Preparation method of a wound repair material with cell growth regulation function

A wound repair and cell growth technology, applied in filament/thread forming, bandages, fiber treatment, etc., can solve the problems of inability to achieve precise regulation of cell growth genes, difficult to meet the needs of wound repair material design, etc., to isolate bacterial invasion As well as infection, reducing secondary damage, and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

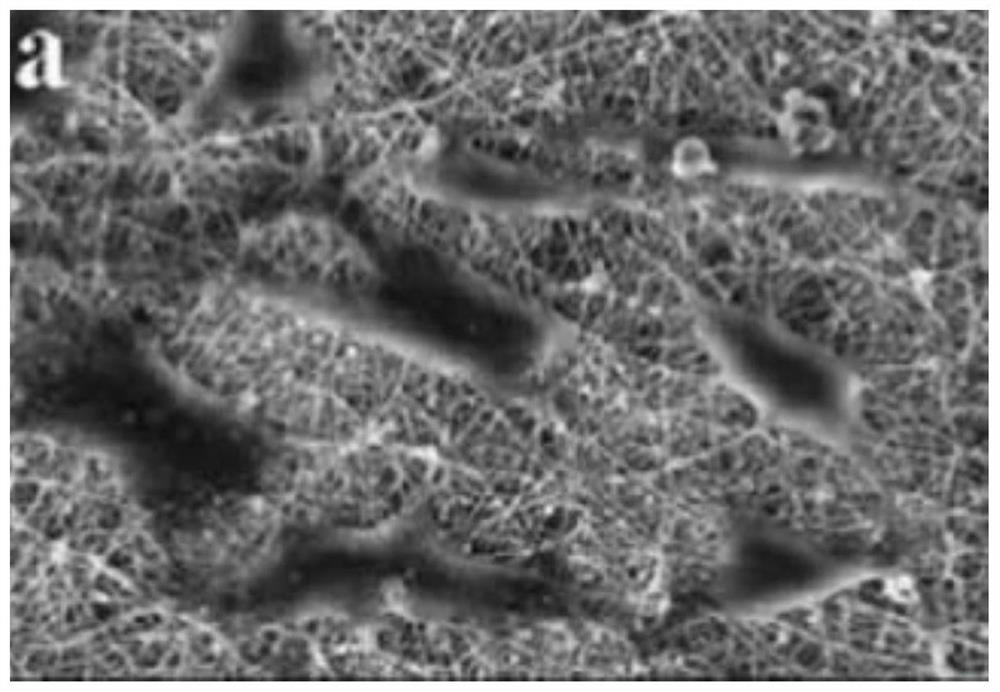

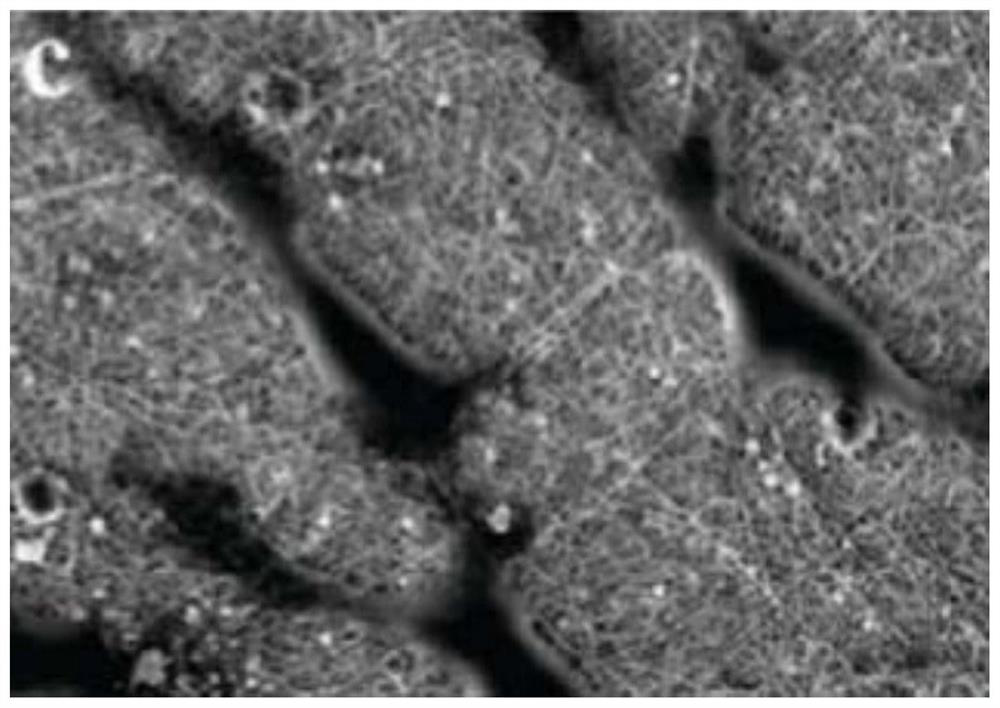

Image

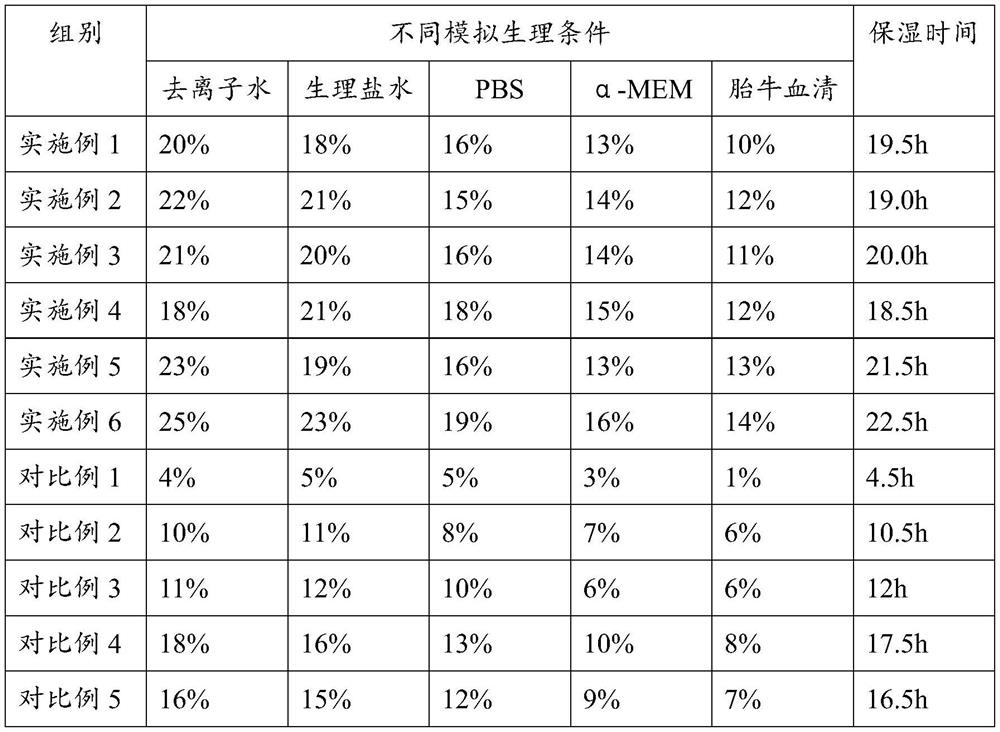

Examples

Embodiment 1

[0035] A preparation method of a wound repair material with cell growth regulation function, comprising the following steps:

[0036] S1. In the glass container, add 0.4g polycaprolactone (the number average molecular weight is 50000) and 0.2g nanometer bioactive glass powder (CaO-P 2 o 5 -SiO 2 system, SiO 2 59wt%, P 2 o 5 5wt%, CaO 36wt%) in 5ml hexafluoroisopropanol, to obtain a solution with a mass volume ratio concentration of 0.12g / ml, the solution was magnetically stirred at room temperature for 12h to dissolve completely, and was prepared as an electrospinning precursor solution;

[0037] S2. Inhale the electrospinning precursor solution configured in step S1 into the syringe fixed on the propulsion pump to carry out the electrospinning process. The propulsion rate of the propulsion pump is 1.4 ml / hour and the flow rate of the spinning solution is kept stable. The spinning nozzle is a diameter of It is a flat needle of 0.4 mm, connected to the positive electrode...

Embodiment 2

[0044] A preparation method of a wound repair material with cell growth regulation function, comprising the following steps:

