Preparation method and application of a supercapacitor cathode material of graphene/iron oxyhydroxide/polyaniline

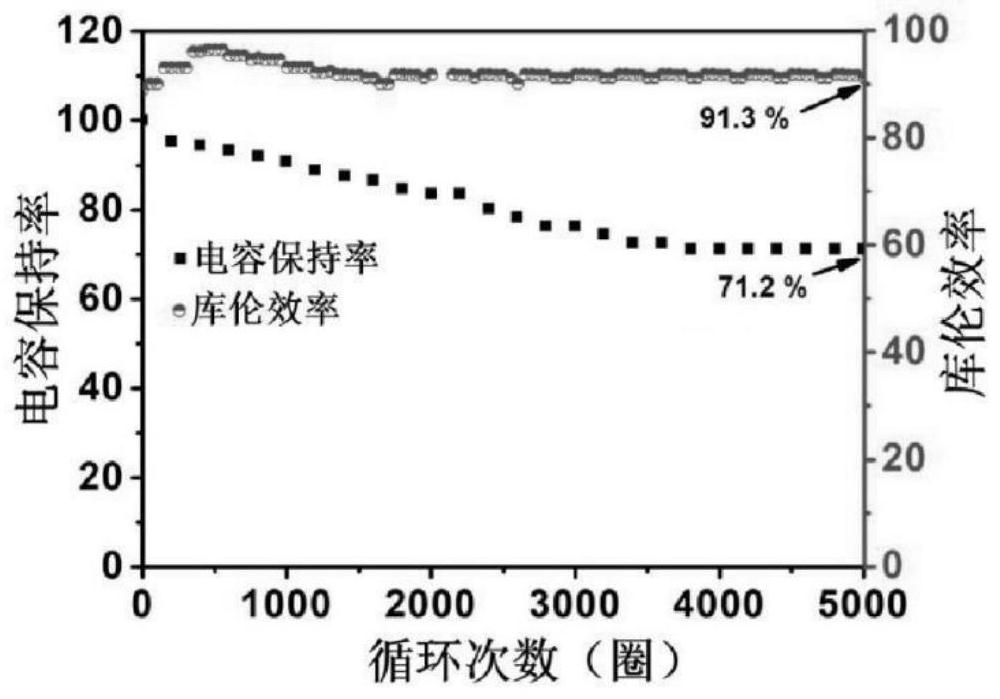

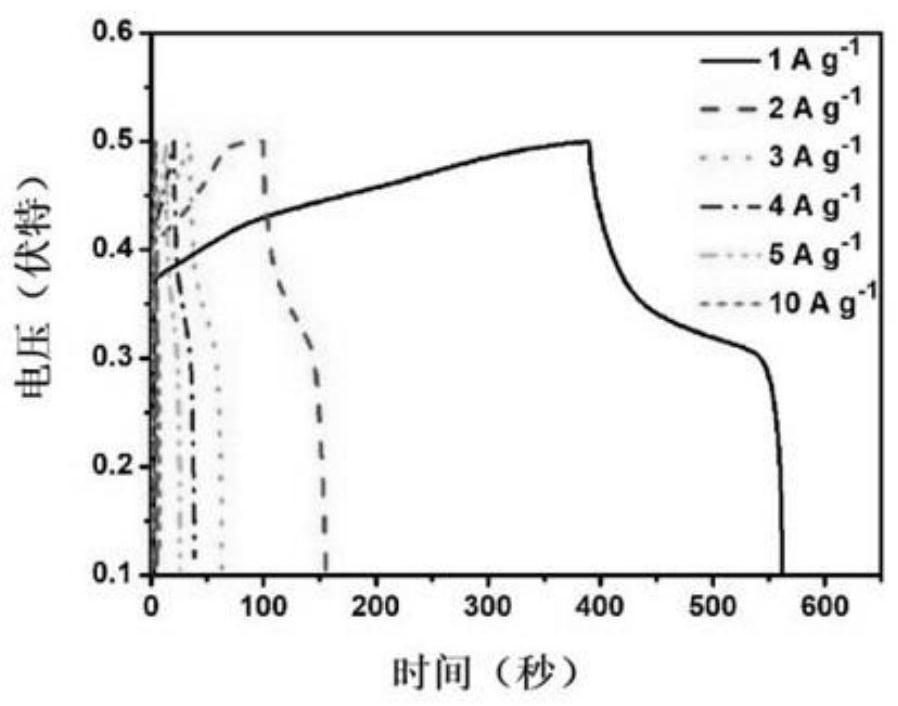

A technology of iron oxyhydroxide and supercapacitor, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of uneven distribution of polyaniline, volume expansion, difficult to control particle size, etc., and achieve enhanced cycle stability , good electrical conductivity, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of supercapacitor cathode material of graphene / iron oxyhydroxide / polyaniline, comprises the following steps:

