Titanium-containing taphole repairing stemming and preparation method thereof

A taphole and taphole clay technology is applied in the field of repairing taphole clay containing titanium and its preparation. Erosion and scour capability, improved plasticity, low benzopyrene content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

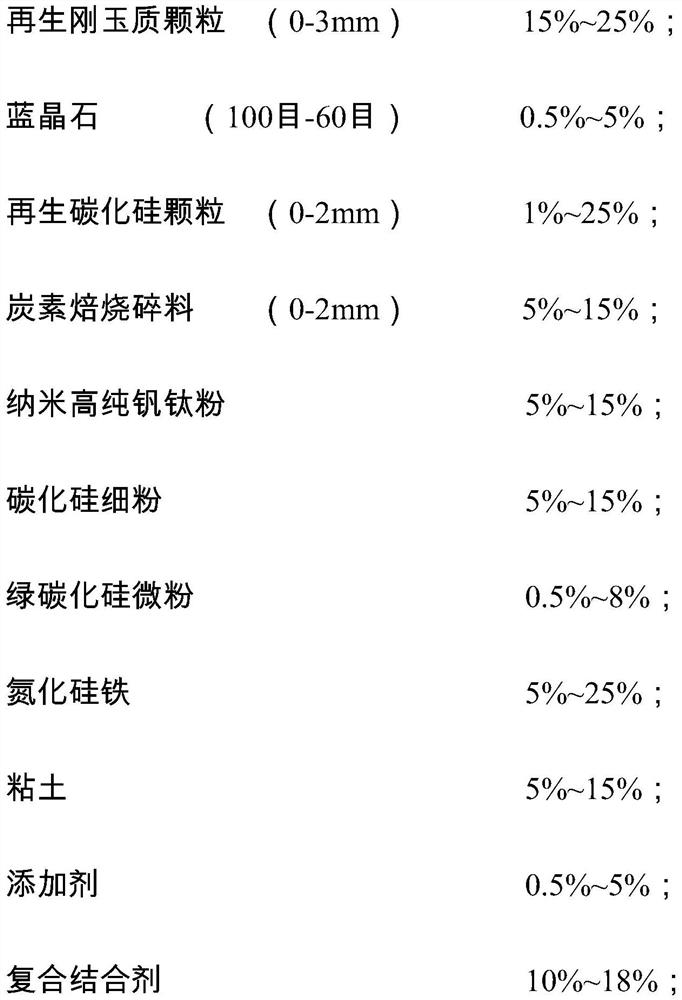

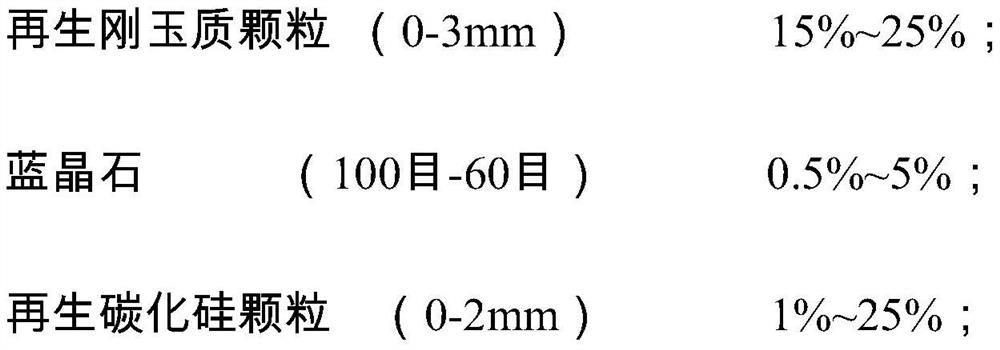

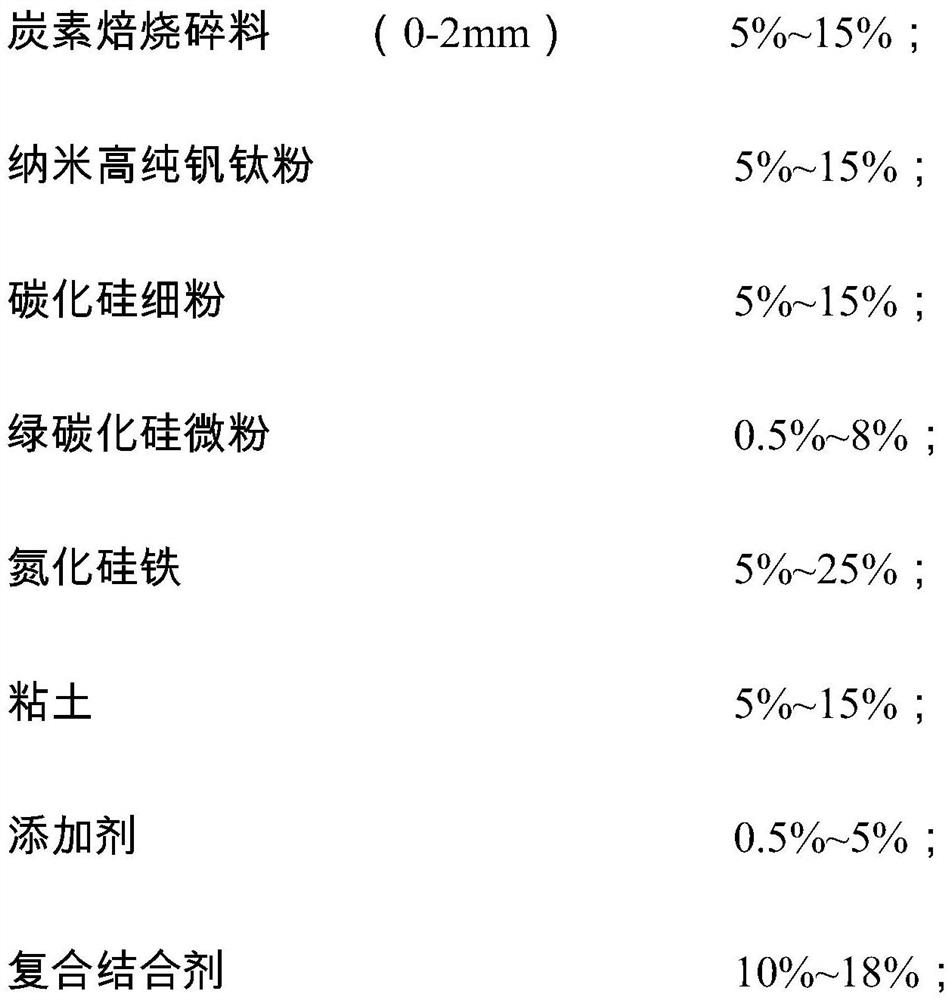

[0034] A titanium-containing taphole repair clay is prepared from raw materials including the following mass percentages:

[0035]

[0036]

[0037] Wherein, the mass ratio of environment-friendly coal tar, environment-friendly high-temperature asphalt and wetting agent in the composite binder is 91%:7%:2%.

[0038] A method for preparing titanium-containing taphole repair clay, comprising the following steps:

[0039] (1) Weigh each raw material according to the formula, and mix the environment-friendly coal tar, environment-friendly high-temperature asphalt and wetting agent evenly to obtain a composite binder;

[0040] (2) Add the remaining raw materials into the mixer and dry mix for 5 minutes, then add a composite binder with a temperature of 60±5°C and stir and mix for 35 to 40 minutes to prepare a mixed mud. When the temperature of the mixed mud reaches 65±5 ℃, sampling to detect the Marshall value;

[0041] (3) After the Masha value measurement is qualified, th...

Embodiment 2

[0045] This example is basically the same as Example 1, except that a titanium-containing taphole repair clay is prepared from raw materials including the following mass percentages:

[0046]

[0047]

