Compound additive for preparing high-moisture silage as well as preparation method and application of compound additive

A compound additive and silage technology, which is applied in the preservation method, application and animal feed of animal feed raw materials, can solve the problems that feed raw materials affect the development of animal husbandry, affect the safety of feed, and affect the health of livestock, so as to reduce energy and Loss of Nutrients, Effects of Lowering Temperature and Improving Feed Intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

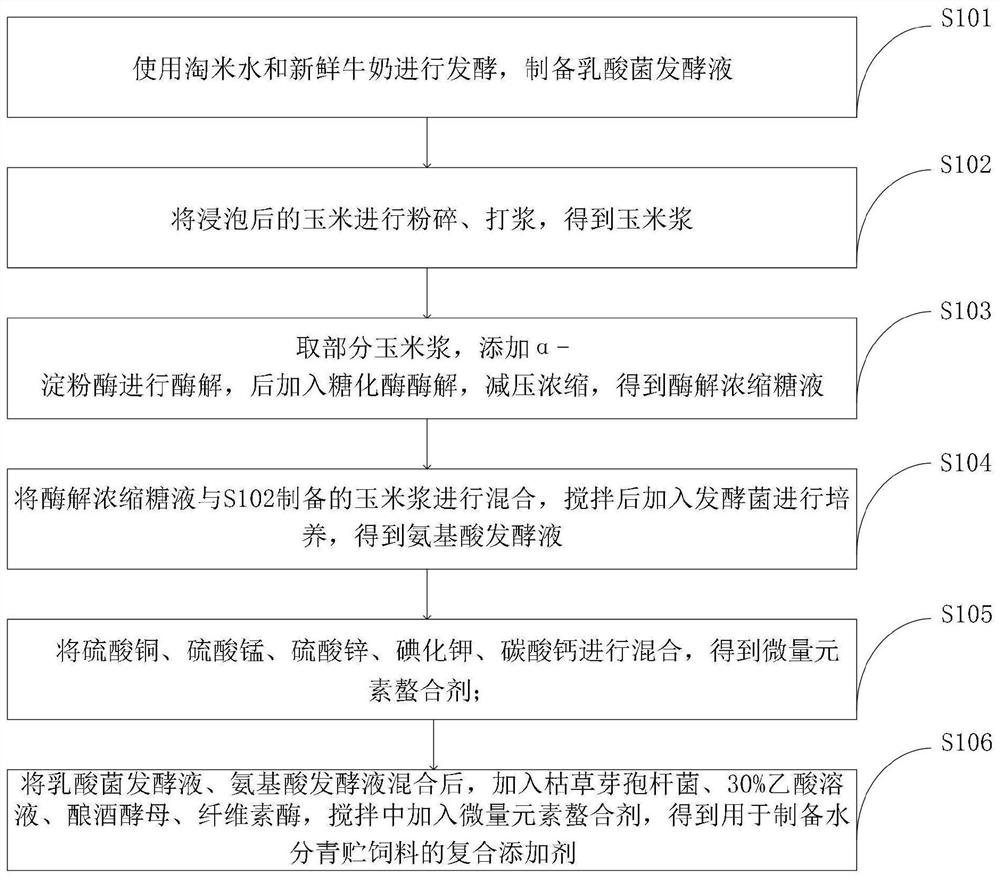

[0049] Such as figure 1 Shown, the preparation method for the compound additive that is used to prepare moisture silage that the embodiment of the present invention provides comprises the following steps:

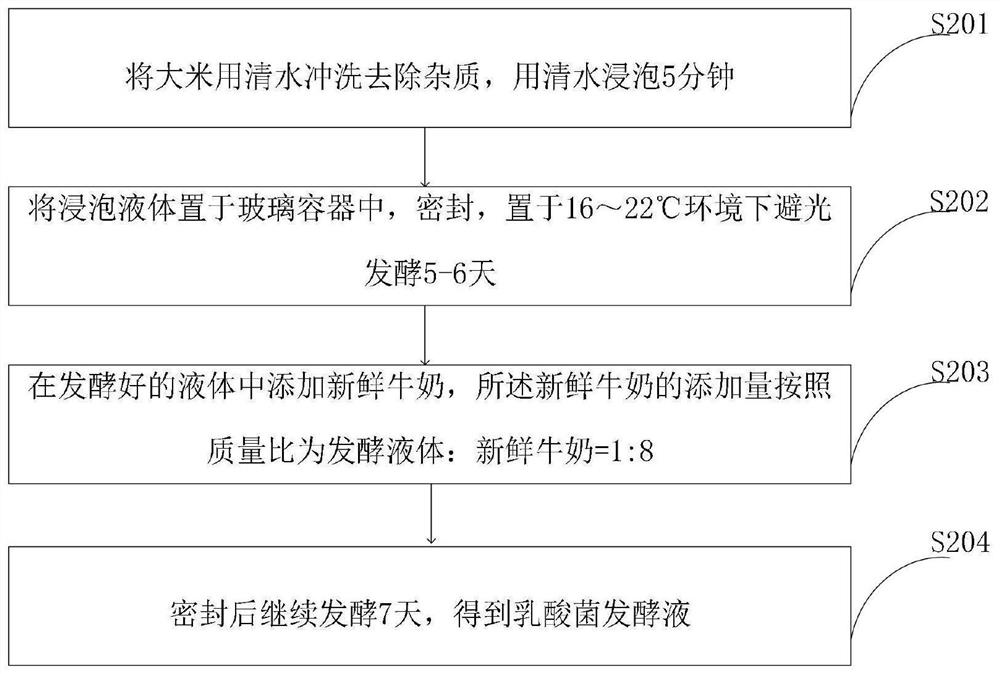

[0050] S101, using rice washing water and fresh milk for fermentation to prepare a lactic acid bacteria fermentation liquid;

