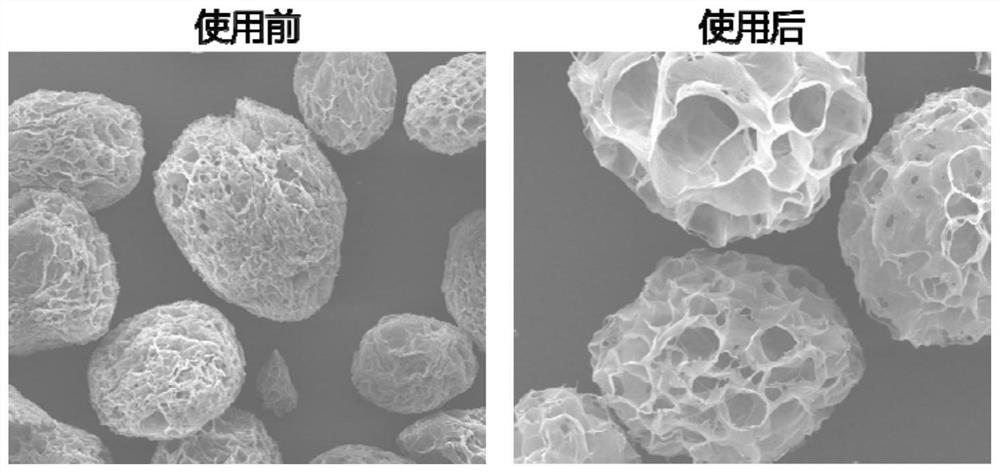

Three-dimensional porous micro-carrier scaffold and method for preparing scaffold by adopting ionic additive

An additive preparation, three-dimensional porous technology, applied in prosthetics, medical science, etc., can solve the problems of inconsistent density, inability to exist in large quantities, and uneven pore size distribution, etc., and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Preparation of aqueous phase solution:

[0048] 1) The aqueous solution involved contains: artificially synthesized biomaterials and / or natural biomaterials, ionic pore-forming additives and curing agents

[0049] Weigh a certain amount of bovine collagen and chitin powder, the total amount is 100%, the unit is g / mL, and the mass volume fraction of 1% collagen powder + 1% chitin is fully dissolved in deionized water. Weigh the ionic porogenic additive sodium bisulfate, add it into the premix and stir (at a speed of 300rmp), and configure it to a final concentration of 0.5% w / v.

[0050] (2) Organic phase solution configuration:

[0051] Measure chloroform and petroleum ether at a volume ratio of 1:1 and mix evenly at 700 rpm for 1 hour, then add Tween 20 at a final concentration of 5% v / v (ml / ml), and continue stirring at 700 rpm for 1 hour. Transfer to -30°C refrigerator to fully cool down and pre-cool for 10 hours.

[0052] (3) Emulsion preparation:

[0053] 1...

Embodiment 2

[0067] (1) Premix solution preparation:

[0068] Weigh a certain amount of hyaluronic acid and gelatin powder, the total amount is 100%, the unit is g / mL, and the mass volume fraction of 0.01% hyaluronic acid powder + 3% gelatin powder is fully dissolved in deionized water. Weigh the ionic porogenic additive potassium sulfate, add it into the premix and stir (300rmp) to prepare a final concentration of 0.5%.

[0069] (2) Organic phase solution configuration:

[0070] Measure carbon tetrachloride and petroleum ether at a volume ratio of 1:4 and mix evenly at 1000 rpm for 1 hour, then add a final concentration of 8% v / v Tween 80, and continue stirring at 700 rpm for 1 hour. After fully cooling, transfer to -30°C refrigerator to fully cool down and pre-cool for 16 hours.

[0071] (3) Emulsion preparation:

[0072] 1) adding ethanol to a low-temperature refrigerator, and using the low-temperature refrigerator to cool to -30 degrees Celsius;

[0073] 2) Add 0.5% v / v (ml / ml) for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com