Monodisperse nano copper particles used for conductive printing ink and preparation method and purposes thereof

A nano-copper and particle technology, which is applied in the fields of nanotechnology, ink, and nanotechnology for materials and surface science, can solve problems such as being unsuitable for large-scale production, small product particles, and cumbersome post-processing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add 2.0g of PVP-k30 into 200ml of ethanol, stir mechanically, then add 6.0g of L-ascorbic acid, stir evenly, add copper hydroxide aqueous solution, which contains 0.98g of copper hydroxide, heat to 80°C, and wait until the color of the solution starts to change Reheat for 1 hour, cool to room temperature after the reaction is completed, centrifuge and wash 4 times with 8000r / min absolute ethanol, take the precipitate and dry it at room temperature for 10 hours under the condition that the vacuum degree is less than 0.01MPa, and obtain conductive ink nano-copper;

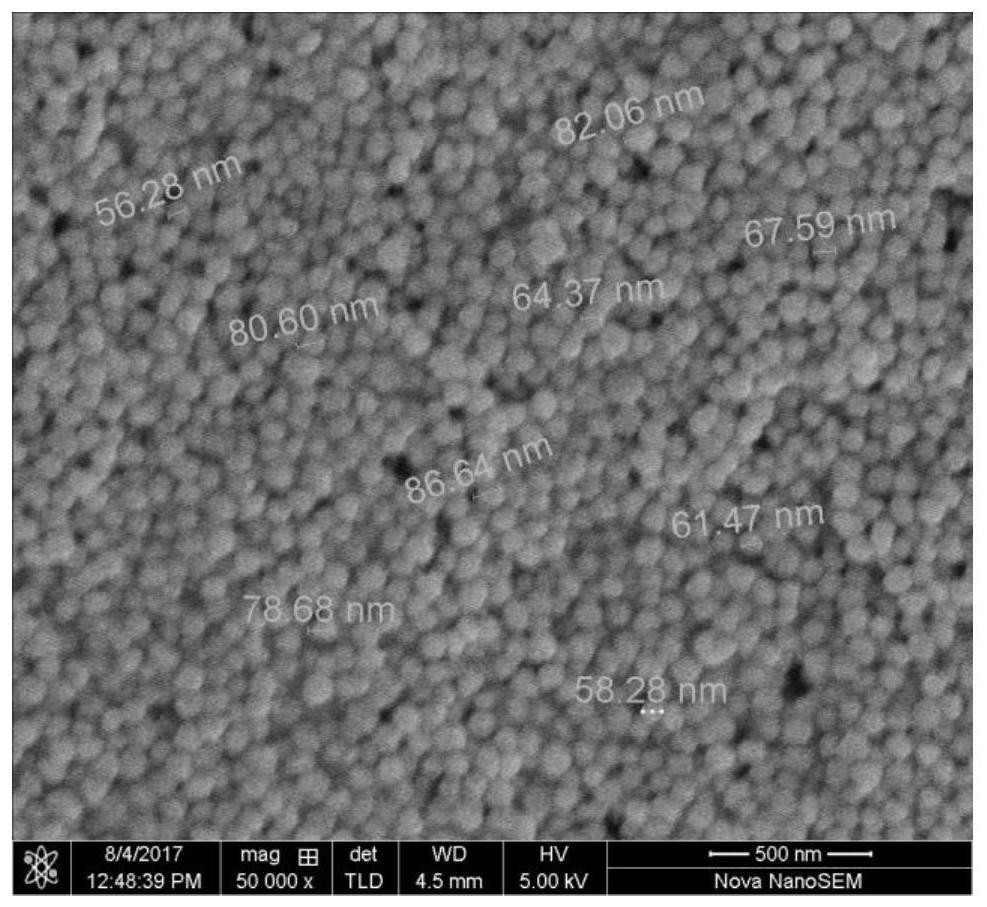

[0038] Get the above-mentioned obtained nano-copper, and use a field-scanning electron microscope (SEM) to observe the morphology of the particles, the results are as follows figure 1 As shown, the particle size of the nano-copper is 50-80nm, the particle dispersion is good, and there is no obvious agglomeration phenomenon.

Embodiment 2

[0040] Add 1.0g PVP-k30 into 200ml ethanol, stir mechanically, then add 6.0g L-ascorbic acid, stir well, add copper hydroxide aqueous solution, which contains 0.98g copper hydroxide, heat to 80°C, wait until the color of the solution starts to change Reheat for 1 hour, cool to room temperature after the reaction is completed, centrifuge and wash 4 times with 8000r / min absolute ethanol, take the precipitate and dry it at room temperature for 10 hours under the condition that the vacuum degree is less than 0.01MPa, and obtain conductive ink nano-copper;

[0041] Take the nano-copper obtained above, and use a field scanning electron microscope (SEM) to observe the morphology of the particles. The particle size of the nano-copper is 60-70nm.

Embodiment 3

[0043]Add 0.5g of PVP-k30 to 200ml of ethanol, stir mechanically, then add 6.0g of L-ascorbic acid, stir evenly, add copper hydroxide aqueous solution, which contains 0.98g of copper hydroxide, heat to 80°C, and wait for the color of the solution to change Reheat for 1 hour, cool to room temperature after the reaction is completed, centrifuge and wash 4 times with 8000r / min absolute ethanol, take the precipitate and dry it at room temperature for 10 hours under the condition that the vacuum degree is less than 0.01MPa, and obtain conductive ink nano-copper;

[0044] Take the nano-copper obtained above, and use a field emission scanning electron microscope (SEM) to observe the morphology of the particles. The particle size of the nano-copper is 80-100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com