Nanometer needle-shaped cobalt-nickel sulfide/carbon paper flexible electrode and preparation method thereof

A technology of cobalt-nickel sulfide and flexible electrodes, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems affecting the energy density and power density of supercapacitors, and the complexity of high-cost preparation processes. Energy density and cycle stability, the effect of improving cycle stability and energy density, and enriching storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A kind of preparation method of nano needle cobalt nickel sulfide / carbon paper flexible electrode, comprises the following steps,

[0044] Step 1, facial tissue pretreatment,

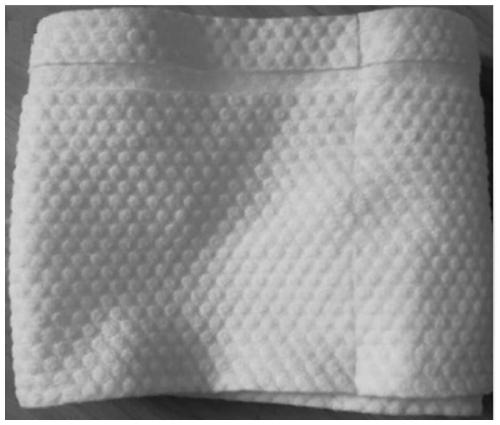

[0045] Clean the facial tissue and dry it. The present invention adopts the disposable cotton soft cleansing tissue whose brand is Cotton Wing as an example. Its main raw material is high-quality spunlace non-woven fabric; 10) After the small pieces of cm×(2~10)cm are ultrasonically cleaned with acetone and absolute ethanol or methanol in sequence;

[0046] Step 2, electrode substrate preparation,

[0047] Wash and dry the tissue paper in an inert gas such as argon, or N 2 Under the protection of the environment, carry out high-temperature carbonization treatment at 700-1000°C, and keep it warm for 0.5-3 hours. This can increase the content of carbon fibers and stabilize the fiber strength. The carbonization process is heated from room temperature, and the heating rate is 1-10°C / min , can impr...

Embodiment 1

[0053] The first step, facial tissue pretreatment,

[0054] After cutting facial tissues into small pieces of 2cm×2cm, ultrasonically clean them sequentially with acetone and absolute ethanol, repeat three times, and place them in a drying oven to dry for later use;

[0055] In the second step, electrode substrate preparation,

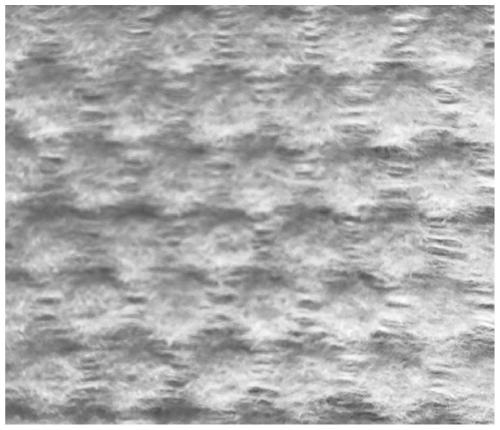

[0056] Place the dried face tissue in a tube furnace under an argon atmosphere at a heating rate of 3°C / min, raise the temperature to 800°C, keep it at 800°C for 1 hour, and cool down to room temperature naturally with the furnace, and the obtained carbon paper is placed in dry box spare;

[0057] The third step, electrode preparation,

[0058] Configuration 0.0375mol / L nickel nitrate hexahydrate, 0.075mol / L cobalt nitrate hexahydrate, 0.135mol / L urea and 0.015mol / L cetyltrimethylammonium bromide mixed solution 80mL, the second step obtained Put the carbon paper in it, transfer it to the reaction kettle, and react at 120°C for 3 hours. After the rea...

Embodiment 2

[0060] The first step, facial tissue pretreatment,

[0061] Cut facial tissues into small pieces of 3cm×3cm, then ultrasonically clean them with acetone and absolute ethanol in sequence, repeat three times, and place them in a drying oven to dry for later use;

[0062] In the second step, electrode substrate preparation,

[0063] Place the dried face tissue in a small vacuum tube furnace under an argon atmosphere at a heating rate of 3°C / min, raise the temperature to 900°C, keep it at 900°C for 1 hour, cool down to room temperature naturally with the furnace, take it out and place it in a dry place. box spare;

[0064] The third step, electrode preparation,

[0065] Configuration 0.0375mol / L nickel nitrate hexahydrate, 0.075mol / L cobalt nitrate hexahydrate, 0.135mol / L urea and 0.015mol / L cetyltrimethylammonium bromide mixed solution 80mL, the second step obtained Put the carbon paper in it, transfer it to the reaction kettle, and react at 120°C for 3 hours. After the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com