Catalytic ozonation-based pretreatment method for acid wastewater containing water-soluble polymer hard to degrade

A water-soluble polymer, ozonation technology, applied in the fields of oxidized water/sewage treatment, water/sewage treatment, special compound water treatment, etc., can solve the problems of unachieved degradation of pollutants, harsh treatment conditions, and low treatment efficiency. , to achieve the effect of easy operation, good stability and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

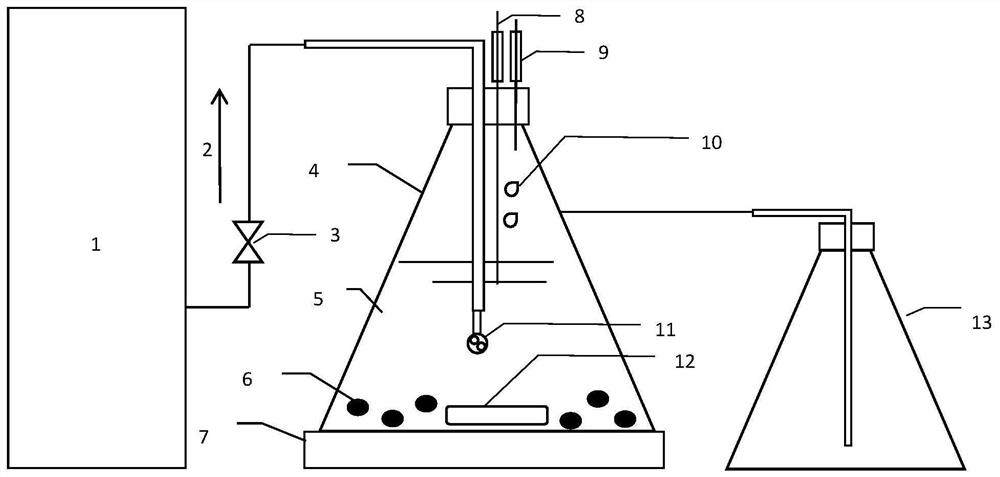

[0019] Experimental device such as figure 1 As shown, the reaction system consists of an ozone generator 1, a gas inlet device 3 (rubber tube with a valve), an Erlenmeyer flask reactor 4 equipped with waste water to be treated 5, a solid catalyst 6 and a magnetic rotor 12, and a glass aeration head 11. Hydrogen peroxide dripping device 9, sampling device 8, magnetic stirrer 7 and tail gas absorbing device 13 are composed; ozone 2 produced by ozone generator 1 using oxygen as a gas source enters the Erlenmeyer flask reactor through gas inlet device 3 4; the end of the gas inlet device 3 is provided with an aeration device with a glass aeration head 11, and the glass aeration head 11 is immersed in the waste water 5 to be treated; a hydrogen peroxide dripping device is installed on the top of the conical flask reactor 4 9 and sampling device 8; Erlenmeyer flask reactor 4 is seated on the magnetic stirrer 7; after the waste water 5 to be treated in the Erlenmeyer flask reactor 4 ...

Embodiment 2

[0030] The PVC centrifugal mother liquor discharged from the PVC production and polymerization stage in a chlor-alkali factory was used for experiments. The initial PVA concentration of the wastewater was 3mg / L, the COD concentration was 190mg / L, and the initial pH was 5.3. After processing according to the method described in Example 1, the removal rate of PVA in the water sample is close to 100%, and the reaction time is extended to 2h, and the removal rate of COD is about 80%.

Embodiment 3

[0032] PVA particles with a degree of polymerization of 1750±50 were dissolved in distilled water to prepare simulated wastewater, and mixed with the collected PVC centrifuge mother liquor discharged from the PVC production polymerization stage in a chlor-alkali factory for experiments. The initial PVA concentration of the mixed wastewater was 23mg / L, the COD concentration is 250mg / L, and the initial pH is adjusted to 3. After treatment according to the method described in Example 1, the removal rate of PVA in the water sample was close to 100%, and the reaction time was extended to 2 hours, and the removal rate of COD was about 72%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com