Double-injection multiplication type organic photoelectric detector and preparation method thereof

A photodetector and double-injection technology, which is applied in photovoltaic power generation, electric solid-state devices, semiconductor/solid-state device manufacturing, etc., can solve the problem of low dark current, achieve the effects of reducing photocurrent, improving external quantum efficiency, and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

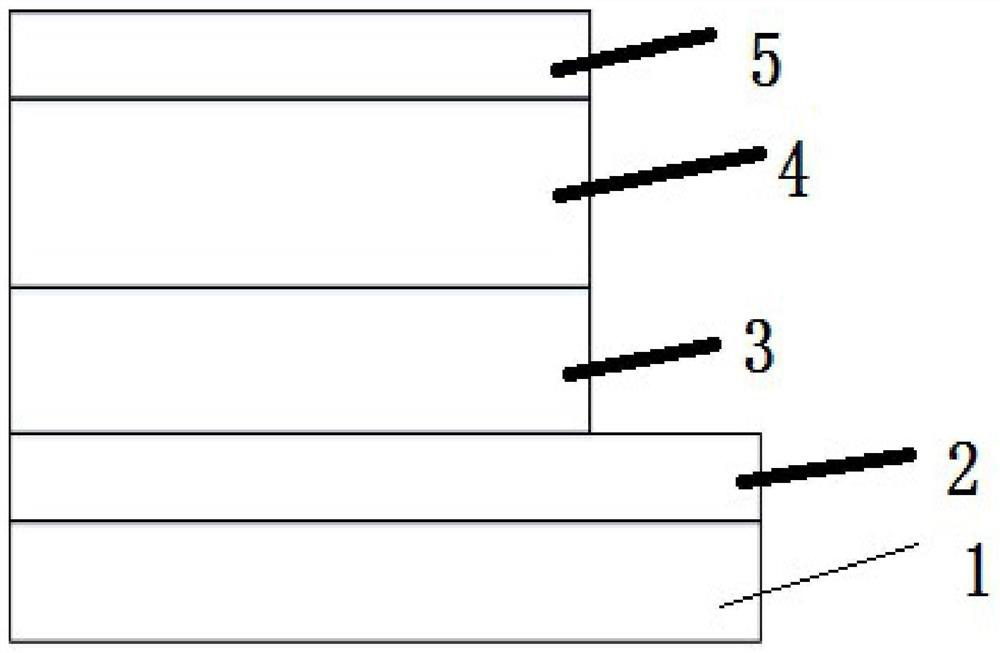

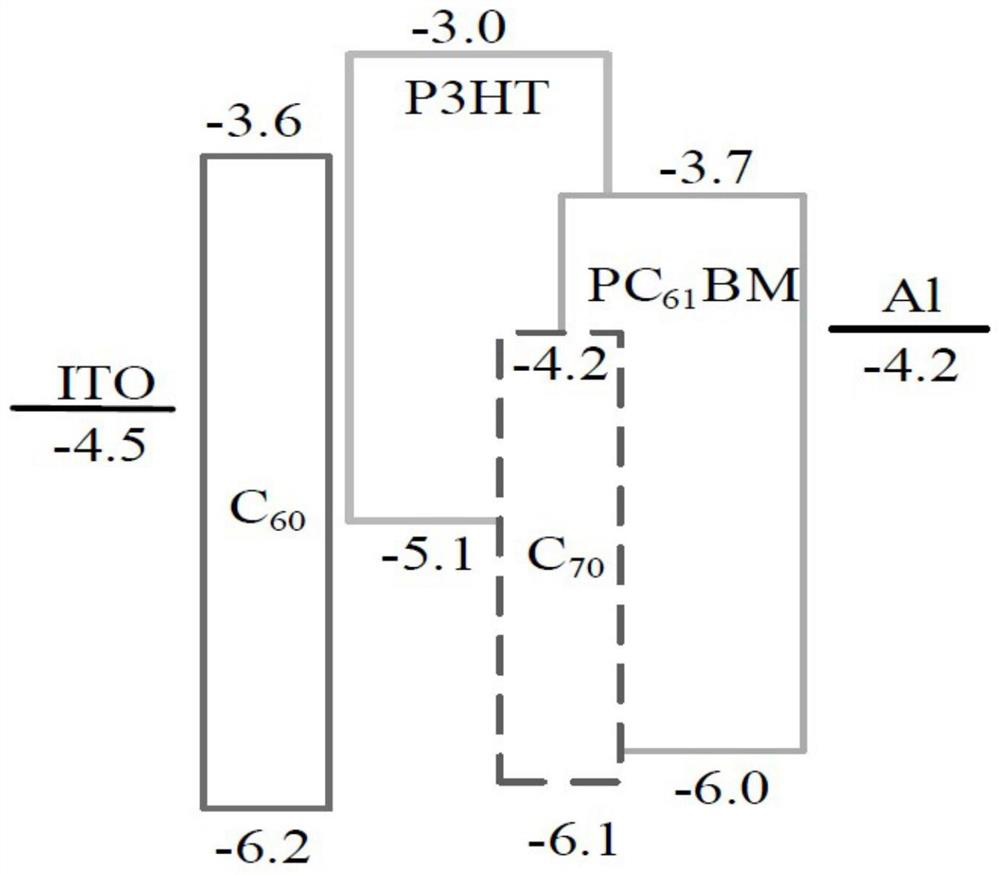

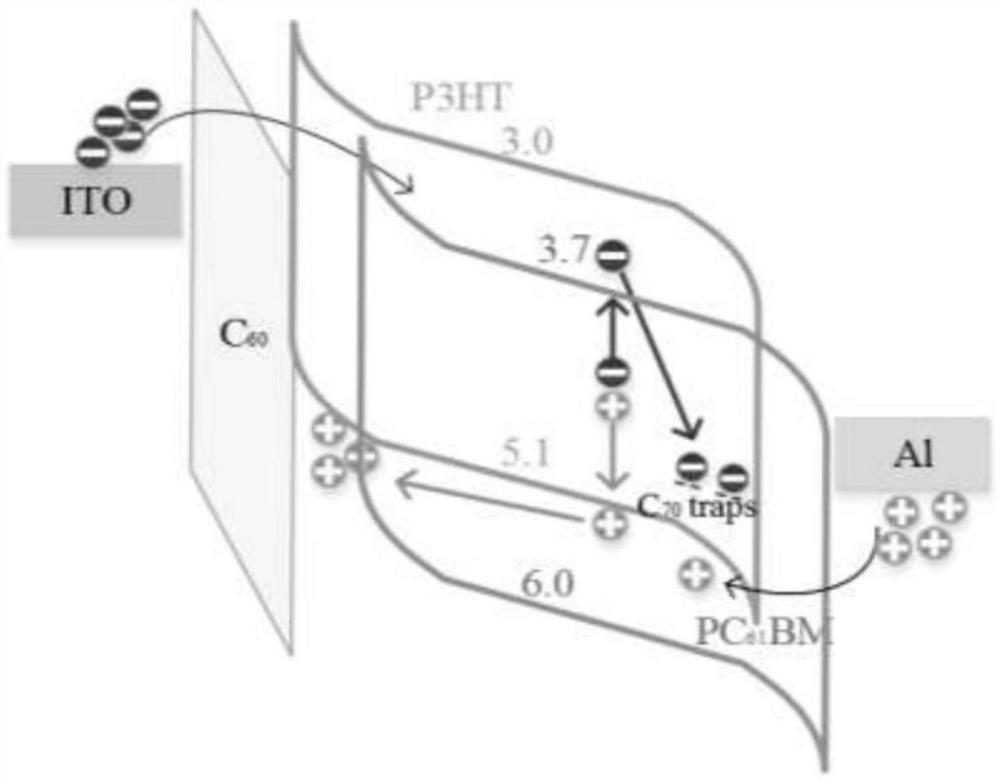

[0044] A method for preparing a double injection multiplied organic photodetector, comprising the following steps:

[0045] Step 1, first coating the ITO electrode layer 2 on the glass substrate 1, and then cleaning the glass substrate 1;

[0046] Specifically, first use deionized water to ultrasonically clean the glass substrate 1 for 15 minutes to 20 minutes, then use acetone to ultrasonically clean the glass substrate 1 for 15 minutes to 20 minutes, then use absolute ethanol to ultrasonically clean it for 15 minutes to 20 minutes, and blow it with pure nitrogen. dry or infrared drying, and finally use ultraviolet ozone to light-clean the glass substrate 1;

[0047] Step 2, vapor-deposit C on the glass substrate 1 treated in step 1 60 , forming an anode buffer layer 3;

[0048] Step 3, first connect P3HT, PC 61 BM, C 70 Dissolving in dichlorobenzene to form a mixed solution, spin coating the mixed solution on the surface of the anode buffer layer 3, and annealing the gla...

Embodiment 1

