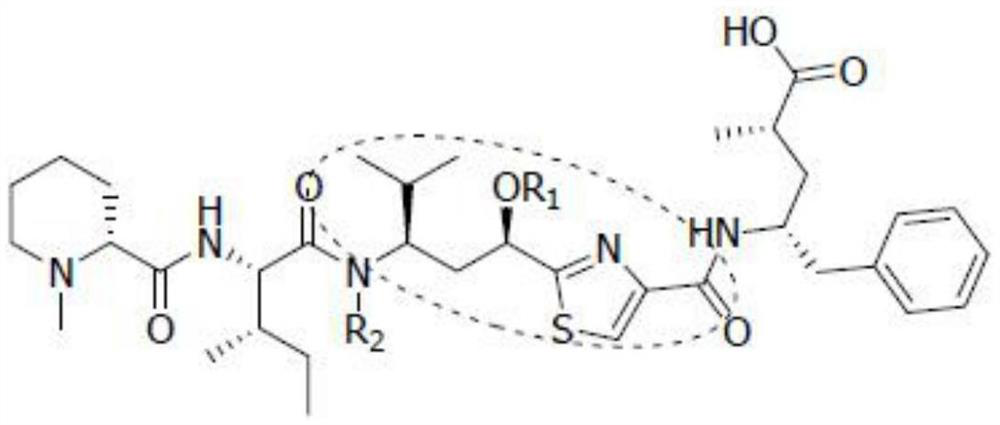

A kind of synthetic method of the key intermediate tuv of natural anticancer drug tubulysins

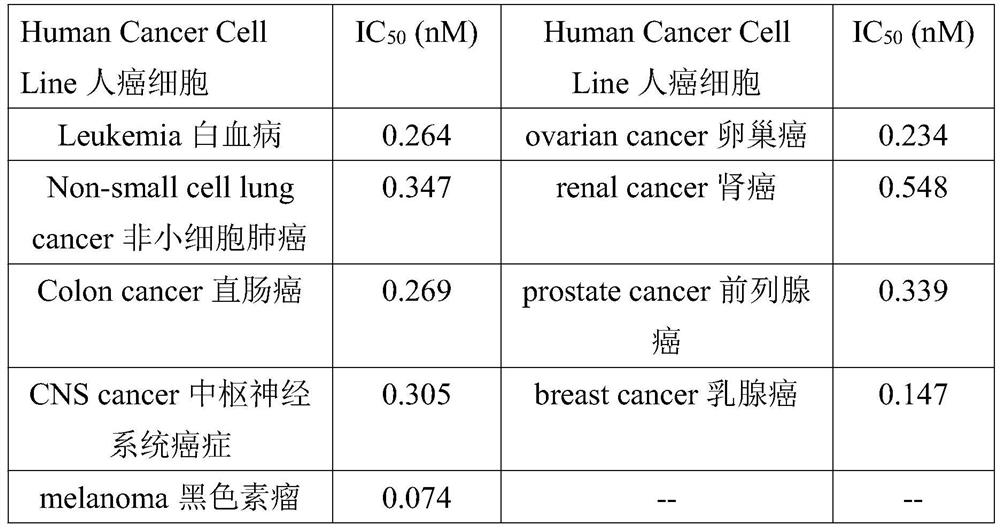

A synthesis method and technology for anticancer drugs, applied in the direction of organic chemistry and the like, can solve the problems of low practicability, difficult amplification and synthesis, complicated operation, etc., and achieve the effects of low cost, simple post-processing process and good stereoselectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

