Chitosan/polycaprolactone composite nanofiber membrane material and application thereof

A composite nanofiber and polycaprolactone technology, applied in fiber processing, fiber chemical characteristics, single-component polyester rayon, etc., can solve the problem of unpredictable, composite wound dressings that cannot meet skin wound dressings, limitations Wound dressing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

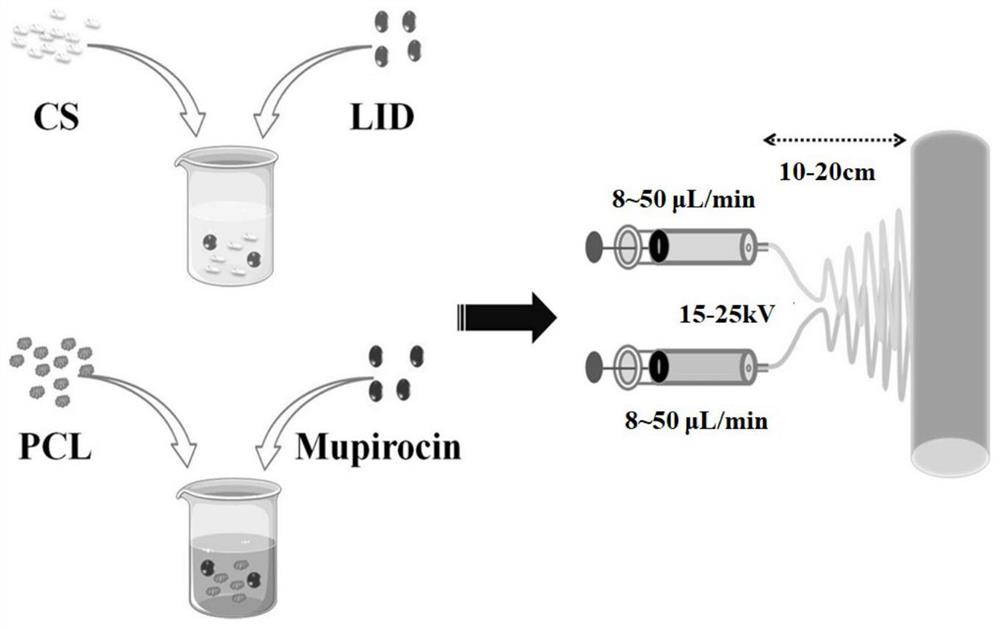

[0038] Example 1 Preparation of CSLD-PCLM nanofiber membrane

[0039] A preparation process of CSLD-PCLM nanofiber membrane, comprising the following steps:

[0040] 1. Preparation of PCL polymer solution: add an appropriate amount of HFIP / DCM organic solvent at a volume ratio of 1:3 to prepare a 10wt% (ie, 100ml solution includes 10g PCL polymer) PCL solution, and magnetically stir overnight at room temperature to obtain a homogeneous solution. Subsequently, 2wt% mupirocin was added to the PCL solution and stirred for 24 hours.

[0041] 2. Preparation of CS polymer solution: 8 wt% CS was dissolved in 30% DCM and 70% TFA for 48 hours, then 1 wt% LID was dissolved in CS solution and stirred for 12 hours.

[0042] 3. Preparation of CSLD-PCLM nanofiber membrane: using double-spinneret electrospinning technology, specifically, the two polymer solutions prepared above were loaded into two syringe pumps (Longer Precision Pump, Baoding, China) respectively. ), the syringe pump con...

Embodiment 2

[0047] The variables of electrospinning are set to prepare CSLD-PCLM nanofiber membranes under different variables, and the specific preparation method is the same as that of Example 1. Table 1 shows the prepared CSLD-PCLM composite nanofibers under different electrospinning variables.

[0048]

