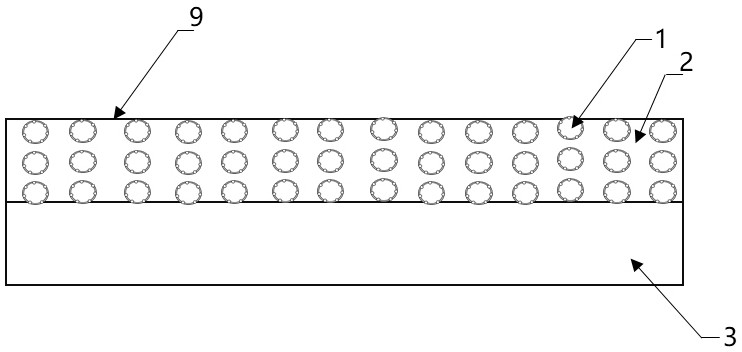

Foldable antibacterial transparent hardening layer, antibacterial flexible cover plate and preparation method

A technology of hardened layer and flexible cover, which is applied in the field of antibacterial flexible cover plate and its preparation, and antibacterial transparent hardened layer, which can solve the problems of not cleaning mobile phones and aggravating bacterial reproduction, etc., to achieve inhibition of bacterial growth and reproduction, strong sterilizing activity, The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] This embodiment provides a method for preparing an antibacterial flexible cover, the steps are:

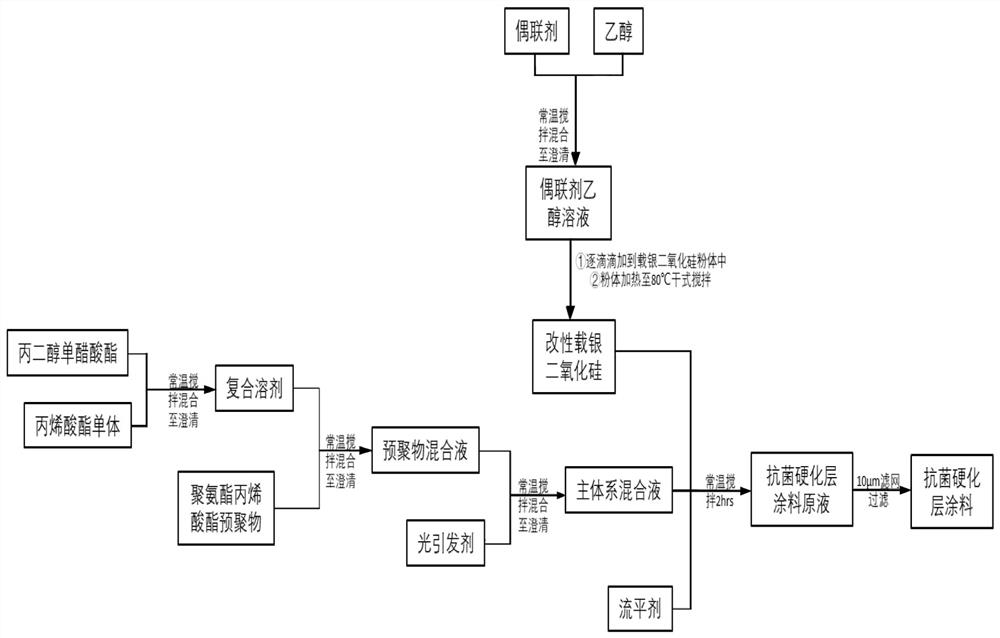

[0066] Step 1, prepare UV type antibacterial hardening coating according to the following method:

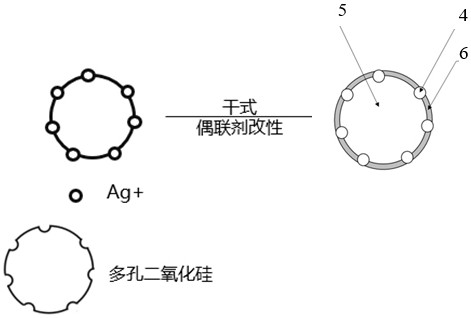

[0067] Add 40 g of coupling agent KH-560 and 250 g of ethanol into a 1L beaker, stir at 300 rpm for 0.5 hour at room temperature, and prepare a solution of KH-560 for use. Add 1000g of silver-loaded silica (4% silver loading) into the dry high-speed stirred tank A, set the temperature of the stirred tank to 80°C, and stir at 1-2 drops / second at a high speed of 1200rpm Add the KH-560 solution dropwise into the stirring tank. After the KH-560 solution is added dropwise, continue to stir at a high speed for 30 minutes, and wait for the stirring tank A to cool down to prepare the modified silver-loaded silica.

[0068] Add 400g of reactive diluent 1,4-butanediol diacrylate BDDA and 200g of diluent propylene glycol monoacetate into stirring tank B, and stir at 300rpm for 10min a...

Embodiment 2

[0079] The difference between this embodiment and Example 1 is that the polyurethane acrylate prepolymer used in this embodiment adopts aliphatic diisocyanate and polyether polyol to prepare the polyurethane prepolymer, then lowers the temperature of the polyurethane prepolymer solution and The temperature is controlled between 40-50° C., and 0.1 mol of acrylate compound dissolved with 0.4 mol of hydroquinone is added therein under stirring to obtain a polyurethane acrylate prepolymer.

[0080] Due to the weak interaction between molecular chains and the low crystallinity of the reaction product, the polyether structure has good optical properties, and the polyether structure has good aging resistance and flexibility; aliphatic diisocyanate has light aging resistance, excellent weather resistance and no yellowing. Change. Therefore, the prepared antibacterial transparent hardened layer has good optical properties, excellent aging resistance and good flexibility, and is more su...

Embodiment 3

[0082] The difference between this embodiment and Example 1 is: in the silver-loaded silica, the silver load is 3%; when preparing UV type antibacterial hardening paint, the reactive diluent multifunctional acrylate used is HDDA (1,6-hexyl diol diacrylate); in addition, the transparent flexible substrate under the antibacterial flexible cover is COP with a thickness of 15 μm.

[0083] The antibacterial flexible cover of Example 1 was tested in a hundred grids. The adhesion of the antibacterial hardened layer on the COC was 5B (the highest level of adhesion), and the overall transmittance of the antibacterial flexible cover was about 92%. The cover plate can be bent more than 50,000 times when the bending radius is 1-1.5 mm; the antibacterial performance of the antibacterial flexible cover plate shows that it can sterilize Pseudomonas aeruginosa, Staphylococcus aureus, Escherichia coli and Bacillus subtilis rate reached 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bending radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com