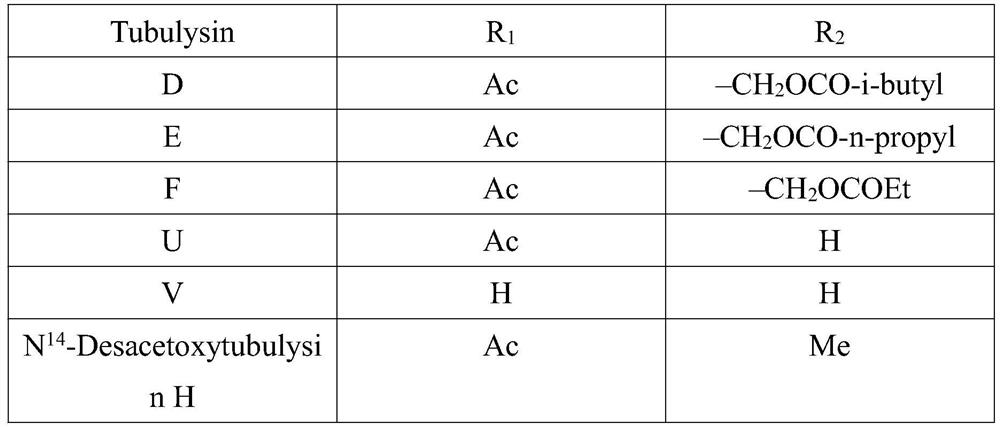

[0063] The present invention provides a kind of synthetic method of the key intermediate Tuv of natural anticancer drug Tubulysins, and the route of described synthetic method is as follows:

[0064]

[0065] Including the following steps:

[0066] Step 1, dissolving the starting material L-valinol 1 in a tetrahydrofuran / water mixed solvent, adding solid sodium bicarbonate and benzyl chloroformate CbzCl, and reacting overnight at room temperature to obtain compound 2;

[0067] Step 2, dissolving the compound 2 obtained in step 1 in acetonitrile, adding 2-iodobenzoic acid, and heating to reflux to obtain the intermediate aldehyde 3;

[0068] Dissolving the intermediate aldehyde 3 in dichloromethane, adding Wittig reagent 4 and tetramethylguanidine, and heating under reflux to obtain compound 5;

[0069] Step 3, dissolving the compound 5 in a tetrahydrofuran / water mixed solvent, adding solid sodium hydroxide, and heating to reflux to obtain the compound 6;

[0070] Using co...

Embodiment approach

[0080] As an embodiment, in the step 3, the molar ratio of compound 5: sodium hydroxide: compound 7: FDPP: triethylamine: triphenylphosphine: DBU: trichlorobromomethane is 1: 10-20: 0.5- 0.55:1-1.2:2-3:5-6:3-4:2-3, preferably 1:15:0.5:1:2:5:3:2.

[0081] As an embodiment, the compound 5 is reacted with sodium hydroxide for 4-6 hours, preferably for 4 hours. After the reaction, it is concentrated under reduced pressure, acidified with dilute hydrochloric acid, extracted three times with ethyl acetate, and the combined organic phases are washed with saturated brine. , liquid separation, the organic phase was dried with anhydrous sodium sulfate, filtered and concentrated to obtain compound 6;

[0082] Then compound 6 was dissolved in dichloromethane, FDPP (pentafluorophenyl diphenyl phosphate) and triethylamine were added, reacted at room temperature for 0.5-1h, preferably 0.5h, and then compound 7 and triphenyl Phosphine, heated to reflux for 7-12 hours, preferably 10 hours, th...

Embodiment 1

[0088] Embodiment 1: the synthesis of compound 2

[0089]

[0090] Dissolve L-valinol 1 (20g, 193.9mmol) in tetrahydrofuran / water (1:1, 800mL) mixed solvent, add sodium bicarbonate (50.4g, 600mmol), stir well and cool to 0 degree with ice-water bath , slowly added benzyl chloroformate CbzCl (27.3mL, 193.9mmol) dropwise, raised to room temperature after 30 minutes and stirred for 12h, concentrated under reduced pressure, diluted with water (200mL), extracted three times with ethyl acetate (300mL), and combined the organic phases , dried over anhydrous sodium sulfate, and concentrated under reduced pressure to obtain compound 2, 43.7 g of white solid, with a yield of 95%. used directly in the next reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com