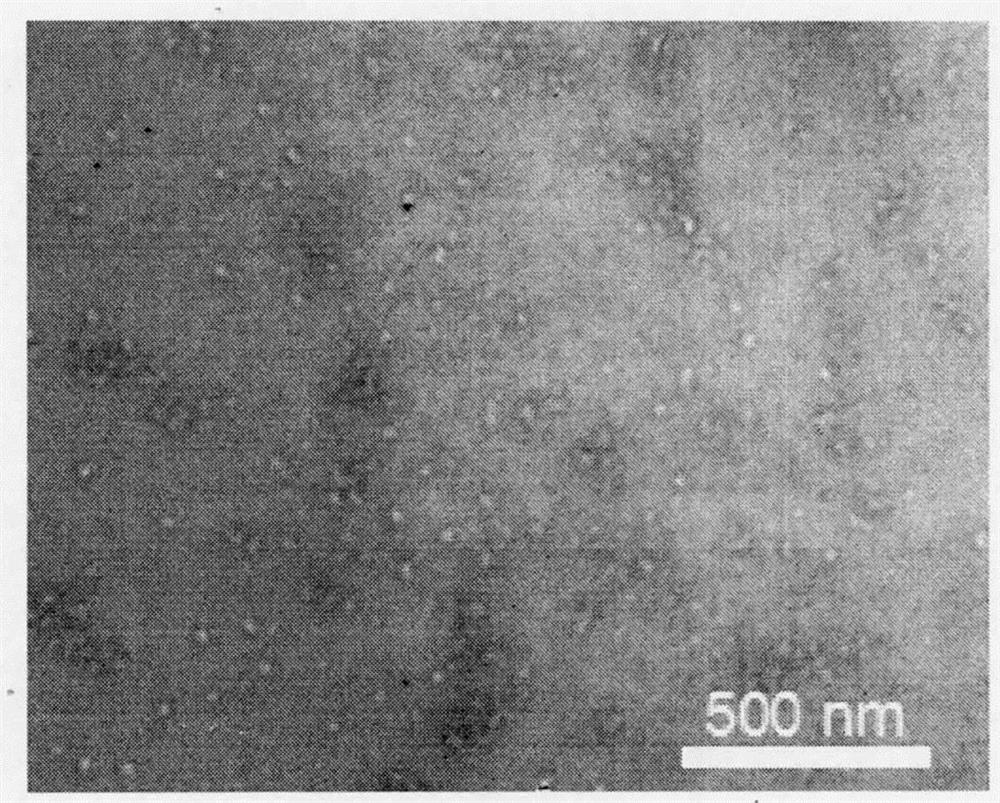

Polypyrrole porous hollow nano microsphere and preparation method and application thereof

A technology of nano-microspheres and polypyrrole, applied in the field of nanotechnology, can solve problems such as poor application in industrial production, single structure of polypyrrole, toxic and harmful chemicals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