[0031] 1) Add ammonium persulfate and ferric sulfate to perchloric acid, then add graphene oxide aqueous solution to it and stir at room temperature until a uniform mixture is formed;

[0032] 2) Slowly inject the solution with aniline monomer and sodium citrate as the solute and carbon tetrachloride as the organic solvent into the uniform mixture described in step 1), and finally let it stand at room temperature for several hours, then filter, wash, and vacuum dry.

[0033] The molar ratio of ammonium persulfate, ferric sulfate and graphene oxide in the above step 1) is (0.8-1.5):(0.8-1.5):(2.4-4.5).

[0034] The stirring speed in step 1) above is 300-500 rpm.

[0035] The molar ratio of the aniline monomer and sodium citrate to the ammonium persulfate described in step 1) in the above step 2) is (0.7-1.3): (3.2-3.8): (0.7-2.0).

...

Embodiment 1

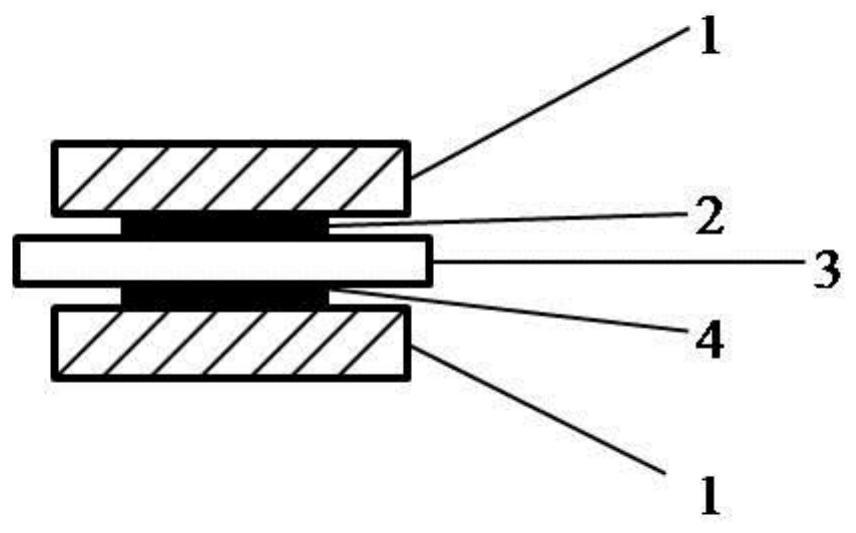

[0044] The preparation method of the asymmetric all-solid-state supercapacitor cathode material of graphene / iron oxyhydroxide / polyaniline comprises the following steps:

[0045] 1) Add 0.02 mol ammonium persulfate and 0.02 mol ferric sulfate to 60 mL perchloric acid, then add 30 mL graphene oxide aqueous solution with a concentration of 2 mol / L and stir at room temperature at a stirring speed of 450 rpm until a homogeneous mixture is formed.

[0046] 2) Dissolve 0.02 mol aniline monomer and 0.07 mol sodium citrate in 30 mL carbon tetrachloride organic solvent to form a solution, slowly inject the solution into the homogeneous mixture obtained in step 1), and finally let it stand at room temperature for 12 hours After filtration, washing, and vacuum drying at 40 ºC for 10 hours, the graphene / iron oxyhydroxide / polyaniline asymmetric all-solid-state supercapacitor cathode material was obtained.

Embodiment 2

[0048] 1) Add 0.01 mol of ammonium persulfate and 0.01 mol of ferric sulfate to 30 mL of perchloric acid, then add 15 mL of graphene oxide aqueous solution with a concentration of 2 mol / L and stir at room temperature at a stirring speed of 450 rpm until A homogeneous mixture is formed.

[0049] 2) Dissolve 0.01 mol aniline monomer and 0.035 mol sodium citrate in 30 mL carbon tetrachloride organic solvent to form a solution, slowly inject the solution into the homogeneous mixture obtained in step 1), and finally let stand at room temperature for 24 hours After filtration, washing, and vacuum drying at 40 ºC for 9 hours, the graphene / iron oxyhydroxide / polyaniline asymmetric all-solid-state supercapacitor cathode material was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com