Semi-fluid smooth texture residue-free full-nutrition food and preparation method thereof

A full-nutrition, semi-fluid technology, applied in the field of special dietary food, can solve the problems of poor oral experience, poor taste, low compliance, etc., to avoid flatulence and diarrhea, reduce the production of feces, and facilitate digestion and absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

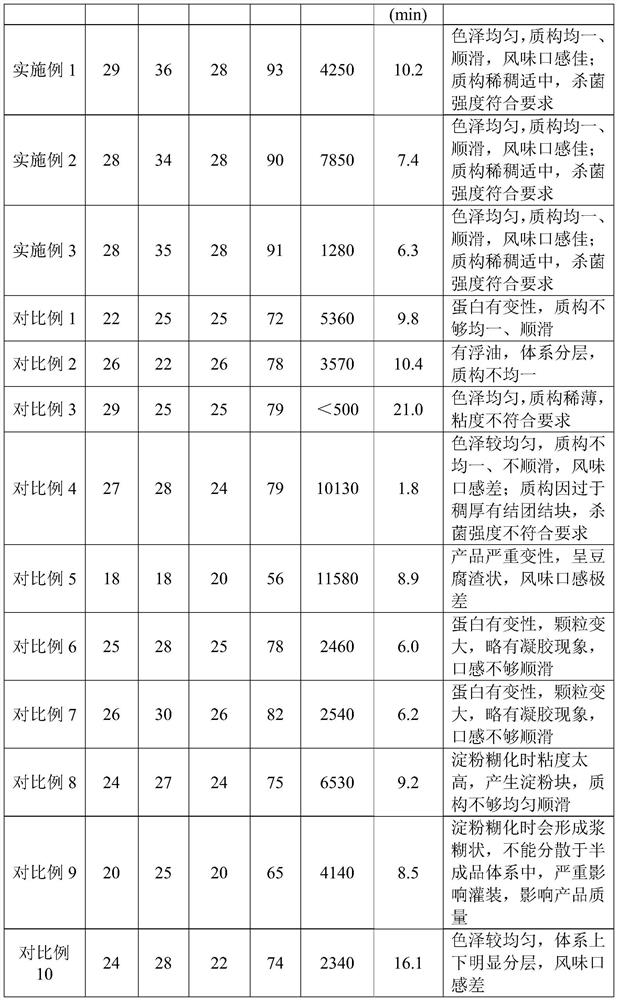

Embodiment 1

[0066] A kind of semi-fluid smooth texture non-dregs full nutritional food, including the following raw materials in mass fraction: concentrated whey protein 6%, concentrated milk protein 3%, maltodextrin 12%, cornstarch 3%, white sugar 6%, MCT oil 1%, soybean oil 2%, cream 7%, multivitamin 0.024% (vitamin A 800μg / Kg, vitamin D 20μg / Kg, vitamin B 1 1.2mg / Kg, Vitamin B 2 1.2mg / Kg, Vitamin C 200mg / Kg, Vitamin E 20mg / Kg, Vitamin B 6 1.2mg / Kg, Vitamin B 12 1.2μg / Kg, nicotinamide 12mg / Kg), complex minerals 0.035% (ferric pyrophosphate 0.005%, zinc gluconate 0.005%, selenium-enriched yeast 0.01%, magnesium carbonate 0.015%), taurine 0.02%, essence 0.2 %, the balance is water.

[0067] Among them, the ratio of the total mass of whey protein and milk protein to the mass of corn starch is 3:1; the ratio of the total mass of whey protein to the total mass of casein is about 2.75:1; the mass ratio of maltodextrin to corn starch It is 4:1.

[0068] Prepared by the following steps:...

Embodiment 2

[0076] A kind of semi-fluid smooth texture non-dregs full nutritional food, including the following raw materials in mass fraction: 3% whey protein isolate, 3% sodium caseinate, 8% maltodextrin, 4% cornstarch, 3% white sugar , MCT oil 1%, soybean oil 2%, multivitamin 0.020% (vitamin A 600μg / Kg, vitamin D 30μg / Kg, vitamin B11.4mg / Kg, vitamin B2 1.0mg / Kg, vitamin C 160mg / Kg, vitamin E 28mg / Kg, vitamin B6 1.0mg / Kg, vitamin B12 1.0μg / Kg, nicotinamide 8mg / Kg), complex minerals 0.042% (iron pyrophosphate 0.006%, zinc gluconate 0.006%, selenium-enriched yeast 0.012%, carbonic acid magnesium 0.018%), taurine 0.03%, essence 0.3%, and the balance is water.

[0077] Among them, the ratio of the total mass of whey protein and milk protein to the mass of corn starch is 1.5:1; the ratio of the total mass of whey protein to the total mass of casein is about 1:1; the mass ratio of maltodextrin to corn starch It is 2:1.

[0078] Prepared by the following steps:

[0079] (1) shearing and dispe...

Embodiment 3

[0086] A kind of semi-fluid smooth texture non-dregs-free complete nutritional food, including the following raw materials in mass fractions: concentrated whey protein 6%, micellar casein 6%, maltodextrin 20%, corn starch 1.2%, white sugar 0% , coconut oil 3%, soybean oil 3%, multivitamin 0.024% (vitamin A 800μg / Kg, vitamin D 20μg / Kg, vitamin B 1 1.2mg / Kg, Vitamin B 2 1.2mg / Kg, Vitamin C 200mg / Kg, Vitamin E 20mg / Kg, Vitamin B 6 1.2mg / Kg, Vitamin B 12 1.2μg / Kg, nicotinamide 12mg / Kg), complex minerals 0.035% (ferric pyrophosphate 0.005%, zinc gluconate 0.005%, selenium-enriched yeast 0.01%, magnesium carbonate 0.015%), taurine 0.02%, essence 0.2 %, the balance is water.

[0087] Among them, the ratio of the total mass of whey protein and milk protein to the mass of corn starch is 10:1; the ratio of the total mass of whey protein to the total mass of casein is about 1:1; the mass ratio of maltodextrin to corn starch About 16.7:1.

[0088] Prepared by the following steps:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com