Indium sulfide film and preparation method thereof, and inorganic perovskite solar cell based on indium sulfide film and preparation method thereof

A technology of solar cells and indium sulfide, applied in the field of solar cells, can solve the problems of incomplete coverage of conductive glass substrates, decreased battery output performance, and poor device performance, and achieves low preparation costs, less raw materials, and enhanced separation with the effect of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

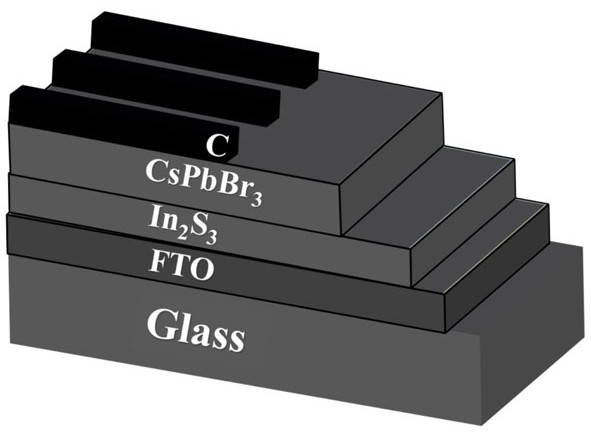

[0045] The invention provides a kind of preparation method of indium sulfide thin film, comprises the following steps:

[0046] Mix thioglycolic acid, ethylene glycol methyl ether and a soluble salt of indium, and perform magnetic stirring at room temperature to obtain In 2 S 3 Precursor solution; the In 2 S 3 The temperature of the precursor solution was raised to 80-120°C, and condensed and refluxed to obtain In 2 S 3 sol, then In 2 S 3 The sol is coated on the conductive glass to obtain In 2 S 3 film.

[0047] Preferably, it also includes the use of organic filter membranes to obtain In 2 S 3 The sol is purified by filtration; preferably, the pore size of the organic filter membrane is 0.45 μm.

[0048] Preferably, the time for magnetic stirring is 10-30 min.

[0049] Preferably, during the heating process, the heating rate is 5-15° C. / min; the condensed reflux time is 1.5-2.5 hours.

[0050] Preferably, the soluble salt of indium is indium trichloride; more pr...

Embodiment 1

[0070] A kind of preparation method of indium sulfide film of the present invention, comprises the steps:

[0071] Take 2 mL of thioglycolic acid, 38 mL of ethylene glycol methyl ether and 4 mmol of indium trichloride tetrahydrate (InCl 3 4H 2 O) In a round bottom flask, magnetically stir at room temperature for 10 min to form In 2 S 3 Precursor solution, the In 2 S 3 The temperature of the precursor solution was raised to 100°C, the heating rate was 5°C / min, and kept in the state of condensing and reflux for 2h to obtain In 2 S 3 Sol, filter In with a 0.45 μm organic nylon filter 2 S 3 sol, to obtain purified In 2 S 3 Sol. Take 90 μL of purified In 2 S 3 The sol was drop-coated on the FTO conductive glass, coated at 3000rpm for 30s, and annealed at 300°C for 1h under Ar to obtain an indium sulfide film.

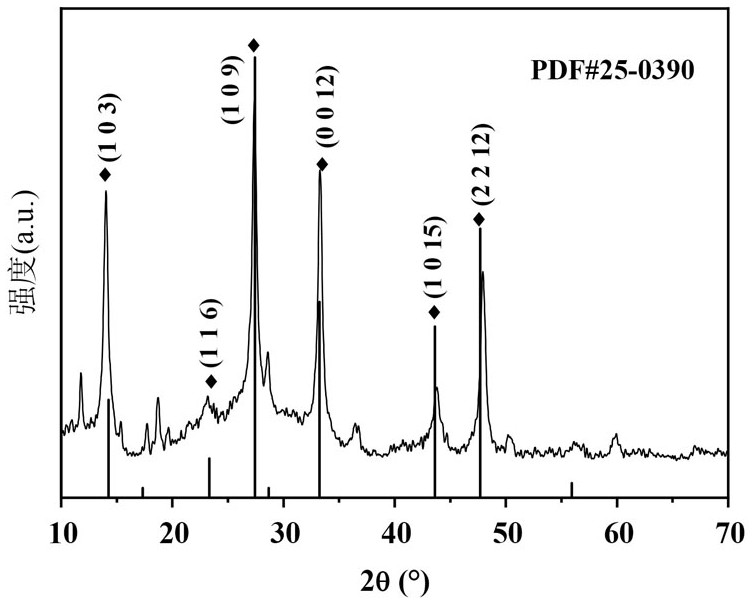

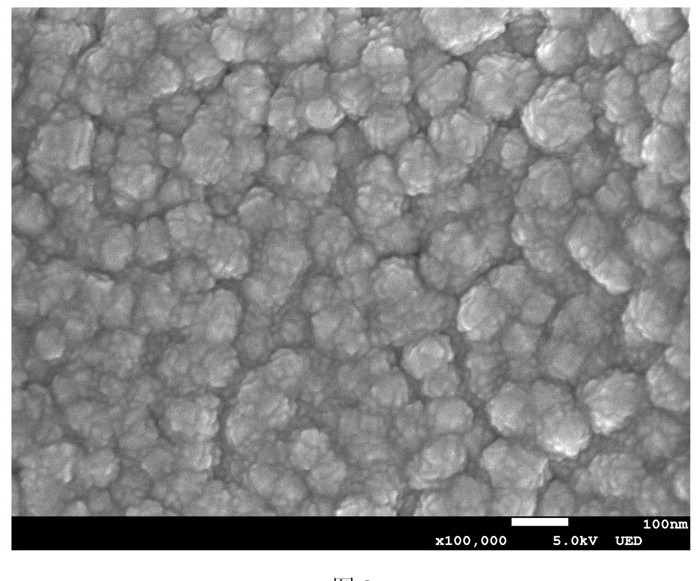

[0072] For income In 2 S 3 The thin film is subjected to XRD test, and the results are as follows: figure 1 shown. Depend on figure 1 It can be seen that t...

Embodiment 2

[0100] The only difference between this embodiment and embodiment 1 is that the preparation of In by spin coating 2 S 3 The spin-coating rotation speed of the thin film was 2000 rpm. By controlling the coating speed to control In 2 S 3 The thickness of the film, the lower the spin coating speed, the thicker the film.

[0101] For the resulting FTO / In 2 S 3 / CsPbBr 3 The cross-section was tested by SEM, the results are as follows Figure 11 shown. Depend on Figure 11 It can be seen that In 2 S 3 Thin film thickness is 240nm, based on In 2 S 3 CsPbBr 3 The performance of perovskite solar cells is tested by J-V, and the test results are as follows: Figure 12 shown. The result is a short circuit current density of 5.86mA / cm 2 , the open circuit voltage is 1.34V, the fill factor is 60%, and the photoelectric conversion efficiency is 4.74%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com