Mixed fiber composite phase change temperature control material and preparation method thereof

A technology of phase change temperature control and mixed fiber, which is applied in the field of materials, can solve the problems of high cost and affecting the repeated use of crystalline hydrated salt phase change materials, and achieve the effects of reducing dosage, ensuring cycle stability, and reducing supercooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 3.5 g of starch into 100 mL of purified water, and stir it for 60 min with an overhead stirrer at a speed of 300 r / min to obtain a uniform and viscous starch solution, which is divided into two parts for later use.

[0035] Take 30g of bagasse pulp and 7g of crushed glass fiber wool and slowly add to one of the starch solutions under stirring, then stir at 40°C and 200r / min for 90min to obtain a suspension with uniformly dispersed fibers.

[0036] Then, add 40g of sodium sulfate decahydrate, 12g of ammonium chloride, 5g of borax and 2.5g of chloramine into another starch solution, and stir for 60min at 40°C and 500r / min to obtain a homogeneous solution.

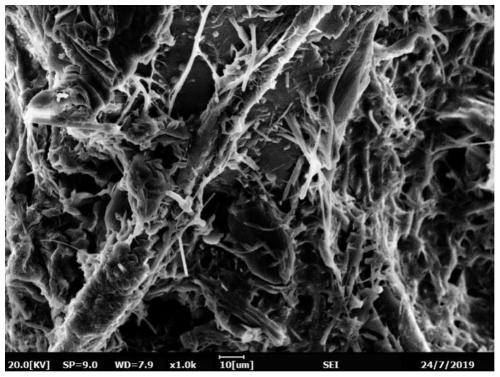

[0037] Finally, the above two solutions were mixed together, and stirred at a speed of 300 r / min for 120 min at 40° C. and 150 W ultrasonic conditions to obtain a phase-change temperature-controlling material composited with mixed fibers. The scanning electron microscope photograph of the sample is as figure 1As s...

Embodiment 2

[0039] Add 6 g of polyvinylpyrrolidone into 100 mL of purified water, and stir it for 60 min at a speed of 500 r / min with an overhead stirrer to obtain a uniform viscous solution, which is divided into two parts for later use.

[0040] Take 35g of waste paper pulp and 8g of crushed rock wool and slowly add it to the polyvinylpyrrolidone solution under stirring, then stir for 90min at 35°C and 200r / min to obtain a suspension with uniformly dispersed fibers.

[0041] Then, add 35g of sodium sulfate decahydrate, 8g of potassium chloride, 6g of barium hydroxide octahydrate and 2g of copper sulfate into another polyvinylpyrrolidone solution, and stir for 60min at 35°C and 500r / min to obtain a homogeneous solution .

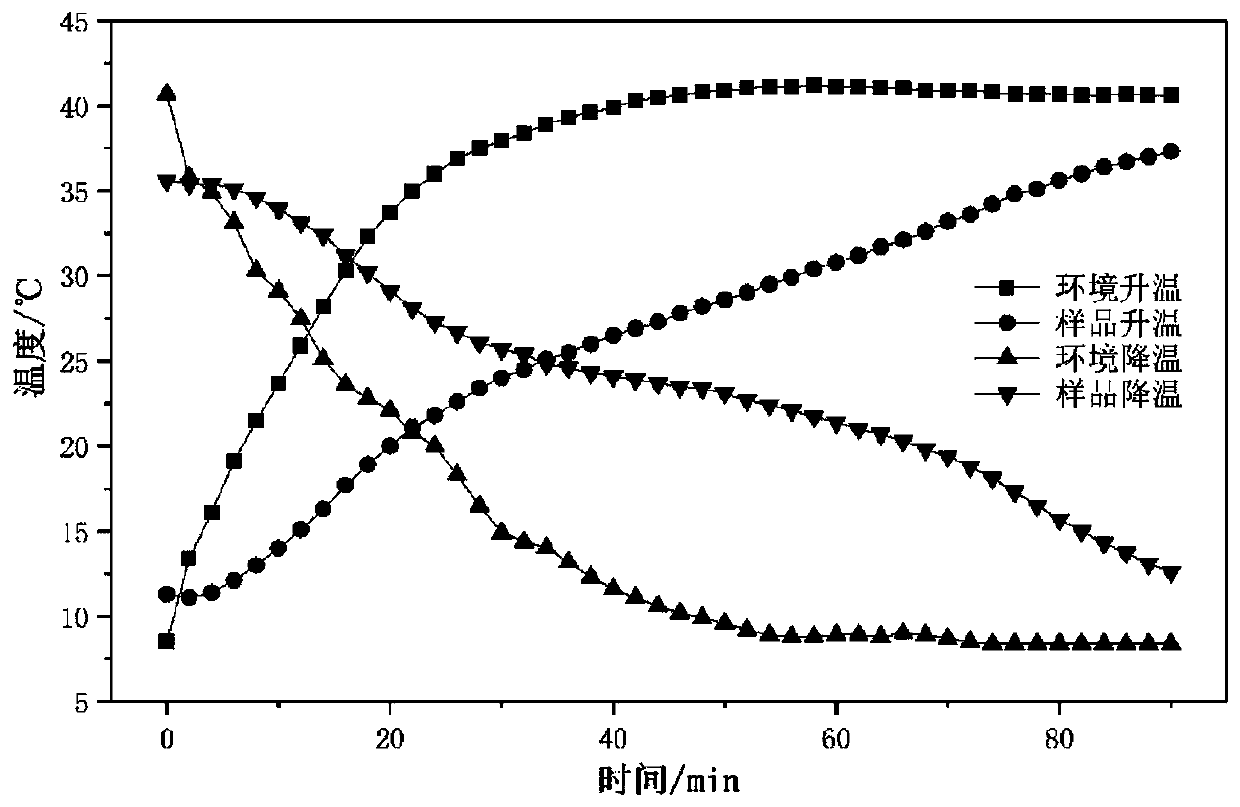

[0042] Finally, the above two solutions were mixed together, and stirred at a speed of 500 r / min for 180 min at 35° C. and 200 W ultrasonic conditions to obtain a mixed fiber composite phase change temperature control material. The temperature change of the sample wit...

Embodiment 3

[0044] Add 2 g of polyethylene oxide-polypropylene oxide block copolymer into 100 mL of pure water, and stir it for 60 min at a speed of 200 r / min with an overhead stirrer to obtain a uniform viscous solution, which is divided into two backup.

[0045] Take 25g of waste paper pulp and 10g of crushed rock wool and slowly add it to the block copolymer solution under stirring, then stir at 50°C and 200r / min for 90min to obtain a suspension with uniformly dispersed fibers.

[0046] Then, take 50g of calcium chloride hexahydrate, 4g of magnesium chloride hexahydrate, 8g of nano-silicon dioxide and 1g of isothiazolinone, add another part to the block copolymer solution, and stir for 60min at 50°C and 600r / min , to obtain a homogeneous solution.

[0047] Finally, the above two solutions were mixed together, and stirred at a speed of 400 r / min for 180 min at 50° C. and 100 W ultrasonic conditions to obtain a phase-change temperature-controlling material composited with mixed fibers. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase change enthalpy | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com