A modified conductive polymer-coated silicon-based negative electrode material and its preparation method and application

A technology of conductive polymers and negative electrode materials, applied in the direction of active material electrodes, negative electrodes, battery electrodes, etc., can solve the problems of low compaction density and easy crushing, and achieve the goal of inhibiting agglomeration, inhibiting volume expansion, and improving cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

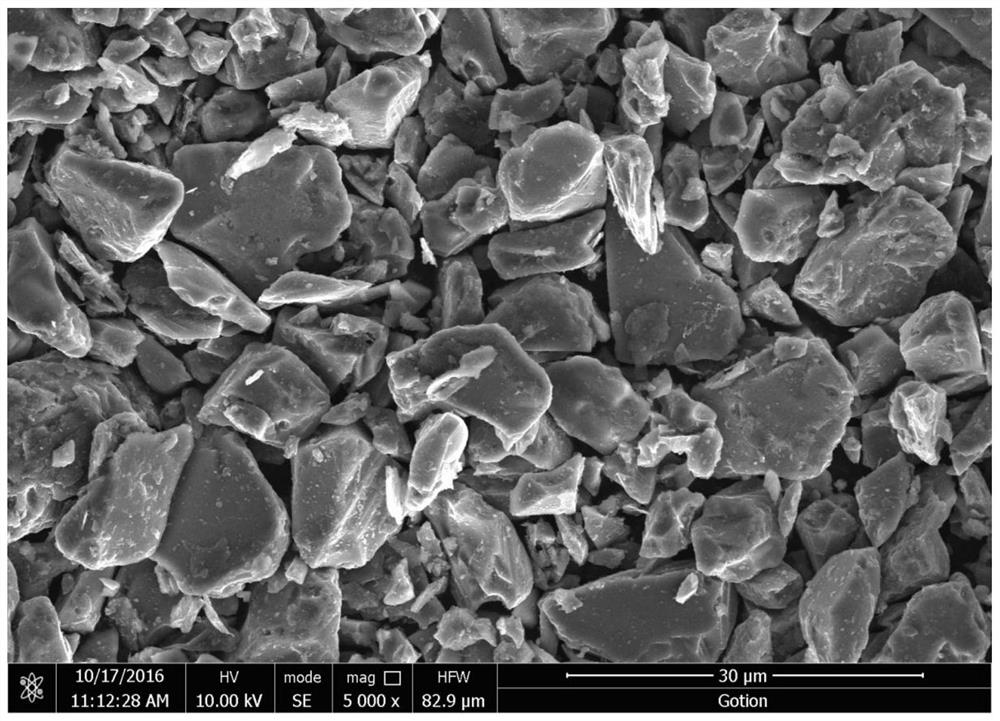

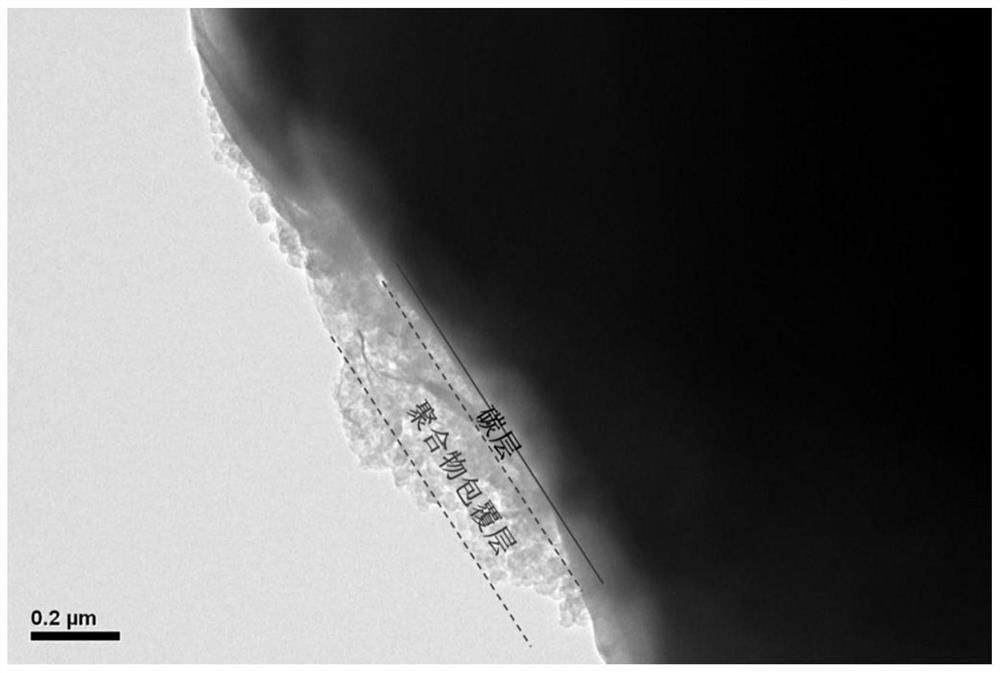

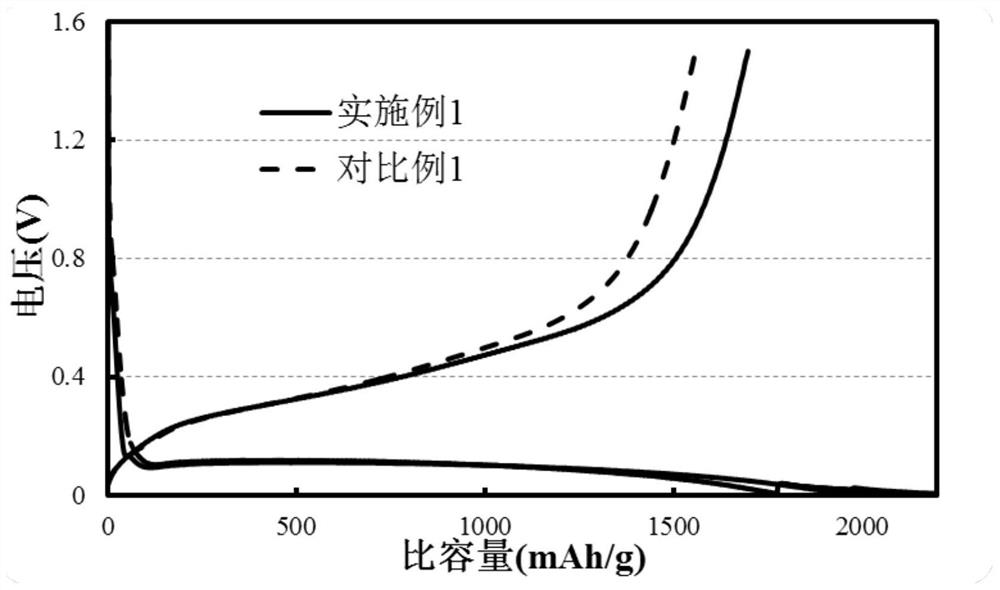

[0032]Put silicon oxide (SiO) in a rotary kiln protected by nitrogen gas, and after raising the temperature to 1100°C at a rate of 5°C / min, feed a mixture of nitrogen and acetylene with a volume ratio of 1:1 and keep it warm for 0.5h. During the whole sintering process, the rotation speed of the rotary kiln was kept at 2r / min, and the material was discharged at room temperature to obtain a CVD-coated SiO / C material, which was designated as product A. Add 6g of dodecylbenzenesulfonic acid into a beaker and place it in an ice bath, then add 14mL of deionized water to the beaker for emulsification, stir and mix evenly, then take 30g of product A and add it to the above emulsion, mix evenly to obtain an emulsion b. Add 3g of epoxy acrylic resin to 12g of tetrahydrofuran, stir well to obtain solution C, then add solution C to emulsion B, mix well to obtain mixed solution D, then add 9g of aniline dropwise to mixed solution D, mix well Then add 9g of hydrogen peroxide and 10mL of d...

Embodiment 2

