Method for preparing pure calcium sulfate whiskers from carbide slag modified phosphogypsum

A technology of phosphogypsum and calcium carbide slag, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of large solid-liquid ratio, waste, underutilization of resources, etc., and achieve the effect of stable concentration and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

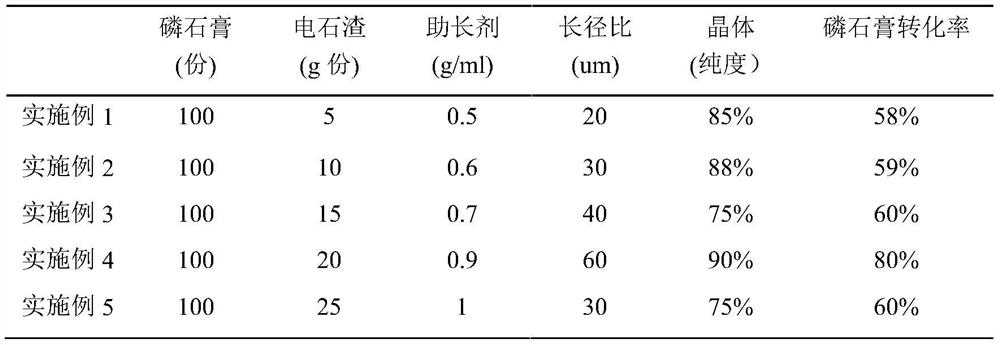

Embodiment 1

[0049] The preparation steps are as follows:

[0050] 1. First, take 100 parts of phosphogypsum powder passed through a 0.075mm square hole sieve, then take 5 parts of carbide slag powder, and stir in a mixer for 10 minutes to obtain a powder mixture.

[0051] 2. Take 100 parts of the powder mixture, add 55 parts of n-hexane and water at a ratio of 1:1, add 0.1 part of citric acid, 0.1 part of polycarboxylate superplasticizer, add grinding media, and put it into the grinder , grind for 1 hour, and sieve out the grinding medium to obtain a slurry.

[0052] 3. Take 100 parts of the slurry, add 0.5 parts of magnesium chloride, stir evenly, then transfer to a high-pressure reactor, control the temperature at 80 degrees Celsius, and after 2 hours of reaction time, treat with 1 part of ethanol and centrifuge to obtain a precipitate. Washing was repeated 3 times, and then freeze-dried to obtain anhydrous calcium sulfate whiskers.

Embodiment 2

[0054] The preparation steps are as follows:

[0055] 1. First, take 100 parts of phosphogypsum powder passed through a 0.075mm square hole sieve, then take 10 parts of calcium carbide slag powder, and stir in a mixer for 10 minutes to obtain a powder mixture.

[0056] 2. Take 100 parts of the powder mixture, add 110 parts of cyclohexane and water at a ratio of 1:1, add 0.15 parts of animal protein, 0.2 parts of naphthalene-based water reducer, add grinding media, and put it into the grinder , grind for 1.2 hours, and sieve out the grinding medium to obtain a slurry.

[0057] 3. Take 100 parts of the slurry, add 0.6 parts of sodium citrate, stir evenly, then transfer to a high-pressure reactor, control the temperature at 80 degrees Celsius, and after 2.5 hours of reaction time, treat with 1 part of ethanol and centrifuge to obtain the precipitate . Washing was repeated 3 times, and then freeze-dried to obtain anhydrous calcium sulfate whiskers.

Embodiment 3

[0059] 1. First, take 100 parts of phosphogypsum powder passed through a 0.075mm square hole sieve, then take 15 parts of carbide slag powder, and stir in a mixer for 10 minutes to obtain a powder mixture.

[0060] 2. Take 100 parts of the powder mixture, add 165 parts of chloroform and water at a ratio of 1:1, add 0.2 parts of sodium tripolyphosphate, 0.3 parts of naphthalene-based water reducer, add grinding media, and put it into the grinder , grind for 1.5 hours, and sieve out the grinding medium to obtain a slurry.

[0061] 3. Take 100 parts of the slurry, add 0.7 parts of sodium citrate, stir evenly, then transfer to a high-pressure reactor, control the temperature at 85 degrees Celsius, and after a reaction time of 3 hours, treat with 2 parts of ethanol and centrifuge to obtain a precipitate. Washing was repeated 3 times, and then freeze-dried to obtain anhydrous calcium sulfate whiskers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com