Microbial agent for efficiently degrading formaldehyde and preparation method of microbial agent

A microbial bacterial agent and microbial culture technology, which is applied in the field of microbial bacterial agent for efficient degradation of formaldehyde and its preparation, can solve the problems of inability to achieve efficient degradation of formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

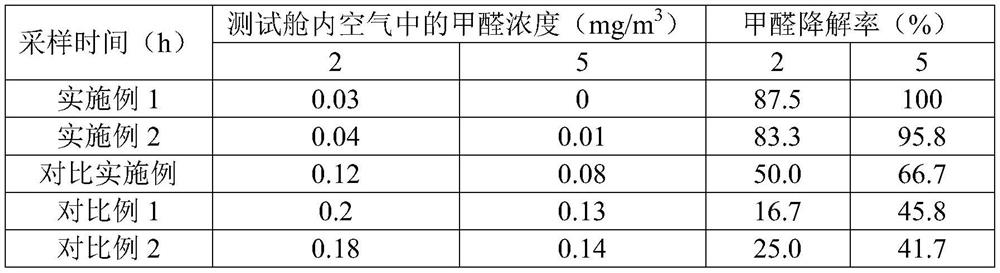

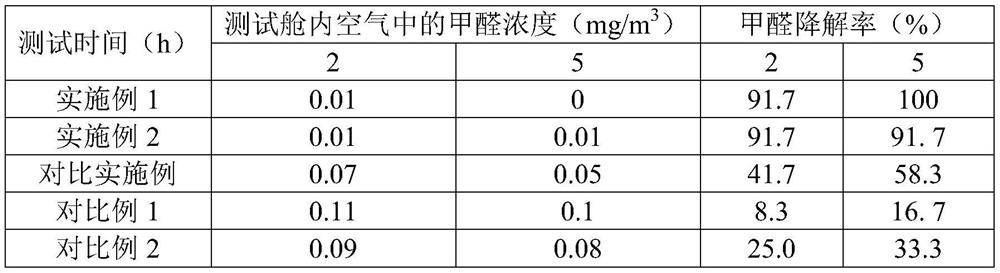

Examples

Embodiment 1

[0041] The application provides a preparation method of a microbial agent for efficiently degrading formaldehyde, comprising the following steps: S1, configuring a solid medium A, the formula of which is: beef extract 3g / L, peptone 10g / L, sodium chloride 5g / L , potassium dihydrogen phosphate 0.6g / L, dipotassium hydrogen phosphate 0.85g / L, agar 20g / L, and trace element solution 550μL / L. The trace element solution is prepared by dissolving the following raw materials in deionized water: boric acid 6g / L, copper chloride 0.2g / L, cobalt chloride 4g / L, nickel chloride 0.4g / L, zinc sulfate 2g / L, chlorine Manganese chloride 0.6g / L.

[0042] Configure solid LB medium, its formula is: tryptone 10g / L, yeast extract 5g / L, sodium chloride 10g / L, agar 20g / L.

[0043] Configure solid medium B, its formula is: sodium malate 1.0g / L, sodium acetate 1.0g / L, ammonium chloride 1.0g / L, potassium dihydrogen phosphate 1.0g / L, calcium chloride 0.1g / L, Sodium bicarbonate 2.9g / L, magnesium chloride 0....

Embodiment 2

[0051] The difference between this example and Example 1 is that in this example, in step S2, the three strains of Methylobacterium MR1, Pseudomonas IOFA1 and Rhodopseudomonas palustris LY-6 were inoculated in liquid medium A After incubation, culture in the dark until the total number of viable bacteria reached 2×10 9 cells / mL to obtain the microbial culture solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com