Summer delayed coagulation type high-performance structural adhesive and preparation method thereof

A high-performance, structural adhesive technology, used in the field of bridge structural adhesives, can solve the problems of high brittleness of resin cured products, insufficient operating time, weak waterproof and anti-corrosion properties of structural adhesives, and improve the dispersion and integrity of fillers. Excellent thixotropy and adhesive properties, waterproof and anti-corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

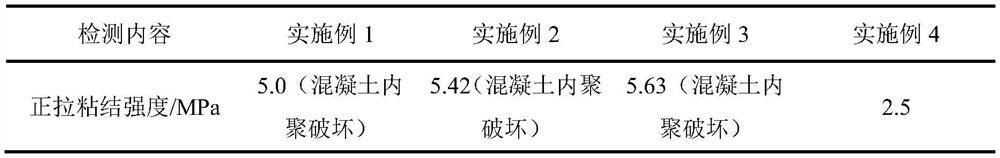

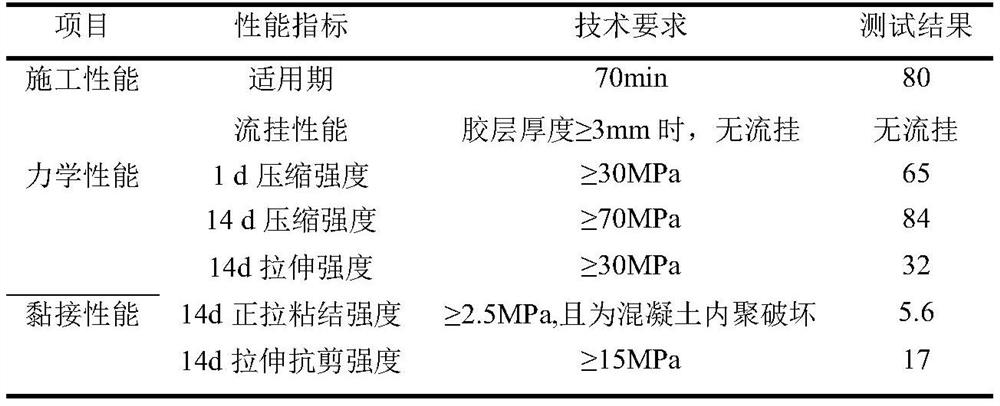

Examples

Embodiment 1

[0033] A summer slow-setting high-performance structural adhesive, mainly made of the following raw materials in parts by weight: 100 parts of E-51 epoxy resin, 30 parts of silicon micropowder, 20 parts of nano-calcium carbonate, 3 parts of chopped carbon fiber, and modified graphene 1 part, 20 parts of polyamide, 30 parts of aromatic amine, 2 parts of silane coupling agent, preferably, the type of silane coupling agent is KH-792, and the silica powder is 5000 mesh silica powder.

[0034] Modified graphene is made of graphene, dehydrated alcohol, silane coupling agent and ethanol, and its preparation method comprises the steps:

[0035] (1) 4 parts of graphene and 150 parts of absolute ethanol are added together in the beaker and magnetically stirred for 3 minutes and then dispersed by an ultrasonic cleaner for 30 minutes to obtain A solution;

[0036] (2) Put 20 parts of silane coupling agent into 100 parts of ethanol and magnetically stir for 3 minutes to obtain B solution; ...

Embodiment 2

[0043] A summer slow-setting high-performance structural adhesive, mainly made of the following raw materials in parts by weight: 100 parts of E-51 epoxy resin, 50 parts of silicon micropowder, 10 parts of nano-calcium carbonate, 4 parts of chopped carbon fiber, and modified graphene 1 part, 20 parts of polyamide, 30 parts of aromatic amine, 4 parts of silane coupling agent, preferably, the model of silane coupling agent is KH-792, silicon micropowder is 5000 mesh silicon micropowder, chopped carbon fiber length is 3mm, poly The amide is PA650, and the aromatic amine is H-113.

[0044] Adopt the preparation method of modified graphene of embodiment 1 to prepare modified graphene.

[0045] A preparation method of summer slow-setting high-performance structural adhesive, the steps are as follows:

[0046] Step 1. Put 3 parts of modified graphene in absolute ethanol solution, stir magnetically at room temperature for 5 minutes to prepare D mixed solution, add D mixed solution an...

Embodiment 3

[0050] A summer slow-setting high-performance structural adhesive, mainly made of the following raw materials in parts by weight: 100 parts of E-51 epoxy resin, 50 parts of silicon micropowder, 20 parts of nano-calcium carbonate, 5 parts of chopped carbon fiber, and modified graphene 3 parts, 20 parts of polyamide, 30 parts of aromatic amine, 3 parts of silane coupling agent, preferably, the model of silane coupling agent is KH-792, silicon micropowder is 5000 mesh silicon micropowder, chopped carbon fiber length is 3mm, poly The amide is PA650, and the aromatic amine is H-113.

[0051] Adopt the preparation method of modified graphene of embodiment 1 to prepare modified graphene.

[0052] A preparation method of summer slow-setting high-performance structural adhesive, the steps are as follows:

[0053] Step 1. Put 3 parts of modified graphene in absolute ethanol solution, stir magnetically at room temperature for 5 minutes to prepare D mixed solution, add D mixed solution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com