[0051] S102, crushing and beating the soaked corn to obtain corn steep liquor;

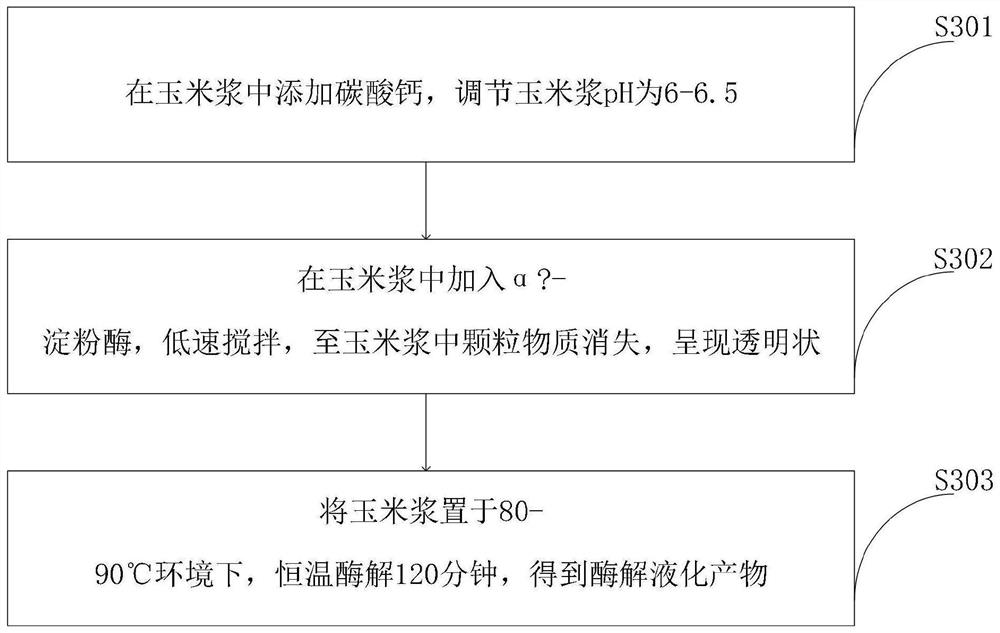

[0052] S103, taking part of the corn steep liquor, adding α-amylase for enzymolysis, then adding glucoamylase for enzymolysis, and concentrating under reduced pressure to obtain enzymolysis concentrated sugar solution;

[0053] S104, mixing the enzymatically hydrolyzed concentrated sugar liquid with the corn steep liquor prepared in S102, adding fermentation bacteria after stirring, and culturing to obtain an amino acid fermentation liquid;

[0054] S105, mixing copper sulfate, manganese sulfate, zinc sulfate, potassium iodide and calcium carbonate to obtain a trace e...

Embodiment 1

[0086] Use rice washing water and fresh milk for fermentation to prepare lactic acid bacteria fermentation broth;

[0087] Grinding and beating the soaked corn to obtain corn steep liquor; taking part of the corn steep liquor, adding α-amylase for enzymatic hydrolysis, and then adding glucoamylase for enzymatic hydrolysis, concentrating under reduced pressure to obtain enzymatic hydrolyzed concentrated sugar liquid; enzymatically hydrolyzed and concentrated The sugar solution is mixed with the corn steep liquor prepared in step 2, and after stirring, the fermentation bacteria are added for cultivation to obtain the amino acid fermentation liquid;

[0088] After mixing the lactic acid bacteria fermentation liquid and the amino acid fermentation liquid, add Bacillus subtilis, 30% acetic acid solution, Saccharomyces cerevisiae, and cellulase, and add copper sulfate, manganese sulfate, zinc sulfate, potassium iodide, and calcium carbonate during stirring to obtain Compound additiv...

Embodiment 2

[0090] Drying the rice straw to a water content of 60-65%, and pulverizing it in a pulverizer to obtain rice straw powder; drying the corn straw to a water content of 65-70%, and putting it in a pulverizer pulverized to obtain coarse grains of corn stalks;

[0091] The compound additive for preparing high-moisture silage prepared in Example 1 is mixed with water according to a volume ratio of 1:60, and after stirring, the high-moisture silage spraying agent is obtained;

[0092] Mix corn straw granules and rice straw powder, spray water silage spraying agent, control the water after mixing at 60%-70%, strictly seal and compact, ferment for 7-10 days; spray again, when silage fermentation material When there is a sour smell or wine smell, it means that it has matured and can be fed directly.

[0093] Table 1: Changes in pH value of silage during fermentation:

[0094] number of days 1 2 5 10 20 30 pH value 6.0 5.9 4.9 4.5 4.3 4.2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com