Synthesis method of boscalid intermediate 2-(4 '-chlorphenyl) aniline

A synthetic method, the technology of boscalid, which is applied in the field of pesticide intermediate synthesis, can solve the problems of unsatisfactory yield, solid waste pollution, and high cost of p-chlorophenylboronic acid raw materials, and achieve low cost, simple operation, and high industrial efficiency. The effect on production value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

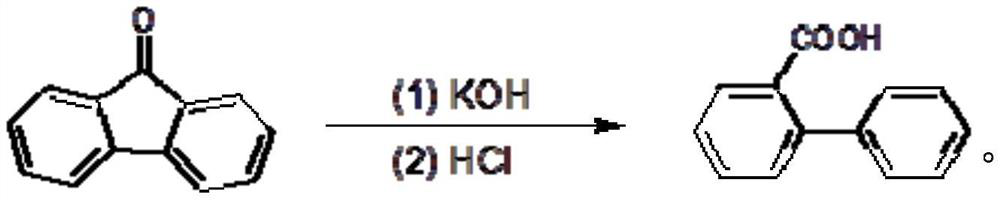

[0048] Embodiment 1: the synthesis of 2-phenylbenzoic acid

[0049] The synthetic route of present embodiment 2-phenylbenzoic acid is as follows:

[0050]

[0051] Specifically: Add 18g (0.1mol) of 9-fluorenone, 42g (0.75mol) of potassium hydroxide and 300mL of toluene into the reaction flask, stir and heat up to 70°C, react for 12 hours, end the reaction, cool down to 25°C, add 500mL water, adjust the pH value to 1-2 with 36-38wt% hydrochloric acid, filter with suction, and dry to obtain the crude product of 2-phenylbenzoic acid with a yield of 96%.

Embodiment 2

[0052] Embodiment 2: the synthesis of 2-phenylbenzoic acid

[0053] The synthetic route of present embodiment 2-phenylbenzoic acid is the same as embodiment 1.

[0054] Specifically: add 33.6g (0.3mol) potassium tert-butoxide and 400mL tetrahydrofuran into the reaction flask, then add 18g (0.1mol) 9-fluorenone in batches, after the addition is complete, stir the reaction at 25°C for 1 hour, and monitor the completion of the reaction by HPLC Afterwards, concentrate to remove the organic solvent, add 500mL of water, adjust the pH value to 1-2 with 36-38wt% hydrochloric acid, filter with suction, and dry to obtain crude 2-phenylbenzoic acid with a yield of 99%.

Embodiment 3

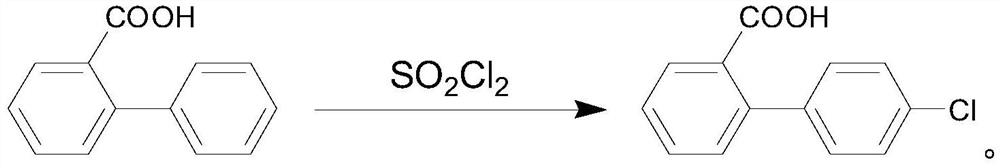

[0055] Embodiment 3: the synthesis of 2-(4'-chlorophenyl) benzoic acid

[0056] The synthetic route of present embodiment 2-(4'-chlorophenyl) benzoic acid is as follows:

[0057]

[0058] Specifically: 10g (0.05mol) of 2-phenylbenzoic acid and 50mL of dichloroethane prepared in Example 1 or 2 were added to the reaction flask, the temperature was raised to 70°C, and 10.22g (0.75mol) was added dropwise within 2 hours. After the addition of sulfuryl chloride was completed, the reaction was carried out for 4 hours, and the solvent was recovered by distillation under reduced pressure to obtain the crude product of 2-(4'-chlorophenyl)benzoic acid with a yield of 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com