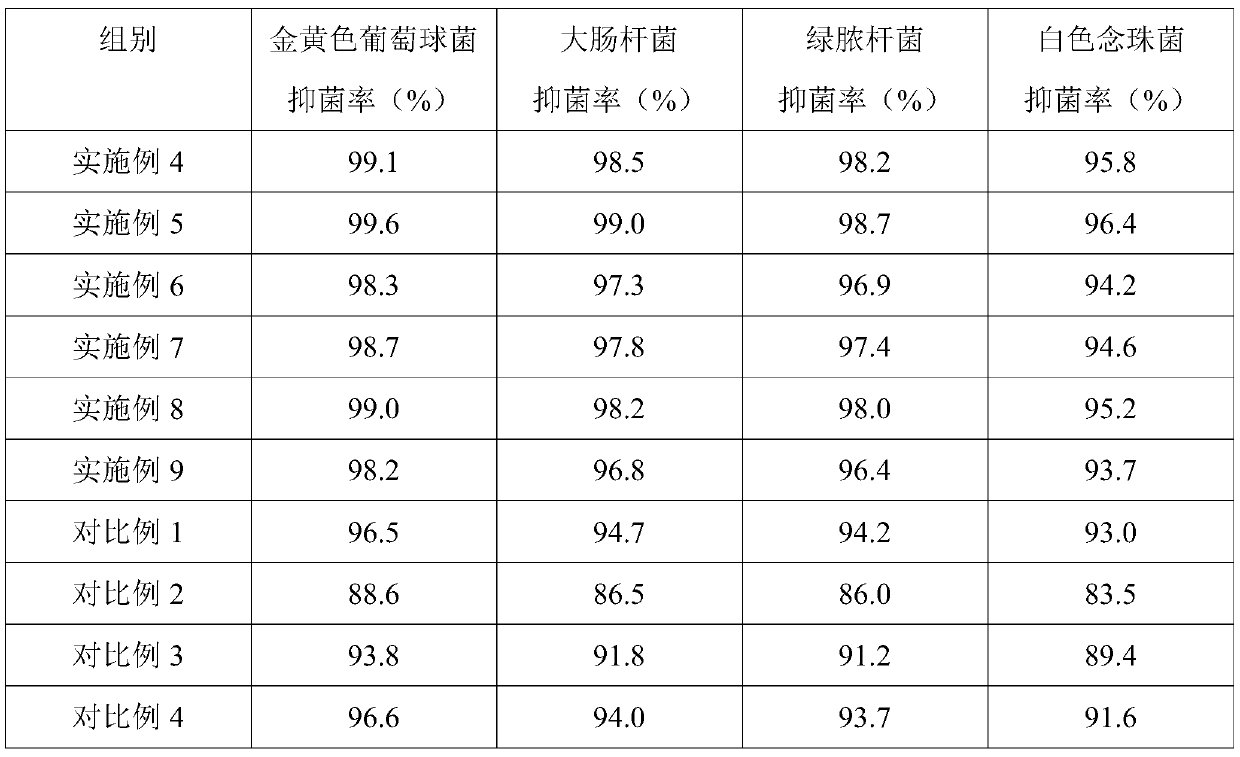

Examples

Embodiment 1

[0032] The preparation of the immobilized enzyme of this embodiment comprises the following steps:

[0033] (1) Take by weighing 100mg chitosan and be dissolved in the acetic acid solution of 2wt%, make its concentration be 1mg / mL, obtain chitosan solution;

[0034] (2) take by weighing 10mg shellac acid and be dissolved in ethanol, make the shellac acid solution that concentration is 0.4mg / mL;

[0035] (3) Weigh 5 mg of lysozyme and dissolve it in deionized water to obtain an enzyme solution with a total protein concentration of 0.5 mg / mL;

[0036] (4) Mix chitosan solution and shellac acid solution, stir magnetically at room temperature for 10 minutes, then add enzyme solution, continue to stir for 10 minutes, add genipin in a ratio of 1 wt% by final concentration, and continue to stir until the system becomes a gel shape, add an appropriate amount of sodium carbonate solution dropwise, adjust the pH value to 6, solidify at room temperature for 30 minutes, and dry in vacuum...

Embodiment 2

[0038] The preparation of the immobilized enzyme of this embodiment comprises the following steps:

[0039] (1) take by weighing 100mg chitosan and be dissolved in the acetic acid solution of 10wt%, make its concentration be 2mg / mL, obtain chitosan solution;

[0040] (2) take by weighing 25mg shellac acid and be dissolved in ethanol, make the shellac acid solution that concentration is 1mg / mL;

[0041] (3) Weigh 10 mg of lysozyme and dissolve it in deionized water to obtain an enzyme solution with a total protein concentration of 0.1 mg / mL;

[0042](4) Mix chitosan solution and shellac acid solution, stir magnetically at room temperature for 20 minutes, then add enzyme solution, continue to stir for 5 minutes, add genipin in a ratio of 2 wt% by final concentration, and continue to stir until the system becomes a gel shape, add an appropriate amount of sodium carbonate solution dropwise, adjust the pH value to 7, solidify at room temperature for 25 minutes, and dry in vacuum a...

Embodiment 3

[0044] The preparation of the immobilized enzyme of this embodiment comprises the following steps:

[0045] (1) Take by weighing 100mg chitosan and be dissolved in the acetic acid solution of 0.5wt%, make its concentration be 1mg / mL, obtain chitosan solution;

[0046] (2) take by weighing 15mg shellac acid and be dissolved in ethanol, make the shellac acid solution that concentration is 0.5mg / mL;

[0047] (3) Weigh 1 mg of lysozyme and dissolve it in deionized water to obtain an enzyme solution with a total protein concentration of 0.1 mg / mL;

[0048] (4) Mix chitosan solution and shellac acid solution, stir magnetically at room temperature for 15 minutes, then add enzyme solution, continue to stir for 10 minutes, add genipin in a ratio of 3 wt% by final concentration, continue to stir until the system is gel shape, add an appropriate amount of sodium carbonate solution dropwise, adjust the pH value to 5.5, solidify at room temperature for 30 minutes, and dry in vacuum at low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com