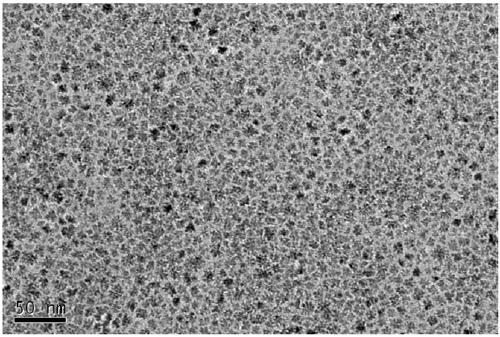

Oil-soluble monodisperse nano cerium dioxide catalyst as well as preparation method and application thereof

A nano-ceria, monodisperse technology, used in molecular sieve catalysts, ceria/ceria hydroxide, physical/chemical process catalysts, etc., can solve the problems of low sedimentation rate, incomplete stable dispersion, low particle solid content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] As another aspect of the present invention, a kind of preparation method of oil-soluble monodisperse nano ceria catalyst of the present invention comprises the steps:

[0065] 1) taking a mixture of an organic solvent and water as a solvent, adding a cerium salt and a doped metal salt to it to prepare a salt solution;

[0066] 2) taking a mixture of an organic solvent and water as a solvent, adding a surfactant to prepare a surfactant solution;

[0067] 3) taking a mixture of an organic solvent and water as a solvent, adding a hydrolysis accelerator to it to prepare a hydrolysis accelerator solution;

[0068] 4) mixing the salt solution and the hydrolysis accelerator solution to obtain a reaction solution;

[0069] 5) adding an oxidizing agent to the reaction solution and mixing to carry out an oxidation reaction until the reaction solution turns yellow;

[0070] 6) Adding the surfactant solution to the discolored reaction solution, mixing and modifying it, and aging ...

Embodiment 1

[0098] A method for preparing an oil-soluble monodisperse nanometer ceria catalyst, comprising the following steps:

[0099] 1) Dissolve 2.50g cerium chloride heptahydrate and 0.03g cobalt nitrate hexahydrate in a mixture of 50ml ethanol and 50ml deionized water to prepare a salt solution;

[0100] 2) Dissolving 0.2 g of sodium dodecylbenzenesulfonate in 20 ml of deionized water to obtain a sodium dodecylbenzenesulfonate solution;

[0101] 3) Dissolve 6ml of ethylenediamine in 50ml of methanol to obtain an ethylenediamine solution;

[0102] 4) Add the salt solution dropwise into the ethylenediamine solution, control the reaction temperature to 40°C, and stir at a rate of 500r / min to obtain a reaction solution;

[0103] 5) Dissolve 1.5ml, 30wt.% hydrogen peroxide aqueous solution in 30ml of deionized water, dropwise add to the reaction solution, control the oxidation reaction temperature to 50°C, stir at 500r / min, the reaction solution turns yellow;

[0104] 6) Pour the sodiu...

Embodiment 2

[0107] A method for preparing an oil-soluble monodisperse nanometer ceria catalyst, comprising the following steps:

[0108] 1) 3.88g cerium sulfate tetrahydrate and 0.016g ferrous chloride tetrahydrate were dissolved in a mixture of 30ml acetic acid and 80ml deionized water to prepare a salt solution;

[0109] 2) 5.40 g of myristic acid was dissolved in 25 ml of ethanol to obtain a myristic acid solution;

[0110] 3) 12.33g of sodium acetate was dissolved in 55ml of deionized water to obtain a sodium acetate solution;

[0111] 4) Pour the ethylenediamine solution into the salt solution, control the reaction temperature to 70°C, and stir at a rate of 1000r / min to obtain a reaction solution;

[0112] 5) Dissolve 1.5ml, 30wt.% hydrogen peroxide aqueous solution in 30ml of deionized water, dropwise add to the reaction solution, control the oxidation reaction temperature to 70°C, stir at 500r / min, the reaction solution turns yellow;

[0113] 6) Pour the myristic acid solution in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com