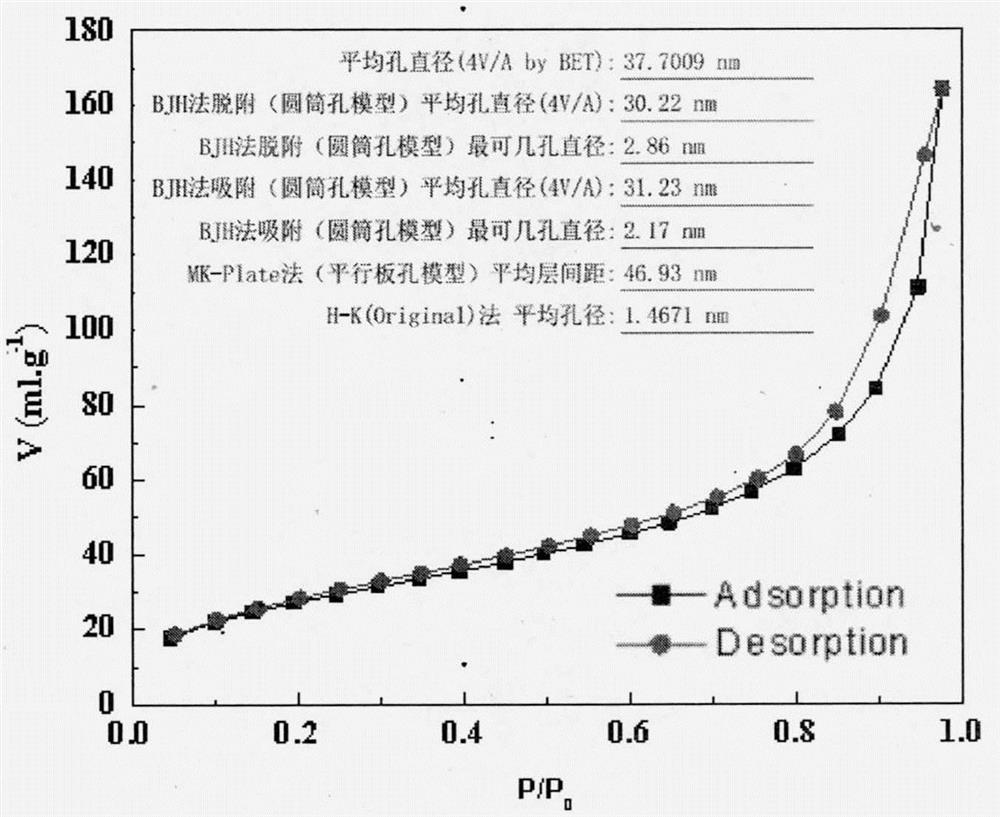

Method used

Image

Examples

Embodiment 1

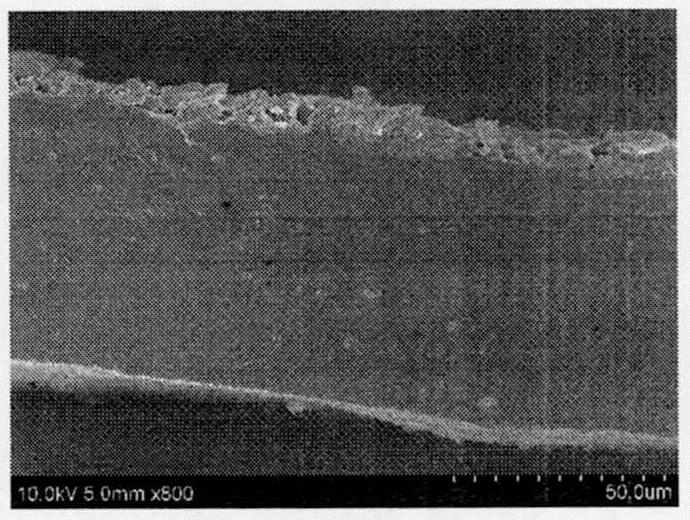

[0014] Dissolve a certain amount of Pebax1657 in a mixed solution of ethanol / water (70wt% / 30wt%), heat at 80°C for two hours, add a certain amount of polypyrrole porous hollow nanospheres to the mixed solution, and disperse evenly with ultrasonic stirring. The mixed solution was poured into a polytetrafluoroethylene mold, left at room temperature for 24 hours, and vacuum-dried in a vacuum oven at 45° C. for 24 hours.

[0015] Table 1 Permeation separation performance of Pebax / polypyrrole porous hollow nanosphere mixed matrix membrane

[0016]

Embodiment 2

[0018] Polyethylene glycol methacrylate (PEGMEA) was used as a monomer, pentaerythritol triacrylate (PETA) was used as a crosslinking agent, polypyrrole porous hollow nanospheres were used as a filling material, and a certain amount of photoinitiator was added. The mixed solution was poured into a brown bottle and ultrasonically dispersed evenly, placed between two glass plates, and the thickness was controlled by a copper wire to prepare a series of gas separation membranes. Carry out gas permeation performance test to the film and find that, N 2 、CH 4 , CO 2 Compared with the original membrane, the permeation performance is increased by about 2 times, and its selectivity remains unchanged.

Embodiment 3

[0020] Weigh a certain proportion of polydimethylsiloxane and its crosslinking agent and n-heptane, stir evenly, then add polypyrrole porous hollow nano-microspheres, stir and ultrasonically, and coat it on the PVDF porous bottom membrane . The coated film was placed in a fume hood to volatilize naturally for several hours, and then placed in an oven for thermal crosslinking. The mass ratio of polypyrrole porous hollow nano microspheres to polydimethylsiloxane is 1%-5%, and the obtained membrane is dried and used for pervaporation. Pervaporation test conditions: the vacuum on the downstream side is 5mmHg absolute negative pressure, and the cold well is condensed and collected; the operating temperature on the upstream side is 40°C, and the feed liquid is 5wt% ethanol aqueous solution (mass fraction). Its performance is shown in Table 2.

[0021] Table 2 Ethanol separation performance of polydimethylsiloxane / polypyrrole porous hollow nanosphere mixed matrix membrane

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com