[0036] Put silicon oxide (SiO) in a rotary kiln protected by helium gas, raise the temperature to 800°C at a rate of 5°C / min, and then feed a mixed gas of helium and methane with a volume ratio of 5:1 and keep it warm for 6 hours During the whole sintering process, the rotating speed of the rotary kiln was kept at 0.1r / min, and the material was discharged at room temperature to obtain a CVD-coated SiO / C material, which was designated as product A. Add 6g of dodecylbenzenesulfonic acid into a beaker and put it in an ice bath, then add 54mL of deionized water to the beaker for emulsification, stir and mix evenly, then take 60g of product A and add it to the above emulsion, mix evenly to obtain an emulsion b. Add 3g of epoxy acrylic resin to 4.5g of tetrahydrofuran, stir well to obtain solution C, then add solution C to emulsion B, mix well to obtain mixed solution D, then add 3g of aniline dropwise to solution D, mix well Then add 9g of hydrogen peroxide and 10mL of deionized w...

Embodiment 3

[0038] Put silicon oxide (SiO) in a rotary kiln protected by argon gas, raise the temperature to 900°C at a rate of 5°C / min, and then feed a mixed gas of argon and ethylene with a volume ratio of 2:1 and keep it warm for 4 hours During the whole sintering process, the rotating speed of the rotary kiln was kept at 0.5r / min, and the material was discharged at room temperature to obtain a CVD-coated SiO / C material, which was designated as product A. Add 6g of dodecylbenzenesulfonic acid into a beaker and put it in an ice bath, then add 34mL of deionized water to the beaker for emulsification, stir and mix evenly, then take 40g of product A and add it to the above emulsion, mix evenly to obtain an emulsion b. Add 3g of epoxy acrylic resin to 7g of tetrahydrofuran, stir well to obtain solution C, then add solution C to emulsion B, mix well to obtain mixed solution D, then add 6g of thiophene dropwise to solution D, mix well Add 12g of hydrogen peroxide and 10mL of deionized water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com