Waterborne polyurethane resin as well as preparation method and application thereof

A water-based polyurethane and resin technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor stone chip resistance, achieve excellent stone chip resistance, reduce VOC, and reduce environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

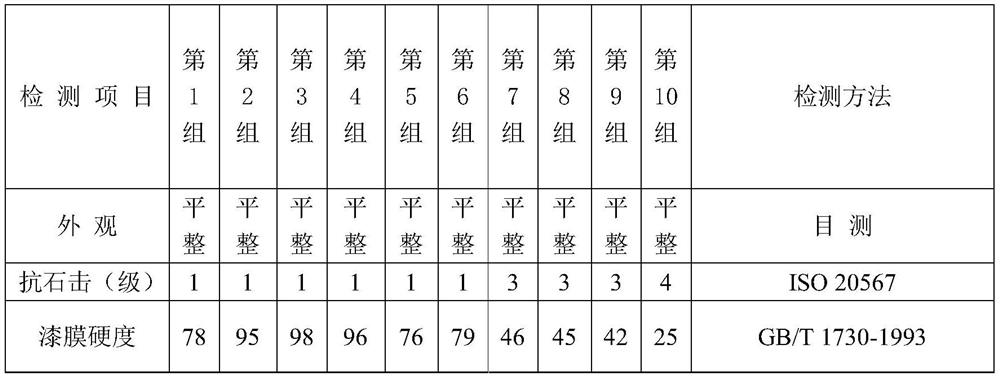

Examples

Embodiment 1

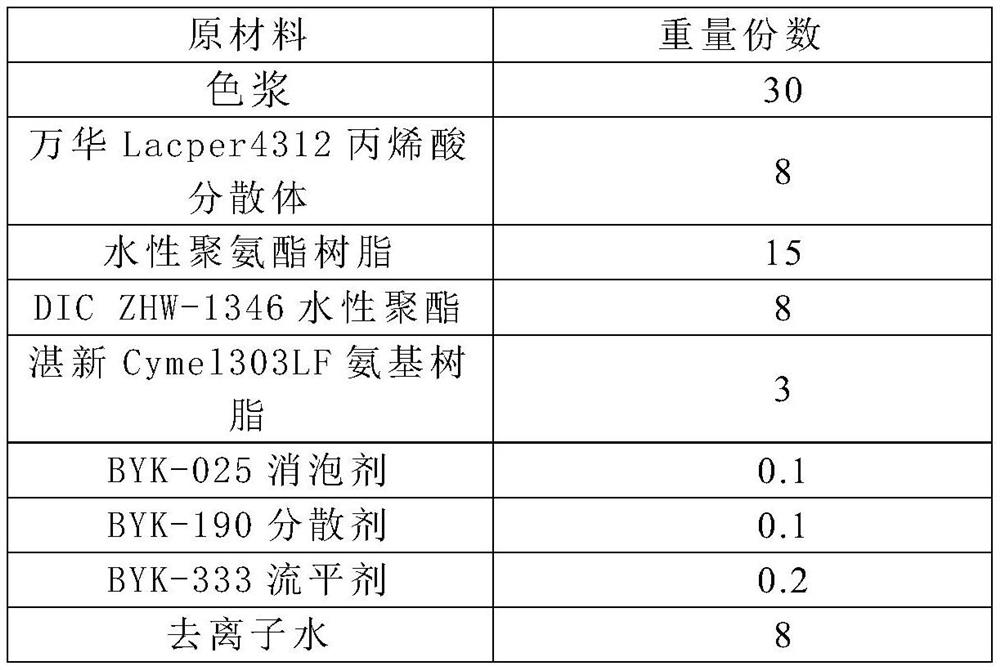

[0033] A kind of aqueous polyurethane resin, comprises the raw material of following parts by weight:

[0034] Polycarbonate diol: 20 parts;

[0035] Dimethylolbutyric acid: 5 parts;

[0036] Isophorone diisocyanate: 20 parts;

[0037] Pentaerythritol: 4 parts;

[0038] 1.2-Propanediol: 5 parts;

[0039] Tin dilaurate: 1 part;

[0040] Triethylamine: 4 parts.

[0041] Its preparation method comprises the following steps:

[0042] (1) Under nitrogen protection, 20 parts of polycarbonate diol, 5 parts of dimethylol butyric acid, 20 parts of isophorone diisocyanate, 1 part of tin dilaurate are added to the reactor, and the temperature is raised to 80 ℃, reaction 2h;

[0043] (2) Add 4 parts of pentaerythritol, further react for 2 hours, then add 5 parts of 1.2-propylene glycol, stir and react for 1 hour, cool down, add 4 parts of triethylamine for neutralization reaction;

[0044] (3) Add 112 parts of deionized water under high shear conditions and stir for 2 hours to obt...

Embodiment 2

[0046] A kind of aqueous polyurethane resin, comprises the raw material of following parts by weight:

[0047] Polyester diol: 25 parts;

[0048] Sodium 1,4-dihydroxy-2-butanesulfonate: 3 parts;

[0049] Diphenylmethane diisocyanate: 15 parts;

[0050] Hexamethylene diisocyanate: 5 parts;

[0051] Trimethylolpropane: 3 parts;

[0052] Palm oil: 6 parts;

[0053] 1,4-butanediol: 6 parts;

[0054] Bismuth laurate: 1.5 parts;

[0055] N,N`-Dimethylethanolamine: 6 parts.

[0056] Its preparation method comprises the following steps:

[0057] (1) Under the protection of nitrogen, 25 parts of polyester diol, 3 parts of 1,4-dihydroxy-2-butane sulfonate sodium, 15 parts of diphenylmethane diisocyanate, 5 parts of hexamethylene diisocyanate 1.5 parts of bismuth laurate were added to the reactor, the temperature was raised to 90°C, and the reaction was carried out for 3 hours;

[0058] (2) Add 3 parts of trimethylolpropane and 6 parts of palm oil, further react for 3 hours, the...

Embodiment 3

[0061] A kind of aqueous polyurethane resin, comprises the raw material of following parts by weight:

[0062] Polyether diol: 30 parts;

[0063] Sodium 1,4-dihydroxy-2-butanesulfonate: 2 parts;

[0064] Cyclohexane dimethylene diisocyanate: 25 parts;

[0065] Trimethylolpropane: 2 parts;

[0066] Palm oil: 5 parts;

[0067] Hexamethylenediamine: 3 parts;

[0068] Tin protochloride: 1.2 parts;

[0069] N,N`-diisopropylethylamine: 6 parts.

[0070] Its preparation method comprises the following steps:

[0071] (1) Under the protection of nitrogen, 30 parts of polyether diol, 2 parts of 1,4-dihydroxy-2-butane sulfonate sodium, 25 parts of cyclohexane dimethylene diisocyanate, 1.2 parts of chlorinated Add tin into the reactor, raise the temperature to 75°C, and react for 4 hours;

[0072] (2) Add 2 parts of trimethylolpropane and 5 parts of palm oil, further react for 2 hours, then add 3 parts of hexamethylenediamine, stir and react for 2 hours, cool down, add 6 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com