Double-hydrophilic-group double-ion amide surfactant and preparation method thereof

A technology of surfactant and double ion, which is applied in the field of surfactant preparation, can solve the problems of unable to control the acidity and alkalinity, achieve the effect of improving biodegradability, simple and effective synthesis method, and avoiding by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

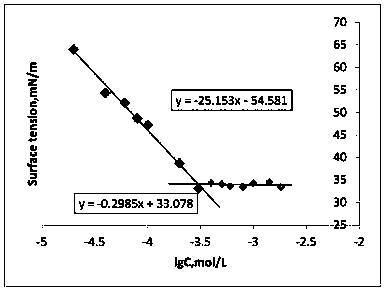

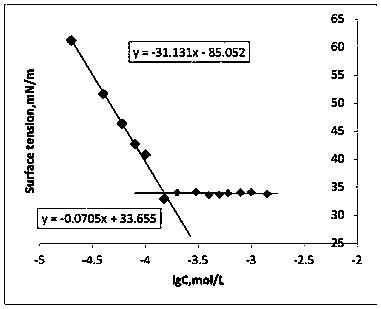

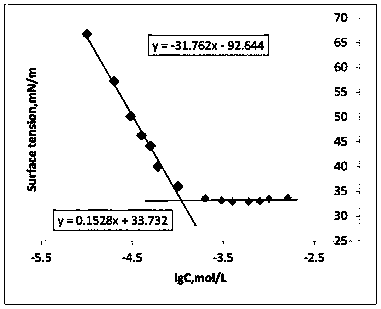

Image

Examples

Embodiment I-1

[0044] Amide surfactant preparation:

[0045] (1) Carboxylic acid amide surfactant I-1 containing carbon chain link

[0046]Preparation method: (1) Weigh 2.32g (20mmol) of 1,6-hexanediamine, add 20mL tetrahydrofuran, stir to dissolve it; weigh 1.09g (4mmol) of di-tert-butyl dicarbonate, and dissolve it with 5mL tetrahydrofuran; keep The system is in an ice-water bath, and the di-tert-butyl dicarbonate solution is slowly added to the 1,6-hexanediamine solution for more than 30 minutes; after the addition is completed, the system is milky white, and the reaction is milky white. Layer chromatography detection (dichloromethane:methanol=5:2, Rf=0.5), after the reaction was completed, THF was removed, 1,6-hexamethylenediamine was washed three times with water, the solvent was spin-dried to obtain a yellow oily liquid, and column chromatography Purification afforded 0.88 g of the product with a yield of 81.4%. (2) Take decylsuccinic anhydride 0.98g (4.1mmol), add 5mL dichloromethan...

Embodiment I-2

[0061] Amide surfactant preparation:

[0062] (1) Containing carboxylic acid amide surfactant I-2 of ether chain link

[0063] (1) Measure 5.84mL (40mmol) of 1,8-diamino-3,6-dioxa-octane in a 250mL round bottom flask, add 45mL tetrahydrofuran, put into a magnet and stir to dissolve it; weigh two Put 2.825g (10mmol) of di-tert-butyl carbonate in a 10mL eggplant-shaped bottle, add 5mL of tetrahydrofuran, and shake it ultrasonically to dissolve it; keep the reaction system in an ice bath, slowly add di-tert-butyl dicarbonate solution dropwise to 1 , 8-diamino-3,6-dioxa-octane solution, the dropping time is more than 30min; the dropping process, the system is milky white, after 24h of reaction, it is detected by thin layer chromatography (triethylamine: 1 drop; two Chloromethane:methanol=5:1, Rf=0.5), reaction is completed, spin-dry tetrahydrofuran, obtains white solid, adds appropriate amount of water, makes the solid dissolution in the system, transfers to separating funnel, ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com