Continuous synthesis method and application of sulfonated keto-aldehyde condensation compound

A technology for sulfonated ketone-aldehyde condensate and sulfonated acetone, which is applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, chemical/physical processes, etc. It is easy to generate by-products and other problems, so as to achieve the effect of simple preparation method, convenient operation and continuous safe production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

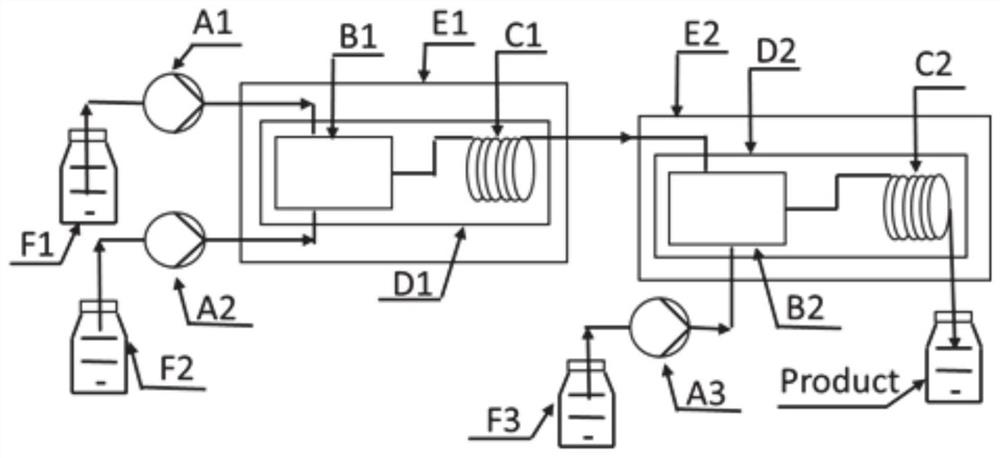

[0072] The sulfonation reaction in embodiment 1,2,3,4,5 takes sodium p-toluenesulfonate, amino-substituted naphthalenesulfonate sodium, sodium pyrosulfite solution, sodium sulfite and sodium lignosulfonate as sulfonating agent respectively, with The sulfonated acetone that generates in the first step reaction is that raw material carries out condensation reaction; Embodiment 1,2 is to carry out sulfonated reaction with acetone, acetophenone as raw material in continuous tank reactor; Embodiment 3,4 is to carry out sulfonated reaction in tube Formaldehyde and acetaldehyde are used as raw materials for condensation reaction in the reactor. Example 5 is a condensation reaction of sulfonated acetone in a microstructure reactor using an aqueous solution of sodium hydroxide (the mass ratio of water to sodium hydroxide is 5:1) as a catalyst.

[0073] The present invention is further explained and illustrated by the following examples, but does not constitute a limitation of the prese...

Embodiment 2

[0080] The acetophenone solution and the amino-substituted naphthalenesulfonate sodium solution are introduced into a volume of 10m 3 In the continuous stirred tank reactor, the ratio of acetophenone solution and amino-substituted naphthalene sulfonate is 1:1.5, and the generated sulfonated acetophenone solution and formaldehyde are respectively passed into another continuous stirred tank reactor, and the temperature is controlled At 0°C, the stirring speed is 120r / min, the average residence time is 160min, the reaction product is collected at the outlet, the product solution is neutralized, dried by rotary evaporation, ethanol is precipitated, dried and ground to obtain a substituted naphthalenesulfonated acetophenone formaldehyde polycondensate, Its solids content is 28%.

Embodiment 3

[0082] The sodium sulfite solution and acetone are pumped into a tubular reactor with a temperature of 20°C, a diameter of 100mm, and a length of 5m by a liquid chromatography pump at an equivalent ratio of 1:3. The residence time of the material is 10min, and the resulting The sulfonated acetone solution and the formaldehyde solution were respectively passed into another tubular reactor, the temperature was controlled at 90°C, and the average residence time was 20 minutes. The solids content was 35%.

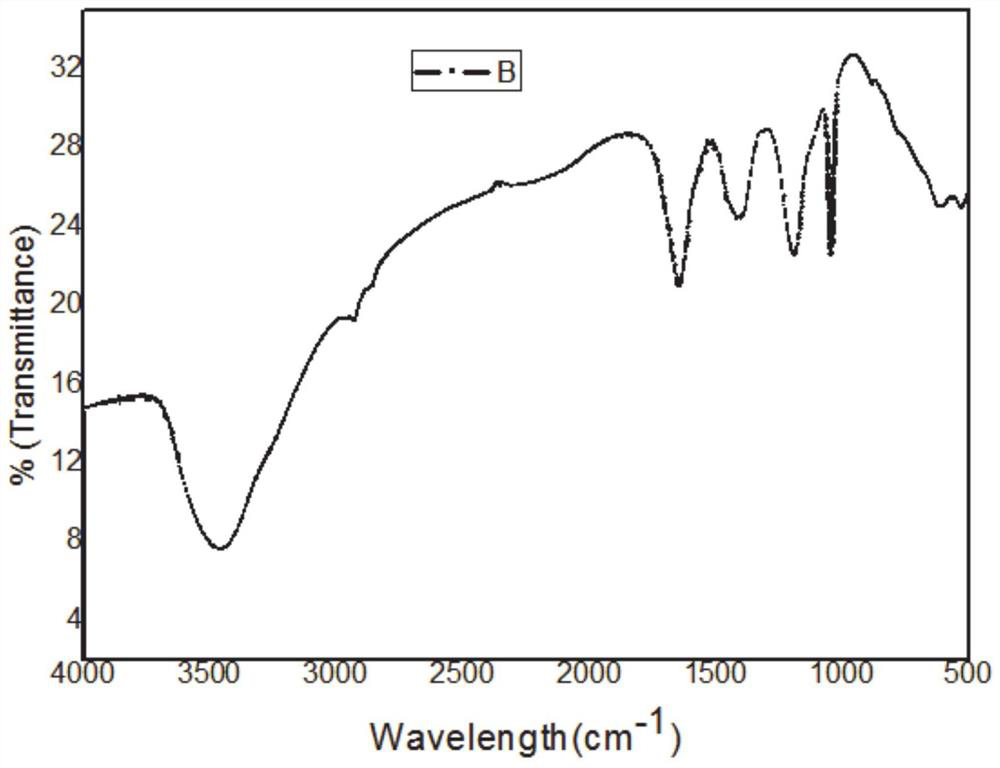

[0083] From figure 2 It can be seen from the spectrum that 3425.5cm is the stretching vibration absorption peak of the hydroxyl group; 2923.2cm is the stretching vibration peak of the C-H bond on the aliphatic molecular chain, and 2852.5cm is the CH 3 1619.6cm is the stretching vibration absorption peak of the carbonyl group; 1449.4cm is the asymmetric deformation vibration absorption peak of the methyl group; 1180 and 1045cm are -SO 3 The stretching vibration peak of alkyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com