Halogen anion intercalated hydrotalcite positive electrode material, preparation method thereof and halogen anion battery

A technology of anion intercalation and positive electrode materials, applied in the field of electrochemistry, can solve the problems of small volume specific capacity of chloride ion batteries, small particle size of hydrotalcite nanosheet materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a method for preparing a halogen anion intercalation hydrotalcite positive electrode material, comprising the following steps:

[0040] Mix the first soluble metal salt, the second soluble metal salt, cyclohexamethylenetetramine and water to obtain a reaction solution; the metal ion M in the first soluble metal salt 1 Including Co 2+ 、Ni 2+ , Mg 2+ , Fe 2+ or Zn 2+; The metal ion M in the second soluble metal salt 2 Including Co 2+ , Fe 2+ , Fe 3+ 、Ti 3+ , Mn 3+ , V 3+ 、Al 3+ or Co 3+ ;

[0041] Under a protective atmosphere, the reaction solution is subjected to a co-precipitation reaction to obtain a precursor;

[0042] Mixing the precursor, liquid bromine and a nitrile solvent, performing a topological redox reaction, to obtain a bromide ion-intercalated hydrotalcite nanosheet material;

[0043] mixing the bromide ion-intercalated hydrotalcite nanosheet material with an aqueous solution of sodium fluoride, and performing a first ...

Embodiment 1

[0098] (1) Preparation of bromide ion intercalated hydrotalcite nanosheet material

[0099] NiCl 2 ·6H 2 O, CoCl 2 ·6H 2 O and cyclohexamethylenetetramine are dissolved in deionized water to obtain a reaction solution, in which NiCl 2 ·6H 2 The concentration of O is 0.005mol / L, CoCl 2 ·6H 2 The concentration of O is 0.01mol / L, and the concentration of hexamethylenetetramine is 0.4mol / L;

[0100] Under the protection of nitrogen, the reaction solution was reacted at 100°C for 8 hours and then centrifuged, the obtained solid was washed 3 times with water, and vacuum-dried at room temperature and vacuum degree of 0.1MPa for 24 hours to obtain Co 2 Ni(OH) 6 Precursor;

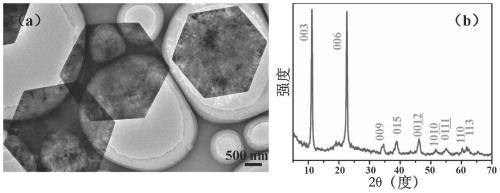

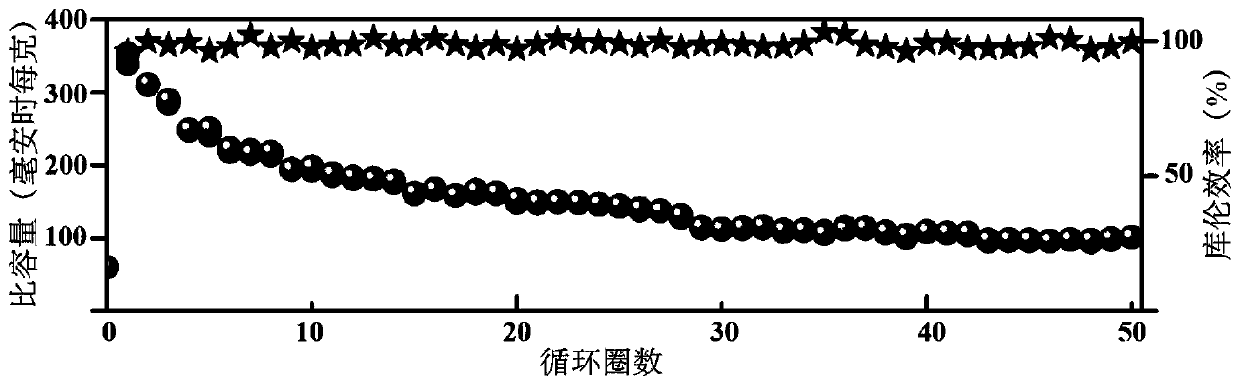

[0101] 0.2g Co 2 Ni(OH) 6 Disperse the precursor into 100mL of acetonitrile, add 0.5mol liquid bromine, react at room temperature and 1500rpm for 24 hours, then centrifuge, wash the resulting solid with absolute ethanol to remove excess liquid bromine, and dry it at room temperature for 24 hours to obtai...

Embodiment 2

[0109] (1) Preparation of fluoride ion intercalated hydrotalcite nanosheet material

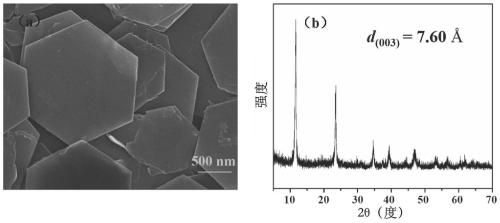

[0110] Sodium fluoride was dissolved in CO-free 2 In deionized water, a sodium fluoride solution with a concentration of 2mol / L was prepared; at room temperature and 1500rpm, after CoNi-BrLDH and sodium fluoride solution prepared in Example 1 were reacted for 24h, centrifuged, the resulting solid was used Wash with deionized water until neutral, and dry at 60°C for 24 hours to obtain fluoride ion-intercalated hydrotalcite nanosheet material (abbreviated as CoNi-F LDH).

[0111] (2) Preparation of fluoride ion intercalated hydrotalcite nanosheet cathode material

[0112] Stir and mix polyvinylidene fluoride and N-methylpyrrolidone (mass ratio = 5:95) for more than 10 hours until the white polyvinylidene fluoride powder is dissolved in N-methylpyrrolidone to obtain a polyvinylidene fluoride solution;

[0113] Grind and mix CoNi-F LDH (40mg), acetylene black and polyvinylidene fluoride solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com