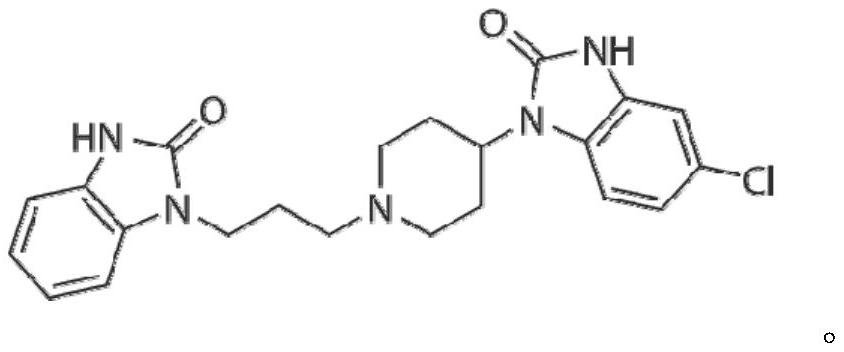

Domperidone tablet and preparation method thereof

A technology for dipperidone tablets and domperidone, which is applied in the direction of pharmaceutical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., which can solve the problem of unstable content uniformity of active ingredients and unfavorable products to exert their efficacy, etc. problems, to achieve consistent appearance and dissolution curve, excellent appearance, and excellent dissolution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

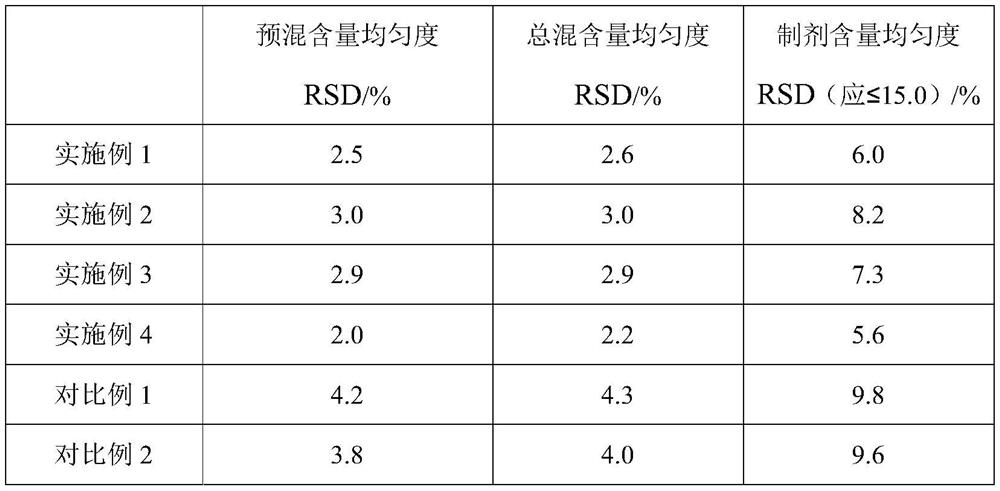

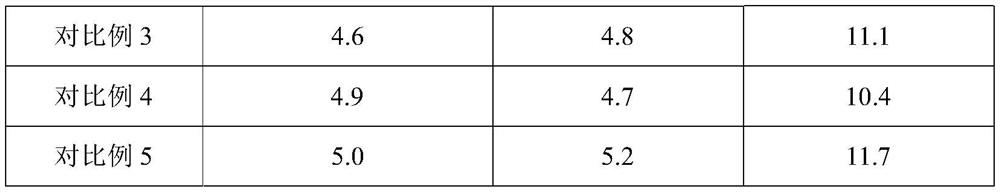

Embodiment 1

[0062]A domperidone tablet, in parts by weight, comprising the following components: 1 part of domperidone, 6 parts of lactose, 2 parts of pregelatinized starch, 0.5 parts of low-substituted hydroxypropyl cellulose, 0.6 parts of povidone K30, and dodecane 0.01 part of sodium sulphate, 0.1 part of silicon dioxide, 0.08 part of magnesium stearate.

[0063]The preparation process of the above-mentioned domperidone tablet includes the following steps:

[0064]1) Premix domperidone and the same amount of lactose (1 part) for 2 minutes to obtain mixture A;

[0065]2) Take the same amount of lactose as domperidone, crush it in a pulverizer, and pass through a 100-mesh sieve to obtain substance B;

[0066]3) The mixture A is crushed in a pulverizer and passed through a 100-mesh sieve 3 times to obtain a mixture C;

[0067]4) Crush substance B again in the pulverizer, pass through a 100-mesh sieve once, collect the sieved substance B (including the residual mixture C in the pulverizer cavity), after collec...

Embodiment 2

[0073]A domperidone tablet, calculated in parts by weight, comprising the following components: 1 part of domperidone, 10 parts of microcrystalline cellulose, 3.5 parts of starch, 0.8 parts of sodium carboxymethyl starch, 0.9 parts of polyethylene glycol (molecular weight 2000) , 0.0045 parts of sodium dodecyl sulfonate, 0.05 parts of talc, 0.13 parts of magnesium stearate.

[0074]The preparation process of the above-mentioned domperidone tablet includes the following steps:

[0075]1) Premix domperidone and the same amount of microcrystalline cellulose for 10 minutes to obtain mixture A;

[0076]2) Take another microcrystalline cellulose equivalent to domperidone, pulverize it in a pulverizer, and pass through a 60-mesh sieve to obtain substance B;

[0077]3) The mixture A is crushed in a pulverizer and passed through a 60-mesh sieve to obtain the mixture C;

[0078]4) The substance B is pulverized again in the pulverizer, and it passes through a 60-mesh sieve 5 times, and the sieved substance B...

Embodiment 3

[0084]A domperidone tablet, in parts by weight, comprising the following components: 1 part of domperidone, 3 parts of microcrystalline cellulose, 0.5 part of pregelatinized starch, 0.1 part of sodium carboxymethyl starch, 0.3 part of povidone K30, ten 0.02 parts of sodium dialkyl sulfonate, 0.15 parts of sodium stearyl fumarate, and 0.03 parts of magnesium stearate.

[0085]The preparation process of the above-mentioned domperidone tablet includes the following steps:

[0086]1) Premix domperidone and the same amount of microcrystalline cellulose for 5 minutes to obtain mixture A;

[0087]2) Take the same amount of microcrystalline cellulose as domperidone, pulverize it in a pulverizer, and pass through an 80-mesh sieve to obtain substance B;

[0088]3) The mixture A is pulverized in a pulverizer and passed through an 80-mesh sieve to obtain the mixture C;

[0089]4) The substance B is pulverized again in the pulverizer, and passed through an 80-mesh sieve three times, and the sieved substance B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com