Core-shell structure composite material and preparation method thereof, and application of core-shell structure composite material in lithium ion battery

A composite material and core-shell structure technology, applied in the field of lithium-ion batteries, can solve the problems of reduced material volume specific capacity, unresolved hard carbon materials, low first-time Coulombic efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

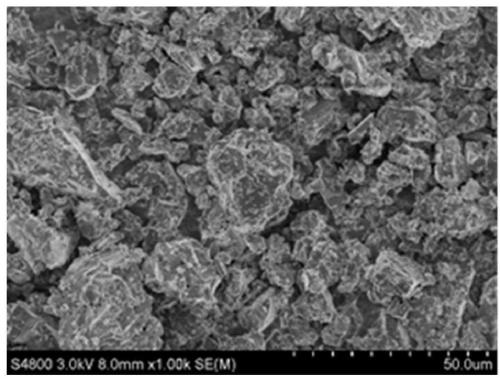

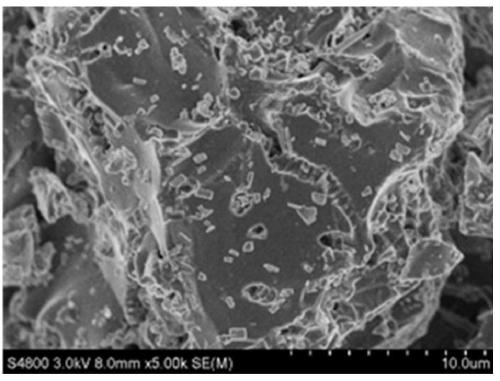

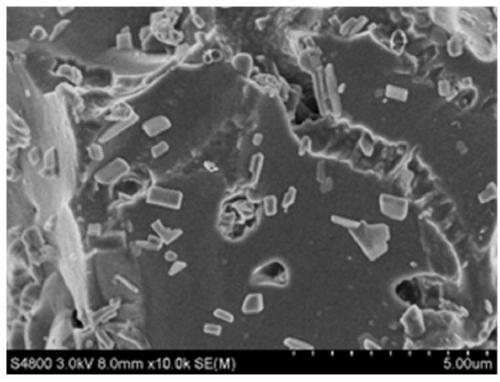

Image

Examples

Embodiment 1

[0083] (1) Using plant-based raw materials as a carbon source to prepare hard carbon materials with a particle size of 5 μm-18 μm, specifically including the steps of crushing, carbonization, and jet milling;

[0084] (2) Disperse the above-mentioned plant-based hard carbon material, lithium titanate nanoparticles with a particle size of 30-250nm, and high-temperature petroleum pitch in propanol at a mass ratio of 80:5:15, and dry by rotary evaporation at 30°C, adjusting the speed Be 30.0r / min, obtain coating material precursor;

[0085] (3) Then put it in a box-type furnace, feed argon gas, raise the temperature to 500°C at a heating rate of 2.0°C / min, keep it warm for 2.0h, and naturally cool to room temperature to obtain the third precursor; the third precursor is pulverized, Sieve and demagnetize to obtain the fourth precursor with a particle size of 5.0-45.0 μm, and finally place it in a box furnace, pass in argon gas, raise the temperature to 1100.0°C at a heating rate o...

Embodiment 2

[0089] (1) Preparing hard carbon materials using plant-based raw materials as a carbon source, specifically including the steps of crushing, carbonization, and jet milling;

[0090] (2) Place the above-mentioned plant-based hard carbon material, lithium titanate nanoparticles with a particle size of 30-250nm, and high-temperature petroleum pitch in a fusion machine at a mass ratio of 80:5:15, and adjust the speed to 2000.0r / min. The gap width is 0.5cm, and the fusion is 0.5h to obtain the coating material precursor;

[0091] (3) Then put it in a box-type furnace, feed argon gas, raise the temperature to 500°C at a heating rate of 2.0°C / min, keep it warm for 2.0h, and naturally cool to room temperature to obtain the third precursor; the third precursor is pulverized, Sieve and demagnetize to obtain the fourth precursor with a particle size of 5.0-45.0 μm, and finally place it in a box furnace, pass in argon gas, raise the temperature to 1100.0°C at a heating rate of 2.0°C / min, ...

Embodiment 3

[0094] (1) prepare hard carbon material, as inner core;

[0095] (2) Disperse lithium titanate nanoparticles with a particle size of 30-250nm and high-temperature coal tar pitch in a mass ratio of 5 parts: 15 parts in propanol, dry by rotary evaporation, adjust the speed to 60.0r / min, and rotate to the slurry Completely disperse evenly to obtain a slurry, then place 80 parts of the hard carbon material inner core in the slurry, and react in a rotary evaporator at 55°C for 4 hours to obtain a coating material precursor;

[0096] (3) Then put it in a box-type furnace, feed nitrogen, raise the temperature to 450.0°C at a heating rate of 3.0°C / min, keep it warm for 6.0h, and naturally cool to room temperature to obtain the third precursor; the third precursor is crushed and sieved Separate and demagnetize to obtain the fourth precursor with a particle size of 5.0-45.0 μm, and finally place it in a box furnace, pass in argon gas, raise the temperature to 900.0°C at a heating rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com