[0045] S1. In the glass container, add 0.6g polyvinyl alcohol and 0.3g nano bioactive glass powder (CaO-P 2 o 5 -SiO 2 system, SiO 2 50wt%, P 2 o 5 20wt%, CaO 30wt%) into 6ml of acetone, to obtain a solution with a mass volume ratio concentration of 0.16g / ml, the solution was magnetically stirred at room temperature for 12h to dissolve completely, and was prepared as an electrospinning precursor solution;

[0046] S2. Inhale the electrospinning precursor solution configured in step S1 into the syringe fixed on the propulsion pump to carry out the electrospinning process. The propulsion rate of the propulsion pump is 1.5 ml / hour and the flow rate of the spinning solution is kept stable. The spinning nozzle is a diameter of It is a flat needle of 0.4 mm, connected to the positive pole of 20 kV high-voltage DC power supply, the distance between the s...

Embodiment 3

[0053] A preparation method of a wound repair material with cell growth regulation function, comprising the following steps:

[0054] S1. In the glass container, add 1.0g polylactic acid-glycolic acid copolymer (the number average molecular weight is 50000) and 0.5g nanometer bioactive glass powder (CaO-P 2 o 5 -SiO 2 system, SiO 2 60wt%, P 2 o 5 14wt%, CaO 26wt%) into 10ml tetrahydrofuran, to obtain a solution with a mass volume ratio concentration of 0.20g / ml, the solution was magnetically stirred at room temperature for 12h to dissolve completely, and was prepared as an electrospinning precursor solution;

[0055] S2. Inhale the electrospinning precursor solution configured in step S1 into the syringe fixed on the propulsion pump to carry out the electrospinning process. The propulsion rate of the propulsion pump is 1.5 ml / hour and the flow rate of the spinning solution is kept stable. The spinning nozzle is a diameter of It is a flat needle of 0.4 mm, connected to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com