[0048] Wherein, the mass ratio of environment-friendly coal tar, environment-friendly high-temperature asphalt and wetting agent in the composite binder is 90.5%:8%:1.5%.

[0049] The repair gun mud product that present embodiment 2 makes is 1080m in volume 3 After 24 hours of use, the surface temperature of the hearth above the iron mouth area dropped from 284°C to 266°C, and after one week of use, the temperature dropped to 242°C, and after one month of use, the temperature dropped to about 198°C and remained stable. The mouth depth is stable at about 2.6 meters, and the average tapping time is about 87 minutes, which not only greatly reduces the labor intensity in front of the furnace, but also improves the working environment in front of the furnace.

Embodiment 3

[0051] This example is basically the same as Example 1, except that a titanium-containing taphole repair clay is prepared from raw materials including the following mass percentages:

[0052]

[0053] Wherein, the mass ratio of environment-friendly coal tar, environment-friendly high-temperature asphalt and wetting agent in the composite binder is 90.2%:8%:1.8%.

[0054] The repair gun mud product that present embodiment 3 makes is 1120m in volume 3 For use on blast furnaces, the splashing time on the first day of use is reduced from the full spraying time to within 30 minutes, and after 3 days, the spraying time is reduced to within 10 minutes, and after one week, the spraying time does not exceed 5 minutes. After 15 days, the iron gate can be opened Flow within 3 minutes, which greatly reduces the slag cleaning work in front of the furnace and reduces the use of consumables in front of the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com