[0054] Step 1. First coat the ITO electrode layer 2 on the glass substrate 1, and then clean the glass substrate 1. First, use deionized water to ultrasonically clean the glass substrate 1 for 15 minutes, and then use acetone to clean the glass substrate 2. Ultrasonic cleaning for 16 minutes, then ultrasonic cleaning with absolute ethanol for 18 minutes, and drying with pure nitrogen or infrared drying, and finally optical cleaning of the glass substrate 1 with ultraviolet ozone;

[0055] Step 2. On the glass substrate 1 processed in step 1, a vacuum evaporation machine evaporates C with a thickness of 15 nm. 60 As an anode buffer layer 3;

[0056] Step 3, first connect P3HT, PC 61 BM, C 70 Dissolve in dichlorobenzene to form a mixed solution, spin coat the mixed solution on the anode buffer layer 3, and anneal the glass substrate 1 after spin coating to form an active layer 4 with a thickness of 150 nm;

[0057] Among them, P3HT: PC 61 BM: C 70 The mass ratio is 10:10:0....

Embodiment 2

[0061] Step 1. First coat the ITO electrode layer 2 on the glass substrate 1, and then clean the glass substrate 1. First, use deionized water to ultrasonically clean the glass substrate 1 for 16 minutes, and then use acetone to clean the glass substrate 1. Ultrasonic cleaning for 18 minutes, then ultrasonic cleaning for 18 minutes with absolute ethanol, and drying with pure nitrogen or infrared drying, and finally optical cleaning of the glass substrate 1 with ultraviolet ozone;

[0062] Step 2, on the glass substrate 1 processed by step 1, vacuum evaporation machine vapor deposition thickness is 10nm C 60 As an anode buffer layer 3;

[0063] Step 3, first connect P3HT, PC 61 BM, C 70 Dissolve in dichlorobenzene to form a mixed solution, spin coat the mixed solution on the anode buffer layer 3, and anneal the glass substrate 1 after spin coating to form an active layer 4 with a thickness of 190 nm;

[0064] Among them, P3HT: PC 61 BM: C 70 The mass ratio is 10:10:0.3, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com