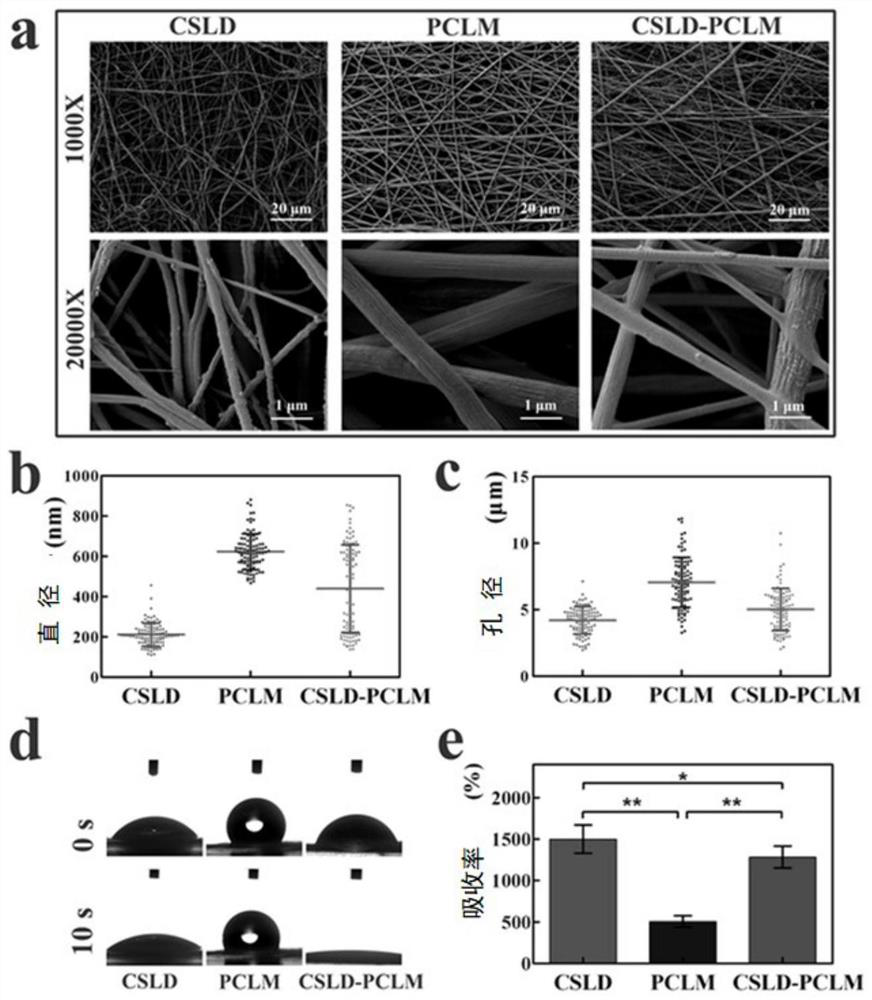

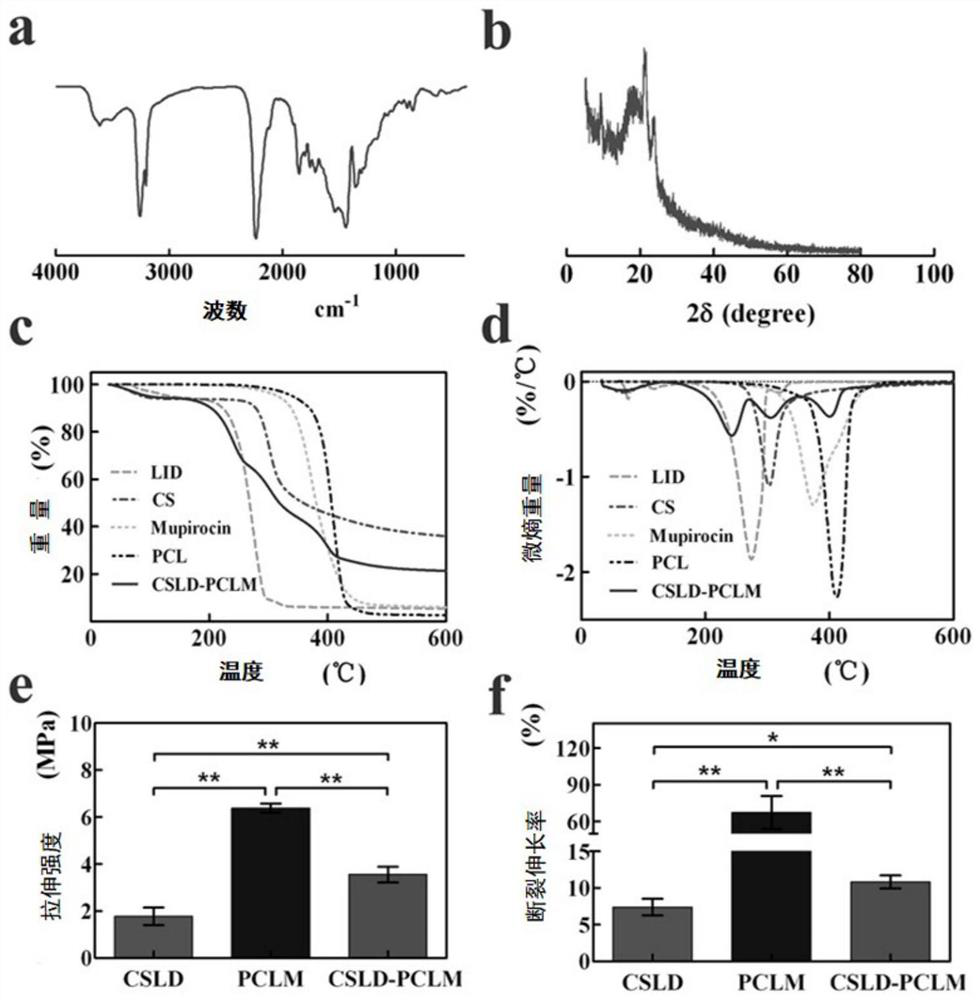

[0049] Using SEM to observe the surface morphology of the composite nanofiber material prepared in embodiment 1 and embodiment 2a-2f, it is concluded that the PCL-M fiber and CS-LID fiber form are the best in the composite nanofiber prepared in embodiment 1, followed by the implementation Composite nanofibers of Examples 2a and 2b and Example 2d. When the present invention adjusts the above-mentioned electrospinning variables beyond the range of variables explored by the present invention, the composite nanofibers fail to form filaments, the filament formation rate is low, or the fiber morphology is different after filament formation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com